In-situ polymerization preparation method of spinning-level high-heat-conductivity graphene/nylon composite material

A technology of nylon composite materials and high thermal conductivity graphite, which is applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of poor dispersion and easy agglomeration of graphene, and achieve good thermal conductivity and good spinning performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

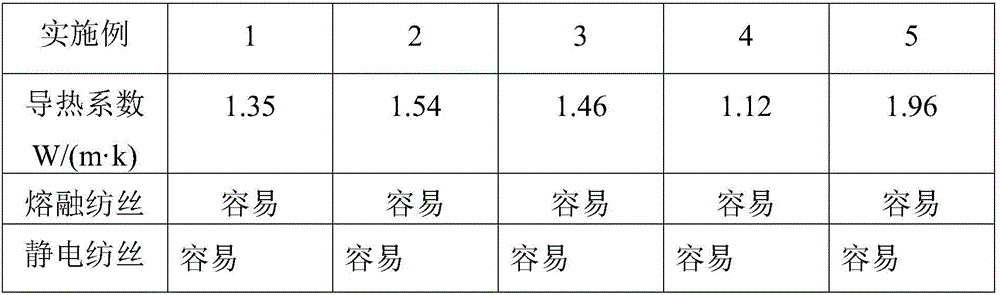

Examples

Embodiment 1

[0027] Synthesis of Graphene Oxide:

[0028] (1) The expanded graphite sheet is pre-oxidized by electrochemical method, the expanded part is intercepted, rinsed with deionized water, dried for 8 hours at 80°C, pulverized, sieved with 60 mesh, and the obtained large sheet is reserved for later use;

[0029] (2) Under ice bath, in a 1000mL three-neck flask, add 140mL concentrated H 2 SO 4 Then under magnetic stirring, 3g of pre-oxidized flake graphite powder, then add 2g NaNO 3 , slowly add 15g KMnO 4 , ensure that the reaction temperature is within 0-10°C, and the reaction is carried out for 0.5 hours;

[0030] (3) Stir for 0.5 hours in a water bath at 40°C; raise the temperature to 97°C, and while stirring, quickly add 500mL of deionized water and react for 0.5 hours;

[0031] (4) Take a 2000mL beaker, pour the reactant from the three-necked flask into the beaker, add deionized water to 2000mL under magnetic stirring, then slowly add 15mL H 2 o 2 (30%H 2 o 2 );

[003...

Embodiment 2

[0040] Graphene oxide was synthesized according to the steps in Example 1.

[0041] Preparation of graphene / PA11 composites:

[0042] (1) Weigh 0.5 parts of graphene oxide concentrate and add 30 parts of water to dilute and disperse, and ultrasonically vibrate for 2 hours to obtain graphene oxide dispersion;

[0043] (2) Put the graphene oxide dispersion and 99.5 parts of PA11 monomer into the reaction kettle, heat and mix evenly, pass in nitrogen gas for 3 times, stir for 30 minutes, and the temperature is 90°C;

[0044] (3) Adjust the polymerization pressure by releasing water vapor, raise the temperature to about 190°C for 1-2 hours, keep the polymerization pressure at 1.6-2.5MPa, then raise the temperature to about 260°C for 6-7 hours, keep the polymerization pressure at 1.6-2. 2.8 MPa;

[0045] (4) After the reaction is finished, cool at a rate of 0.5 to 0.7°C / min, and when the temperature drops to 90 to 110°C, cool at a rate of 3 to 5°C / min until cooled to room tempera...

Embodiment 3

[0048] Graphene oxide was synthesized according to the steps in Example 1.

[0049] Preparation of graphene / PA12 composite:

[0050] (1) Weigh 0.5 part of graphene oxide concentrated solution and add 30 parts of water, and ultrasonically vibrate for 2 hours to obtain graphene oxide dispersion;

[0051] (2) Put the graphene oxide dispersion and 99.5 parts of PA12 monomer into the reaction kettle, heat and mix evenly, pass in nitrogen for 3 times, stir for 30 minutes, and the temperature is 90°C;

[0052] (3) Adjust the polymerization pressure by releasing water vapor, raise the temperature to about 190°C for 1-2 hours, keep the polymerization pressure at 1.6-2.5MPa, then raise the temperature to about 260°C for 6-7 hours, keep the polymerization pressure at 1.6-2. 2.8 MPa;

[0053] (4) After the reaction is finished, cool at a rate of 0.5 to 0.7°C / min, and when the temperature drops to 90 to 110°C, cool at a rate of 3 to 5°C / min until cooled to room temperature; release the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com