Halogen-free flame retardant heat conduction polyurethane pouring sealant and preparation method thereof

A technology of polyurethane and potting glue is applied in the preparation of halogen-free flame retardant and thermally conductive polyurethane potting glue. The problems such as the decline of the mechanical properties of the glue, to achieve the effect of excellent thermal conductivity, small environmental impact, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

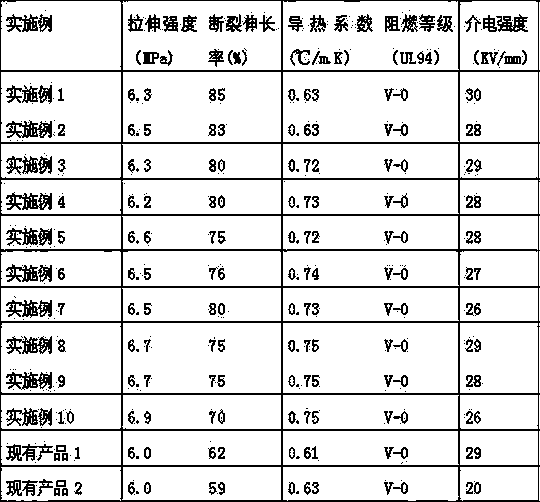

Examples

Embodiment 1

[0029] Preparation of component A: Add 42g of castor oil, 8g of nano-magnesium hydroxide, 9g of toluene diphenyl phosphate, 40g of aluminum oxide, 0.2g of dibutyltin dilaurate, and 0.8g of defoamer into the reaction kettle, and heat to 110~ Dehydrate at 120°C for 2 hours under vacuum, drop to normal temperature under nitrogen protection, and seal the package.

[0030] Preparation of component B: Weigh 25g of liquefied 2,4-toluene diisocyanate as component B, and seal the package.

[0031] Mix components A and B uniformly at a weight ratio of 100:25 to obtain the finished product.

[0032] When in use, pour the finished polyurethane potting compound on the electronic components that need to be potted, vacuumize for 3~5min, and then cure at room temperature for 24h~48h.

Embodiment 2

[0034] Preparation of component A: Add 36g of castor oil, 10g of aluminum hydroxide, 13g of isopropyl diphenyl phosphate, 40g of aluminum oxide, 0.2g of stannous octoate, and 0.8g of defoamer into the reaction kettle, and heat to 110~120 ℃, take it off for 3 hours in a vacuum state, lower it to normal temperature under the protection of nitrogen, and seal the package.

[0035] Preparation of component B: Weigh 20 g of liquefied 2,6-toluene diisocyanate as component B, and seal the package.

[0036] Mix components A and B uniformly at a weight ratio of 100:20 to obtain the finished product.

[0037] When in use, pour the finished polyurethane potting compound on the electronic components that need to be potted, vacuumize for 3~5min, and then cure at room temperature for 24h~48h.

Embodiment 3

[0039] Preparation of component A: castor oil 33g, melamine polyphosphate 14g, isopropyl diphenyl phosphate 9g, aluminum oxide 30g, aluminum nitride 10g, dibutyltin dilaurate 0.1g, stannous octoate 0.1g, defoamer Add 0.8g into the reaction kettle, heat to 110~120°C, dehydrate under vacuum for 2.5 hours, lower to normal temperature under nitrogen protection, and seal the package.

[0040] Preparation of component B: Weigh 15 g of liquefied polymethylene polyphenyl polyisocyanate as component B, and seal the package.

[0041] Mix components A and B uniformly at a weight ratio of 100:15 to obtain the finished product.

[0042] When in use, pour the finished polyurethane potting compound on the electronic components that need to be potted, vacuumize for 3~5min, and then cure at room temperature for 24h~48h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com