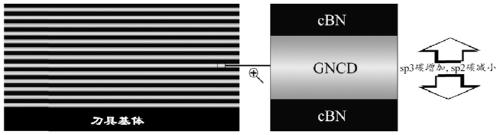

Preparation method of GNCD-CBN nanocomposite multi-layer coating tool with toughening mechanism

A nano-composite, multi-layer coating technology, applied in the direction of coating, metal material coating process, superimposed layer plating, etc., can solve the problems of poor bonding performance between coating and cemented carbide substrate, and low coating toughness. , to achieve the effect of improving wear resistance, improving coating toughness and extending tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Such as Figure 1-4 shown.

[0034] A preparation method of a GNCD-cBN nanocomposite multi-layer coating cutter with a toughening mechanism, comprising the following steps:

[0035] 1) Substrate pretreatment: use WC-Co cemented carbide blades as the substrate material, now place the WC-Co cemented carbide blades in acetone solution for ultrasonic cleaning for 15 minutes, and then put them in K 3 Fe(CN) 6 :KOH:H 2 O was ultrasonically cleaned for 20 minutes in a solution mixed with a mass ratio of 1:1:10, then soaked in a mixed solution with a concentration of 65% nitric acid and 36% hydrochloric acid at a volume ratio of 1:3 for 5 minutes, and finally Ultrasonic grinding with diamond micropowder suspension for 25 min, washing with deionized water, and drying to obtain the substrate.

[0036] 2) Microwave chemical vapor deposition gradient nano-diamond: put the pretreated substrate in the microwave chemical vapor deposition chamber, turn on the chiller, use a mechani...

Embodiment 2

[0042] Such as Figure 1-4 shown.

[0043] A preparation method of a GNCD-cBN nanocomposite multi-layer coating cutter with a toughening mechanism, comprising the following steps:

[0044] 1) Substrate pretreatment: use WC-Co cemented carbide blades as the substrate material, now place the WC-Co cemented carbide blades in acetone solution for ultrasonic cleaning for 15 minutes, and then put them in K 3 Fe(CN) 6 :KOH:H 2 O was ultrasonically cleaned for 20 minutes in a solution mixed with a mass ratio of 1:1:10, then soaked in a mixed solution with a concentration of 65% nitric acid and 36% hydrochloric acid at a volume ratio of 1:3 for 5 minutes, and finally Ultrasonic grinding with diamond micropowder suspension for 25 min, washing with deionized water, and drying to obtain the substrate.

[0045] 2) Hot wire chemical vapor deposition gradient nano-diamond: place the pretreated substrate in the hot wire chemical vapor deposition chamber, place the substrate about 4-6mm be...

Embodiment 3

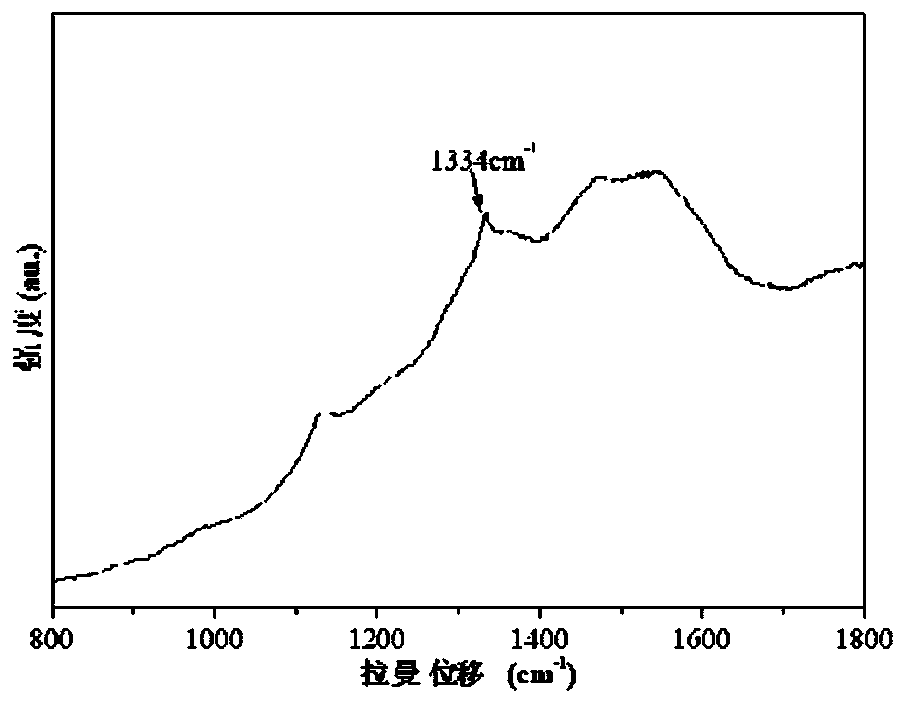

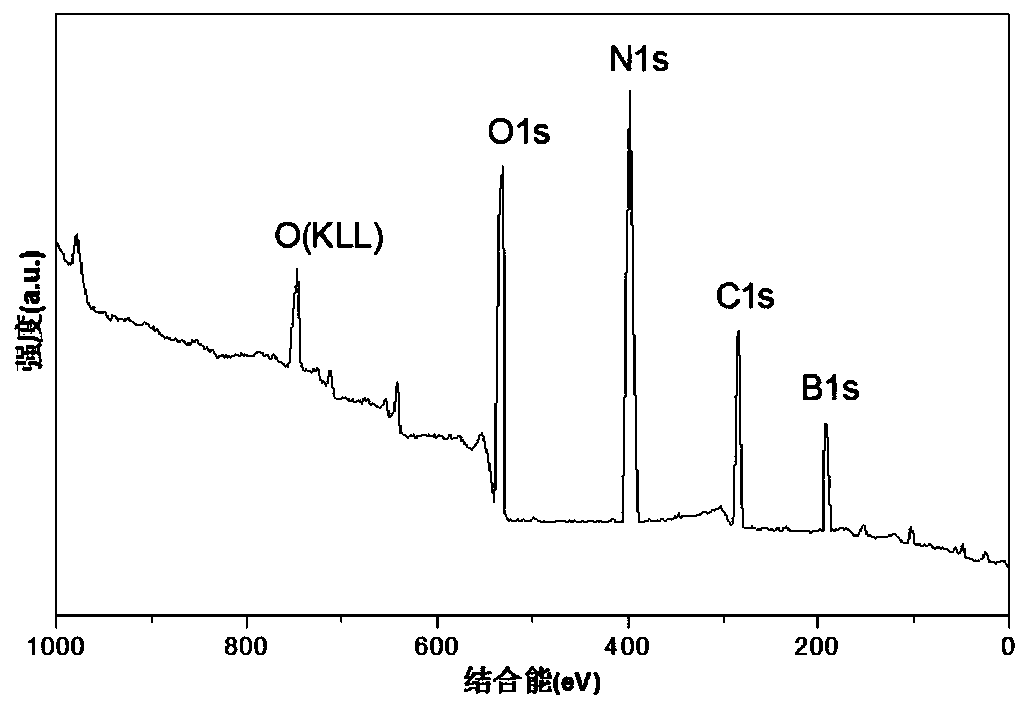

[0050] The difference between this embodiment and Embodiments 1 and 2 is that the parameters used during substrate pretreatment meet the following conditions: use WC-Co cemented carbide blades as the substrate material, and place the WC-Co cemented carbide blades in an acetone solution Ultrasonic cleaning for 10 to 15 minutes, and then put in the K 3 Fe(CN) 6 :KOH:H 2 O in a solution mixed with a mass ratio of 1: 0.8 to 1.2: 8 to 12 and ultrasonically cleaned for 15 to 30 minutes, and then mixed with 65% nitric acid and 36% hydrochloric acid at a volume ratio of 1: 2 to 4 Soak the resulting mixed solution for not less than 5 minutes, and finally use the diamond nano powder suspension to ultrasonically clean for 15 to 30 minutes, and after cleaning with deionized water, dry it in a nitrogen environment for later use to obtain a substrate. All the other embodiments one and two are the same, and the performance of the deposited coating is as follows: Figure 2-4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com