Foam metal composite phase change material heat storage temperature-difference power generation device

A composite phase change material and metal foam technology, which is applied in the field of metal foam composite phase change material heat storage and thermoelectric power generation devices, to achieve the effects of easy acquisition, improved thermal stability, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

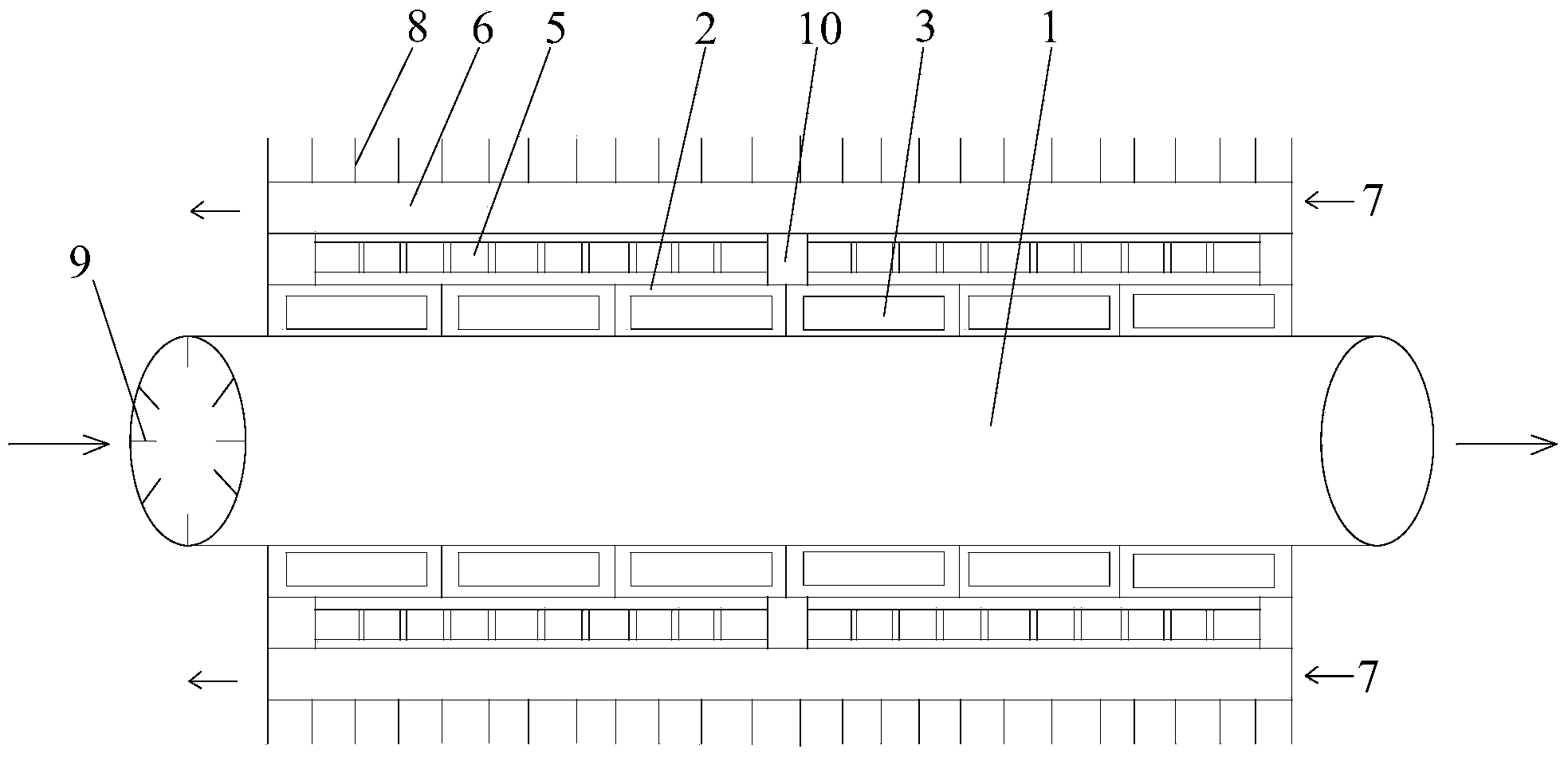

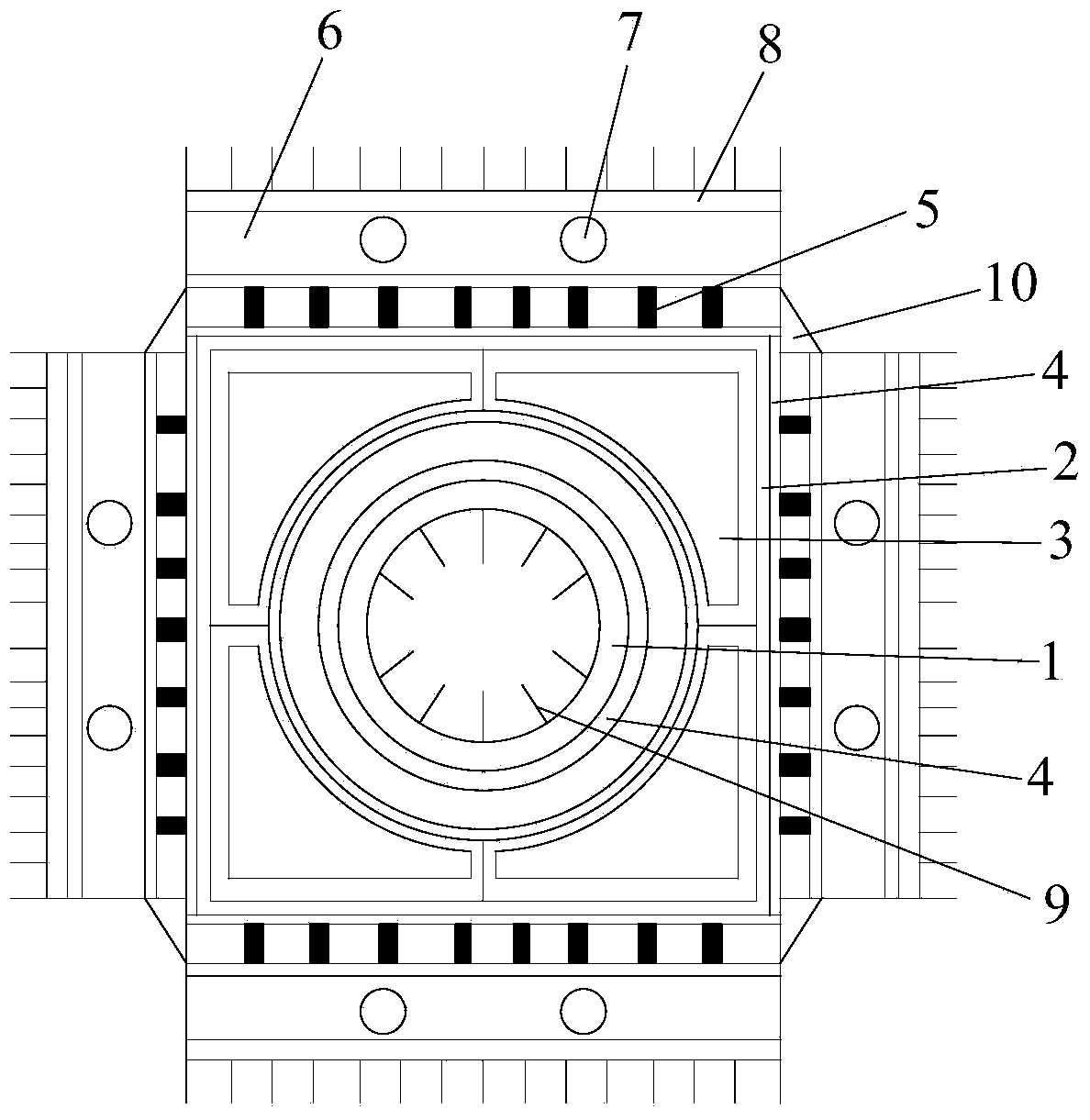

[0027] The present invention provides a metal foam composite phase change material heat storage thermoelectric power generation device, such as figure 1 , figure 2 shown.

[0028] The outer wall of the high-temperature flue gas carbon steel pipeline 1 is equipped with a small partition sealed carbon steel container 2, and the small partition sealed carbon steel container 2 is filled with a foamed metal composite phase change energy storage material 3, which is a foam metal Cu as a skeleton, and the phase change material for KHF 2 , the phase transition temperature is 196°C. The small partition sealed container 2 is closely connected with the hot end of the thermoelectric power generation module 5 through the thermal conductive glue 4 , and the cold end of the thermoelectric power generation module 5 is connected with the heat dissipation block 6 . The heat dissipation block 6 is connected with cooling circulating water 7 , and its outer side is connected with heat dissipat...

Embodiment 2

[0032] This embodiment applies a metal foam composite phase change material heat storage temperature difference power generation device provided in Example 1. The difference is that the small partition sealed container 2 is made of aluminum alloy material; the small partition sealed aluminum alloy container 2 is filled with foam metal composite The phase change energy storage material 3 is Al foam metal as the skeleton, the phase change material is AlCl3, and the phase change temperature is 192°C; the AlCl3 phase change material accounts for 85% of the total weight; the high temperature flue gas aluminum alloy pipe 1 is equipped with aluminum alloy fins 9. The working engineering of embodiment 2 is identical with embodiment 1.

Embodiment 3

[0034] This embodiment applies a metal foam composite phase change material heat storage temperature difference power generation device provided in Example 1. The difference is that the small partition sealed container 2 is made of copper alloy material; the small partition sealed copper alloy container 2 is filled with foam metal composite The phase change energy storage material 3 is made of Cu foam metal as the skeleton, the phase change material is 50% LiF / 50% LiOH, and the phase change temperature is 427°C; the phase change material accounts for 80% of the total weight; the internal assembly of the high temperature flue gas copper alloy pipe 1 There are copper alloy ribs 9. The working engineering of embodiment 3 is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com