Stress-reducing laser chip structure and heat sink structure and preparation method thereof

A chip structure and laser technology, applied in the direction of lasers, laser parts, semiconductor lasers, etc., can solve the problem of not being able to fully meet the requirements of high-power semiconductor lasers, limiting the application of high-power semiconductor laser bars, and large stress of semiconductor laser bars, etc. problem, to achieve the effect of low bending, stress reduction and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

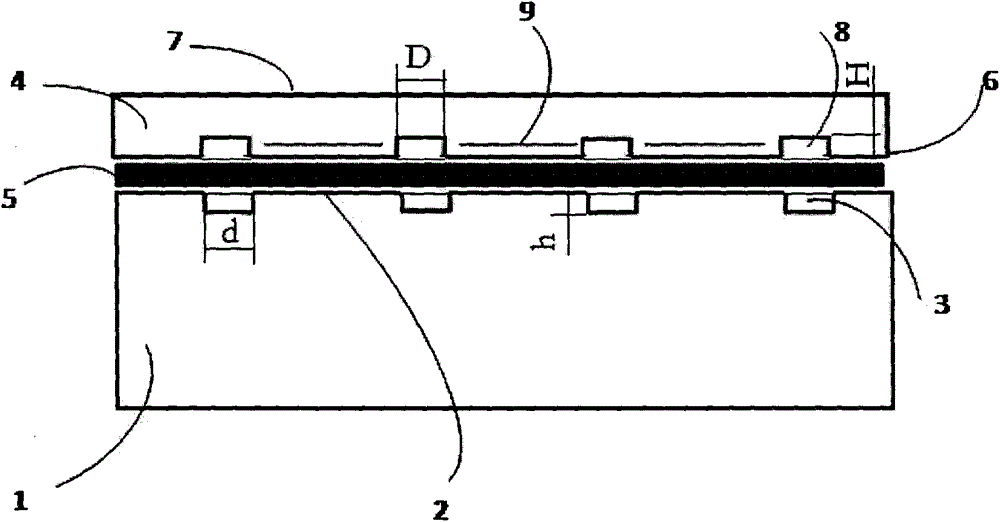

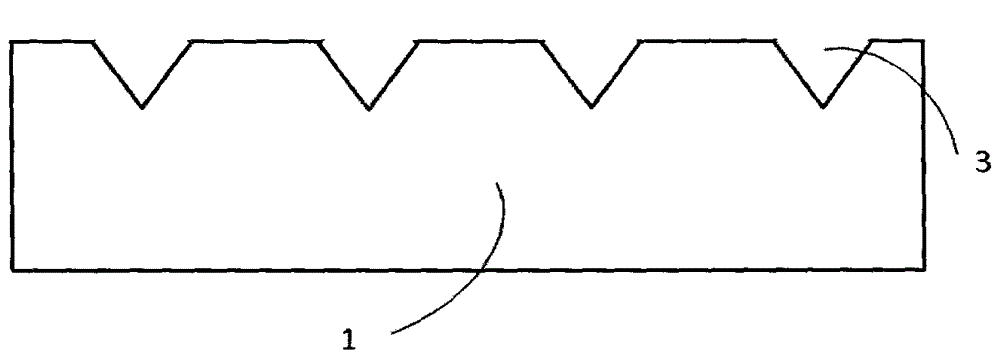

[0046] like figure 1 As shown, a stress-reducing laser chip structure includes a laser chip main body 4, the laser chip main body 4 has a positive electrode 6 and a negative electrode 7 electrically connected to an external electrode, a plurality of light emitting parts 9 are arranged on the positive electrode 6, and the light emitting parts 9 is provided with a first groove 8, and also includes a heat sink structure, the heat sink structure includes a heat sink body 1, the front side 2 of the heat sink body 1 is welded on the positive electrode 6 of the laser chip body 4 through a solder layer 5, and the heat sink structure includes a heat sink body 1. A second groove 3 is formed on the part of the sinker body 1 corresponding to the first groove 8 of the laser chip body 4 , and the second groove 3 corresponds to the first groove 8 one by one.

[0047]The heat sink body 1 is made of metal or ceramic or diamond or metal matrix composite. The metal matrix composite material can...

Embodiment 2

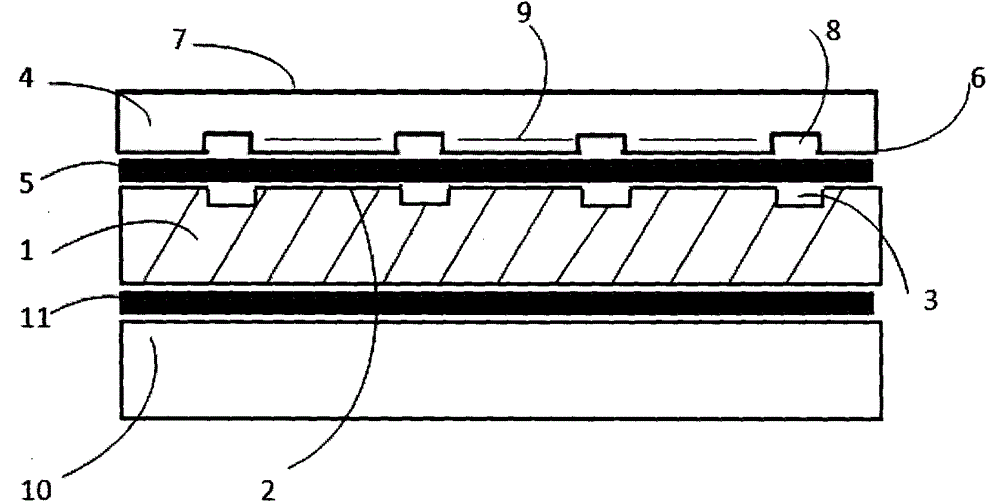

[0065] like figure 2 As shown, a stress-reducing laser chip structure includes a laser chip main body 4, the laser chip main body 4 has a positive electrode 6 and a negative electrode 7 electrically connected to an external electrode, a plurality of light emitting parts 9 are arranged on the positive electrode 6, and the light emitting parts 9 is provided with a first groove 8, and also includes a heat sink structure, the heat sink structure includes a heat sink body 1, the front side 2 of the heat sink body 1 is welded on the positive electrode 6 of the laser chip body 4 through a solder layer 5, and the heat sink structure includes a heat sink body 1. A second groove 3 is formed on the part of the sinker body 1 corresponding to the first groove 8 of the laser chip body 4 , and the second groove 3 corresponds to the first groove 8 one by one. The heat sink structure further includes a metal structure layer 10 , and the back surface of the heat sink body 1 is plated on the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com