Even heating board and heat radiating device

A technology of soaking plate and bottom plate, used in cooling/ventilation/heating transformation, electrical components, electrical solid devices, etc., can solve problems such as lack, and achieve the effect of solving heat dissipation problems, reducing thermal resistance, and strengthening reflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

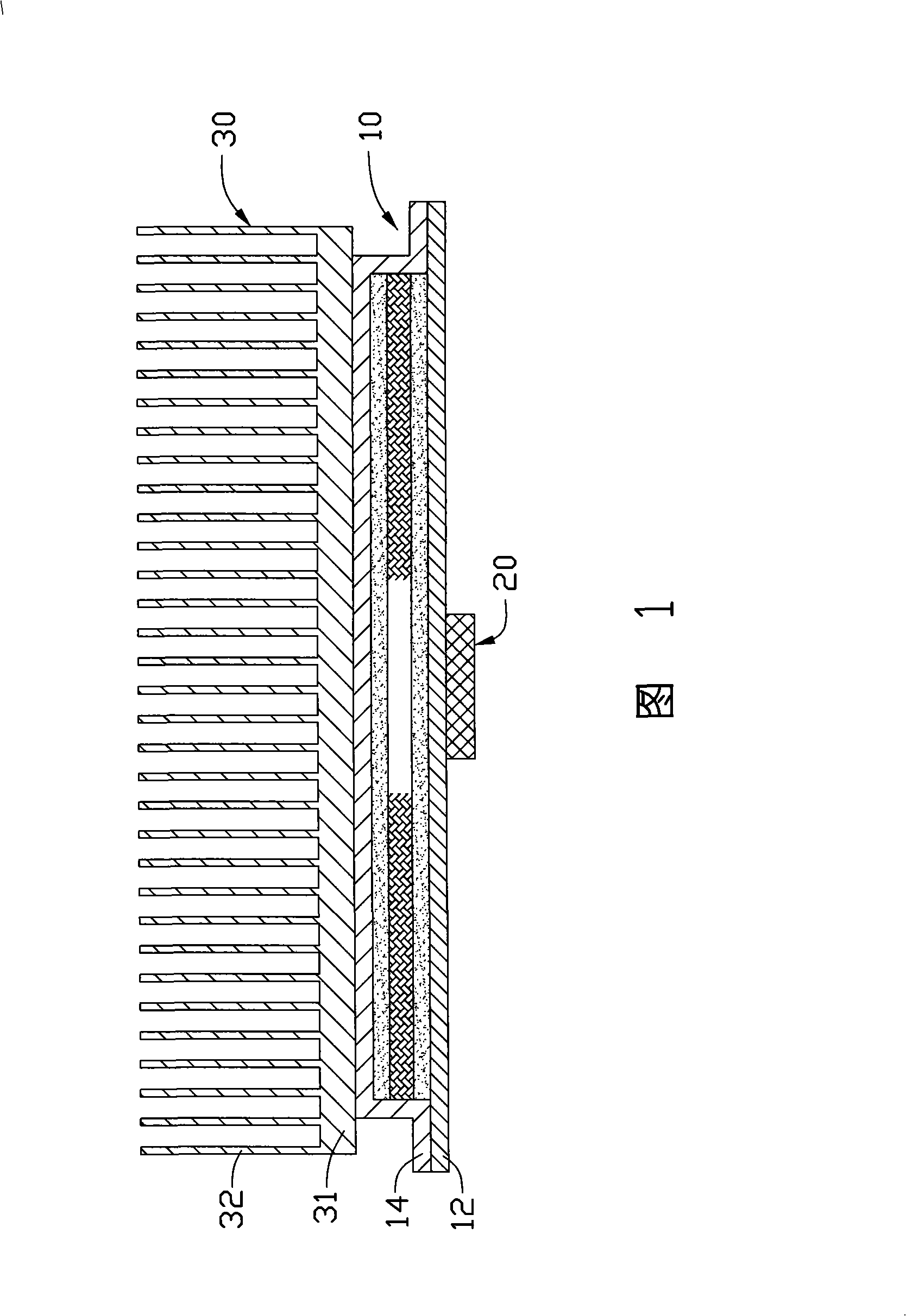

[0014] As shown in FIG. 1 , a preferred embodiment of the heat dissipation device of the present invention includes a vapor chamber 10 , an electronic component 20 attached to the lower side of the vapor chamber 10 , and a radiator located on the upper side of the vapor chamber 10 . device 30, wherein the electronic component 20 can be a computer central processing unit, a north bridge chip, a graphic video array or a light emitting diode, etc.

[0015] The heat sink 30 is made of metal with high thermal conductivity, such as copper, aluminum, etc., and includes a flat base 31 and a plurality of heat dissipation fins 32 extending upward from the base 31. The heat dissipation fins 32 can provide The larger heat dissipation area dissipates the heat generated by the electronic components 20 to the environment in a timely manner. The heat sink 30 is not limited to the structures and shapes disclosed in the figures.

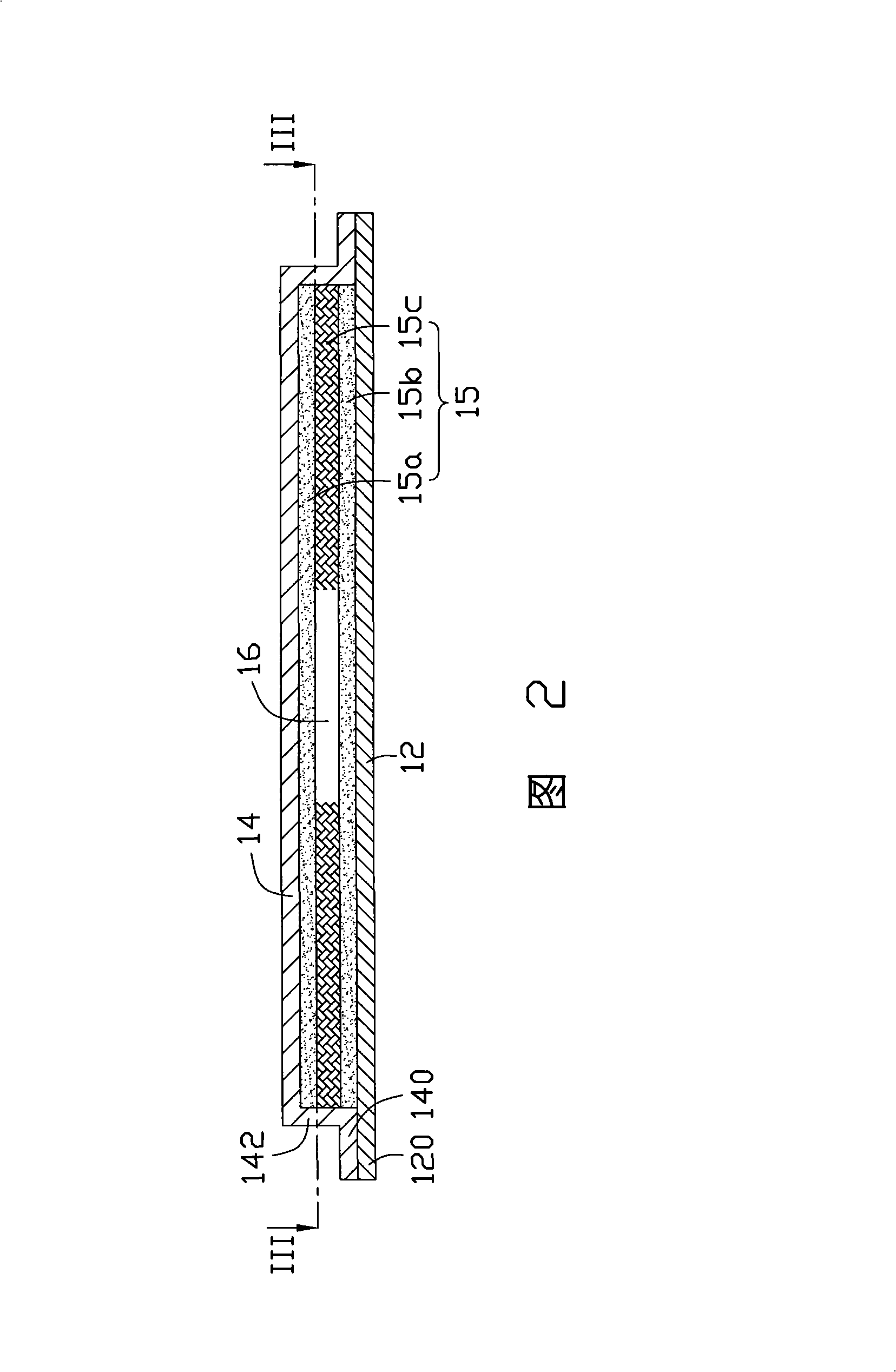

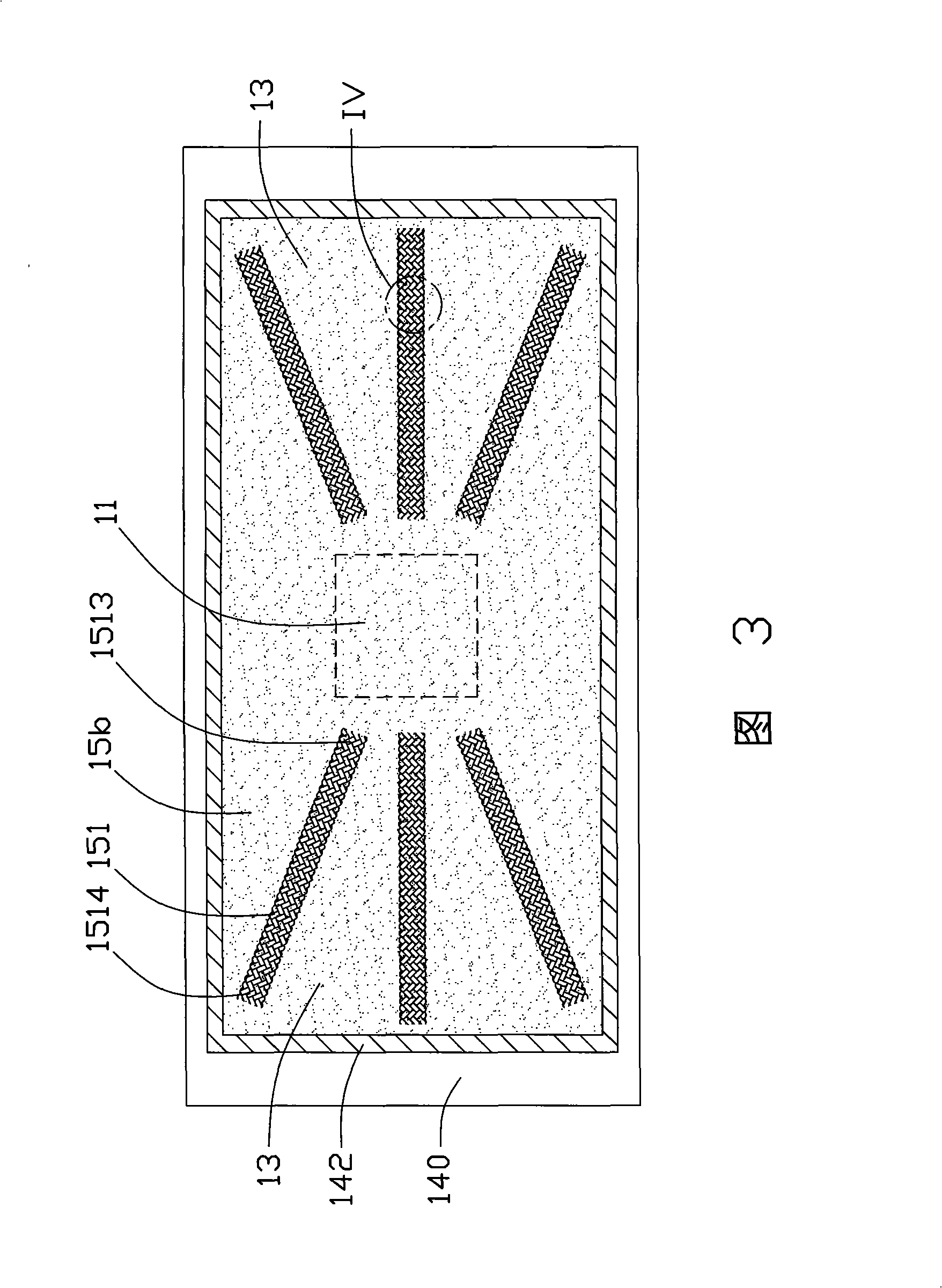

[0016] As shown in FIGS. 2 and 3 , the vapor chamber 10 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com