High thermal-conductivity polymer composite material and preparation method thereof

A composite material and polymer technology, which is applied in the field of high thermal conductivity polymer composite materials and their preparation, can solve the problems of affecting the application effect of ceramic filler nanoparticles, easy aggregation and agglomeration, and high surface energy, and achieves that the preparation method is easy to operate, The effect of strong controllability and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

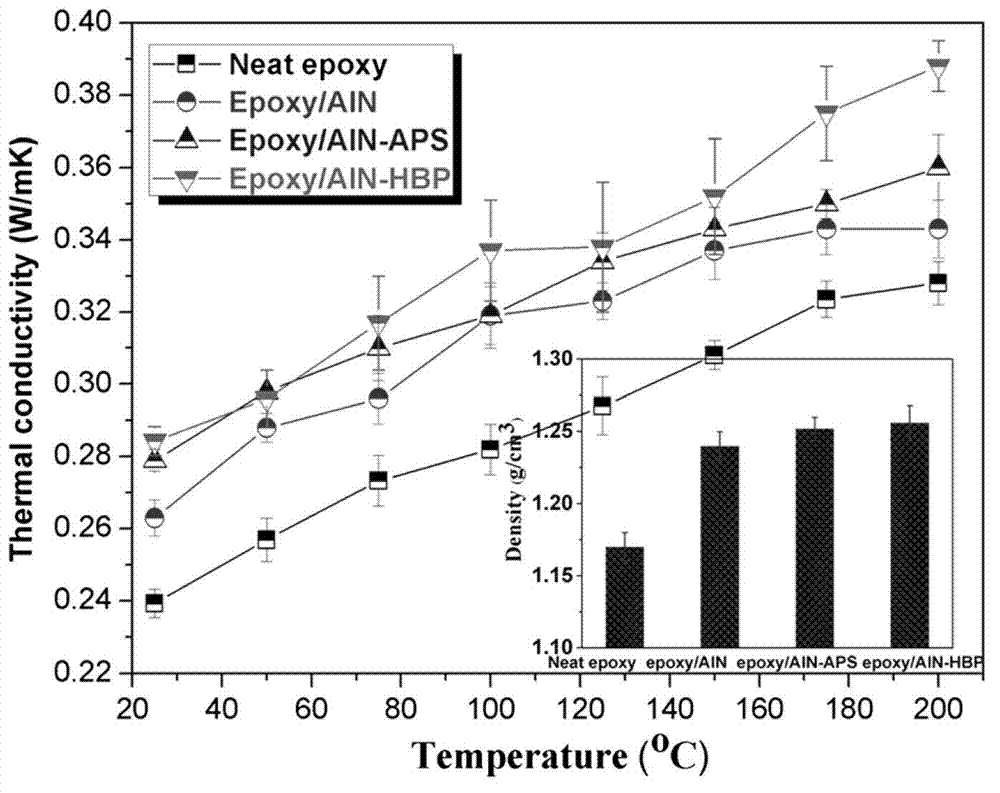

[0032] The preparation method of the highly thermally conductive functionalized ceramic thermally conductive filler / epoxy resin polymer composite material of the present invention mainly includes the following two steps:

[0033] (1) Disperse amino-functionalized ceramic thermally conductive filler nanoparticles in a solvent, add quantitative 3,5-diaminobenzoic acid, pyridine and triphenyl phosphite, react at 100°C for 3 hours under a nitrogen atmosphere, and filter , washing, and drying to obtain hyperbranched polyaramid-grafted ceramic-type heat-conducting filler nanoparticles;

[0034] (2) Add an appropriate amount of aluminum acetylacetonate to the epoxy resin, stir and dissolve at 80°C, cool to room temperature after vacuum degassing, and at the same time disperse the hyperbranched polyaramid-grafted ceramic-type thermally conductive filler nanoparticles into the acetone solvent Medium, ultrasonic 30min. Then the hyperbranched polyaramid grafted ceramic thermal filler na...

Embodiment 1

[0038] The preparation method of the high thermal conductivity functionalized aluminum nitride / epoxy resin polymer composite material in this embodiment is as follows:

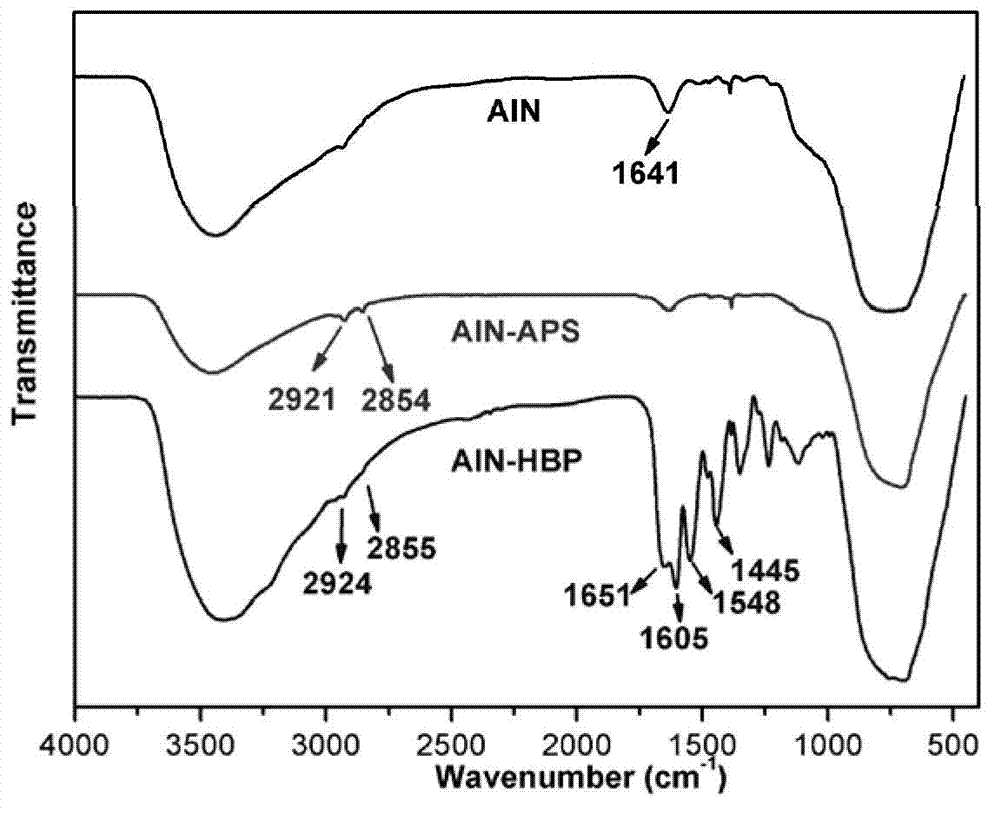

[0039] Pretreatment: Disperse 1g of aluminum nitride nanoparticles in 200ml of xylene and add 0.1g of aminosilane, then reflux at 100°C for 12h, filter, wash with water, and dry to obtain amino-functionalized aluminum nitride nanoparticles.

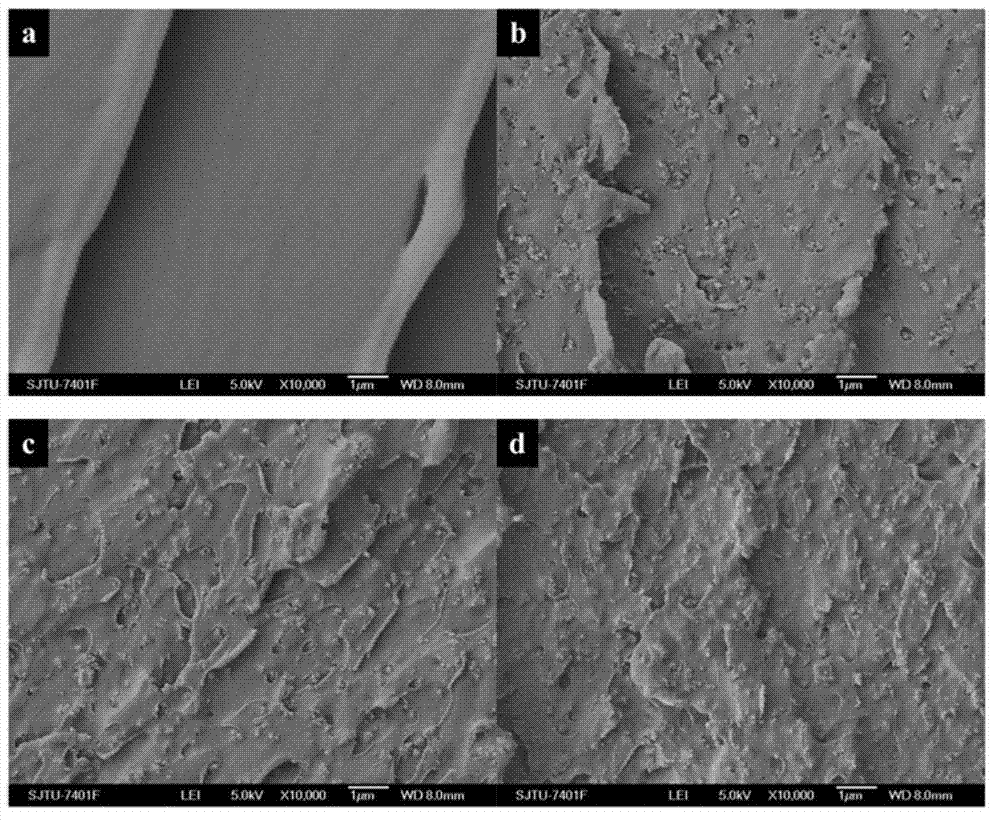

[0040] (1) Disperse 0.65g of 3,5-diaminobenzoic acid, 6.5g of amino-functionalized aluminum nitride nanoparticles, 6ml of pyridine and 6ml of triphenyl phosphite in 200ml of N-methylpyrrolidone solution, at 100°C Reaction under nitrogen atmosphere for 3 hours, after filtration, repeated washing with methanol and suction filtration, and then vacuum drying at 60°C to obtain hyperbranched polyaramid grafted aluminum nitride (AlN-HBP);

[0041](2) Add 0.3g of aluminum acetylacetonate to 30g of epoxy resin, stir and dissolve at 80°C, and cool to room temperature after vacuum d...

Embodiment 2

[0048] The preparation method of the high thermal conductivity functionalized boron nitride / epoxy resin polymer composite material in this embodiment is as follows:

[0049] Pretreatment: Disperse 1g of boron nitride nanoparticles in 200ml of xylene and add 0.1g of aminosilane, then reflux at 100°C for 12h, filter, wash with water, and dry to obtain amino-functionalized boron nitride nanoparticles.

[0050] (1) Disperse 0.65g of 3,5-diaminobenzoic acid, 6.5g of amino-functionalized boron nitride nanoparticles, 6ml of pyridine and 6ml of triphenyl phosphite in 200ml of N-methylpyrrolidone solution, at 100°C Reaction under nitrogen atmosphere for 3 hours, after filtration, repeated washing with methanol and suction filtration, then vacuum drying at 60°C to obtain hyperbranched polyarylamide grafted boron nitride (BN-HBP);

[0051] (2) Add 0.3g of aluminum acetylacetonate to 30g of epoxy resin, stir and dissolve at 80°C, degas in vacuum and cool to room temperature, meanwhile dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com