A method for manufacturing a curved surface transparent part with variable thickness

A manufacturing method and technology of transparent parts, which is applied in the manufacture of variable-thickness curved surface transparent parts and high-precision fields, can solve the problems of long manufacturing process and high production cost, reduce molding cycle, reduce production cost, and improve residual stress Effects of Level and Dimensional Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] (1) Preliminary preparation: put the OQ2720 polycarbonate pellets in a vacuum dehumidification dryer, and dry them at 120°C for 4 hours. The dried pellets enter the screw through the hopper and are plasticized. The plasticized back pressure is 10bar. The plasticizing temperature is divided into seven areas from the hopper to the nozzle: 160°C, 220°C, 260°C, 280°C, 300°C, 300°C and 290°C;

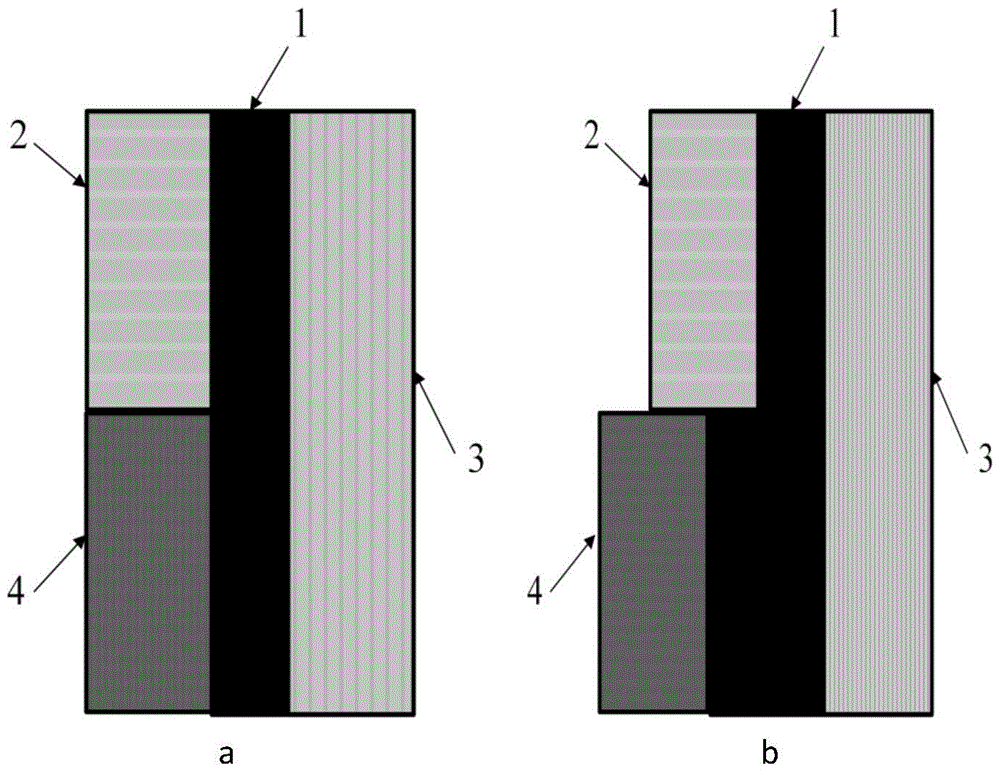

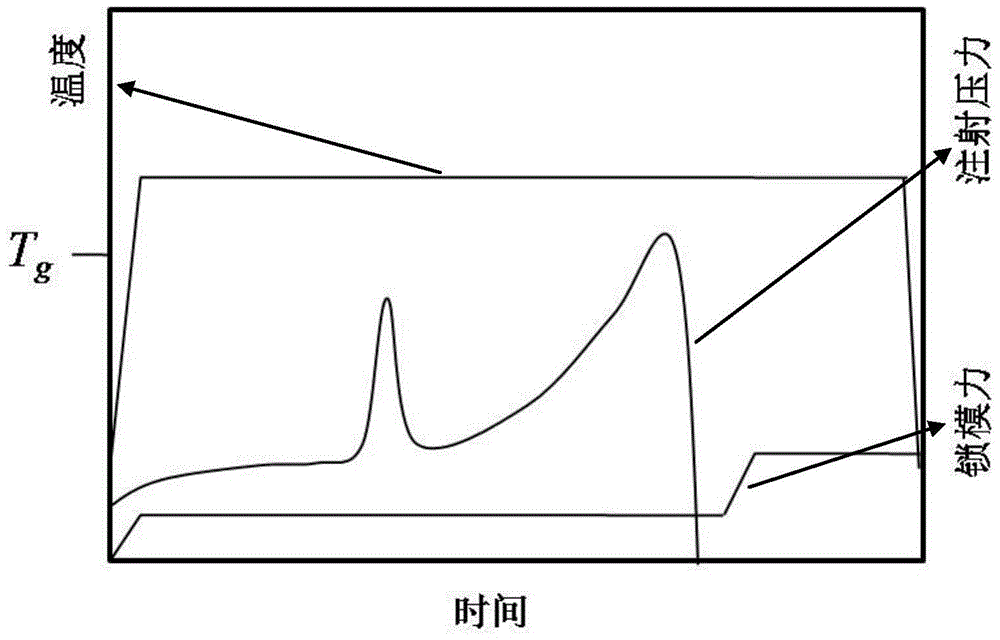

[0028] (2) Injection - one-time overall injection compression: the temperature of the movable mold 2, fixed mold 3 and insert 4 in the thick-walled area of the part must be maintained at 160 °C, and the high-temperature melt 1 in step (1) is pushed by a screw 20mm / The speed of s is injected into the mold with a cavity expansion gap of 5mm, and the pressure is maintained for a short time of 0.5s to ensure that the melt will not flow back. At the same time, the mold is closed at a speed of 30mm / s to form a mold cavity with a thickness of 15mm. At this stage As the clamping force is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com