Pipeline-used expansion joint with second-level pressurization structure

An expansion joint with its own technology, applied in the field of expansion joints, can solve the problems of large internal and external pressure difference, property loss, short fatigue life, etc., and achieve the effect of improving the use pressure occasion, meeting the demand of high-pressure pipelines, and meeting the requirements of temperature compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

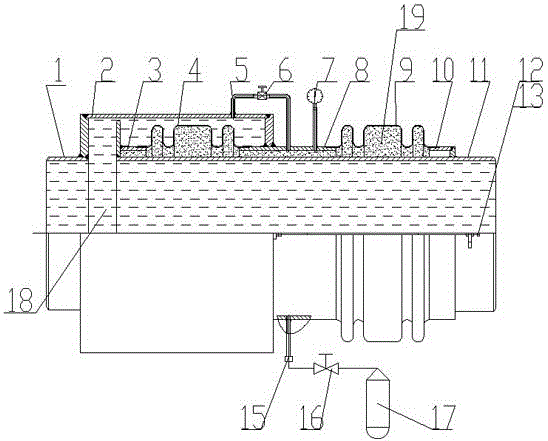

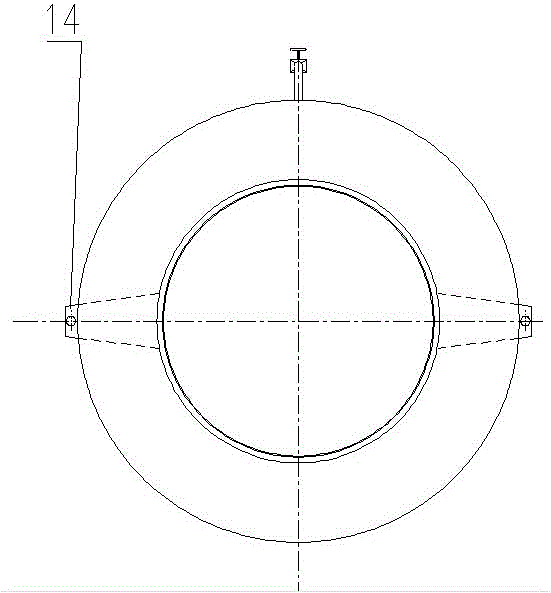

[0023] Such as figure 1 and figure 2 The pipeline expansion joint with self-contained secondary pressure shown in the figure is an external pressure type, and the waveform parameters and wave numbers of the working bellows 4 and the protection bellows 9 are the same. The inlet pipe assembly 1, the outer pipe 2, the middle pipe assembly 8, the working bellows 4, the inner end ring assembly 3, and the outlet pipe 11 form a fluid medium space, and the working bellows bear the high external pressure of the working fluid medium. The protection bellows 9 is welded with the outer end ring assembly 10 to form a secondary pressurization chamber, the working bellows bears the internal pressure set by the pressurization medium, and the protection bellows also bears the internal pressure of the pressurization medium. In this way, the pressure difference between the inner and outer surfaces of the working bellows will be reduced, and the stress situation will be greatly improved, which i...

Embodiment 2

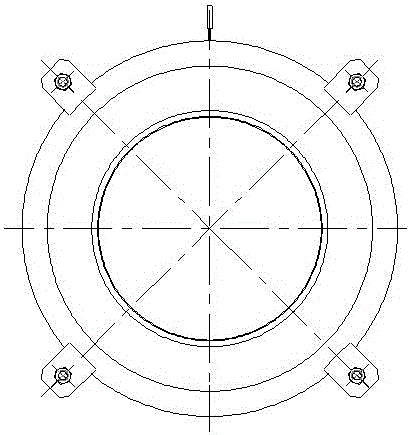

[0026] Such as image 3 and Figure 4 As shown, the pipeline expansion joint adopts the internal pressure type, the inlet pipe assembly 1, the working bellows 4, and the outlet pipe 11 form a fluid medium space, and the working bellows bears the high internal pressure of the working fluid medium. The protection bellows 9 is welded with the outer pipe 2 to form a secondary pressurization chamber, the working bellows bears the external pressure set by the pressurization medium, and the protection bellows bears the internal pressure of the pressurization medium. In this way, the pressure difference between the inner and outer surfaces of the working bellows will be reduced, and the stress situation will be greatly improved, which is beneficial to improving the service life of the working bellows.

[0027] The pressurized medium 19 is gas, which is filled by the external pressurized gas cylinder 17 through the pressurized valve 16 and the plugging pipe 15 . The pressure chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com