Low-density thermal conductive silicone pad and preparation method thereof

A heat-conducting silica gel and low-density technology, which is applied in the field of low-density heat-conducting silica gel sheet and its preparation, can solve the problems of restricting wide application, and achieve the effects of reducing battery weight, wide application prospects, excellent flame retardancy and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

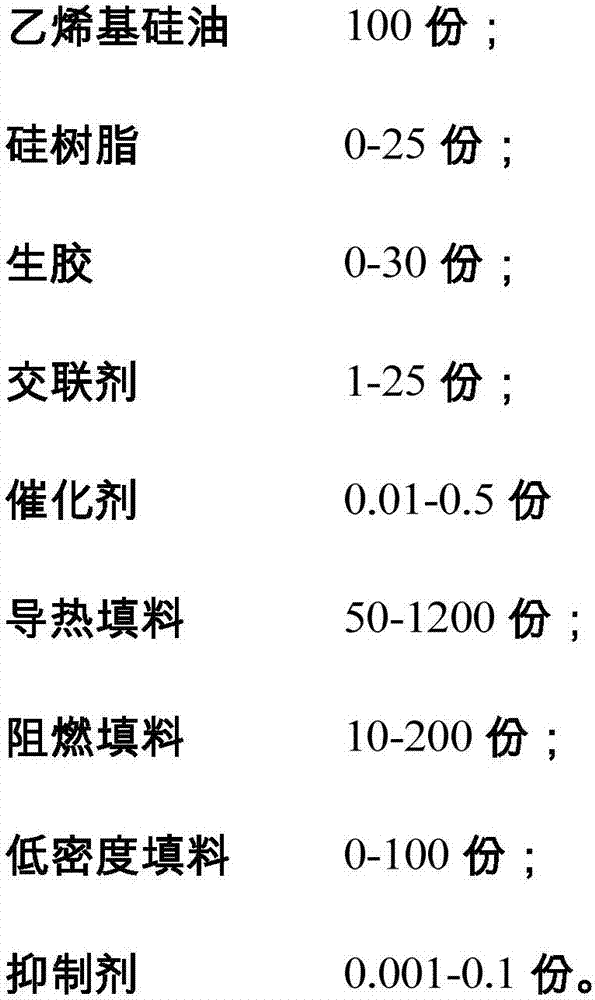

[0032] A low-density thermally conductive silica gel sheet, comprising the following components by weight:

[0033]

[0034] The preparation process of the above-mentioned low-density thermal silica gel sheet is as follows:

[0035] (1) Mixing and plasticizing, under the condition of 110 degrees Celsius, vinyl silicone oil, thermally conductive filler, flame retardant filler, reinforcing filler, and low-density filler were added to a vacuum kneader, and blended for 2 hours to obtain a masterbatch; After cooling to room temperature, add catalyst, inhibitor, vacuumize 1H and mix well;

[0036] (2) calendering, put the semi-finished product made in step (1) into a calender, adjust the cylinder and the scraper, and roll it into a set thickness through the calender;

[0037] (3) Prepare a low-density heat-conducting silica gel sheet, transport the gasket rolled in step (2) to an oven along with the tunnel, and vulcanize it into a sheet at high temperature; according to the vulc...

Embodiment 2

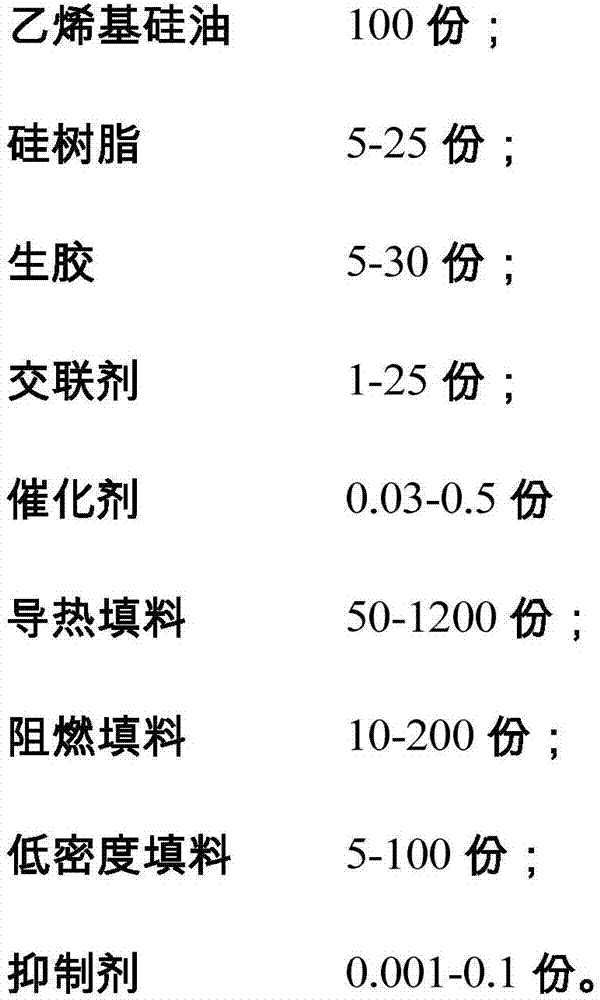

[0039] A low-density thermally conductive silica gel sheet, comprising the following components by weight:

[0040]

[0041] The preparation process of the above-mentioned low-density thermal silica gel sheet is as follows:

[0042] (1) To prepare the base material, add 100 parts of vinyl silicone oil to the vacuum kneader at room temperature at 25°C, start the kneader; then add 180 parts of boron nitride, 20 parts of aluminum hydroxide, and 8 parts of gas phase white carbon Black and 38 parts of hollow glass microspheres were evenly added to vinyl silicone oil, and blended and kneaded for 6 hours under the condition of vacuum degree of 0.06MPa to obtain the base material;

[0043] (2) To prepare component A and component B, divide the base material into two parts according to this example of 1:1; control the temperature at 25±3°C, add 0.01 part of chloroplatinic acid-isopropanol to one of the base materials , stirred for 100 minutes to prepare component A; control the tem...

Embodiment 3

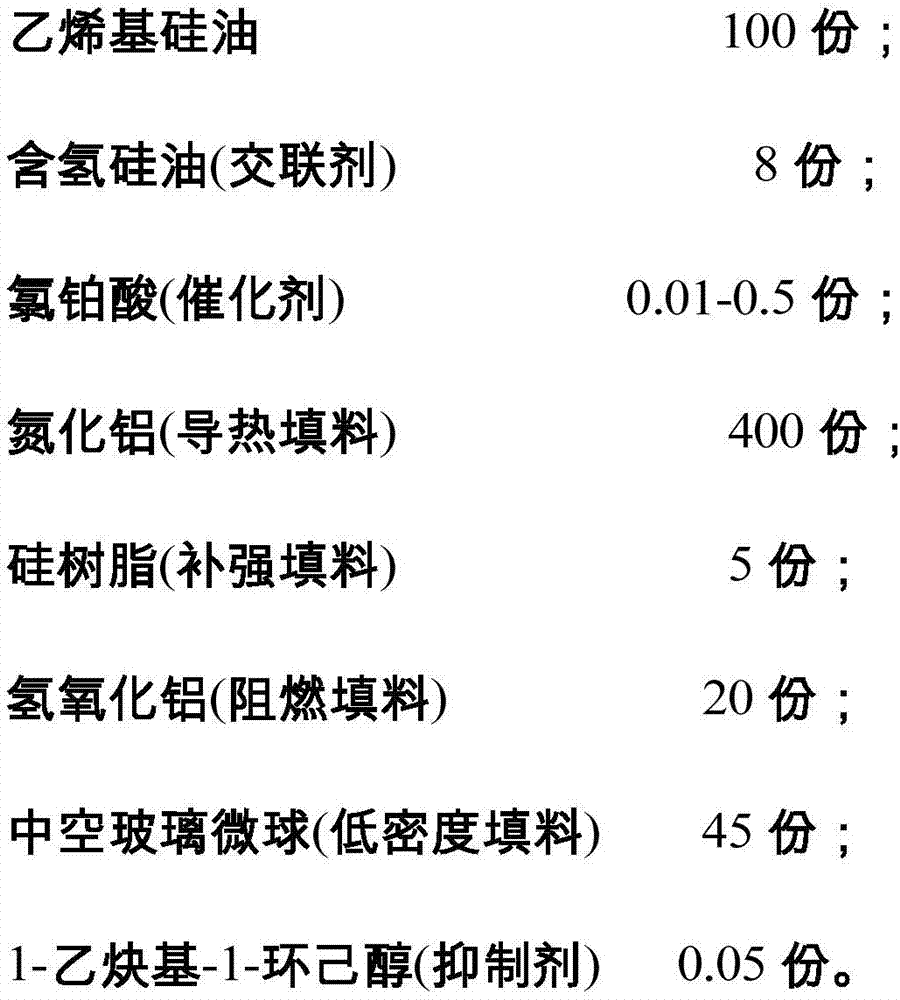

[0046] A low-density thermally conductive silica gel sheet, comprising the following components by weight:

[0047]

[0048]

[0049] The preparation process of the above-mentioned low-density thermal silica gel sheet is as follows:

[0050] (1) To prepare the base material, add 100 parts of vinyl silicone oil to the vacuum kneader at room temperature at 25°C, start the kneader; then add 200 parts of boron nitride, 30 parts of zinc borate, and 10 parts of fumed silica and 45 parts of hollow phenolic spheres were uniformly added to vinyl silicone oil, and blended and kneaded for 6 hours under the condition of vacuum degree 0.08MPa to obtain the base material;

[0051](2) To prepare component A and component B, divide the base material into two parts according to the ratio of 1:1; control the temperature at 25±3°C, add 0.3 parts of Castel catalyst to one of the base materials, stir for 80min, Prepare component A; control the temperature at 25±3°C, add 14 parts of hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com