Liquid crystal display panel and liquid crystal display

A liquid crystal display panel and liquid crystal layer technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of large edge distance difference, uneven cell thickness, and inability to eliminate uneven cell thickness, so as to improve uniformity, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

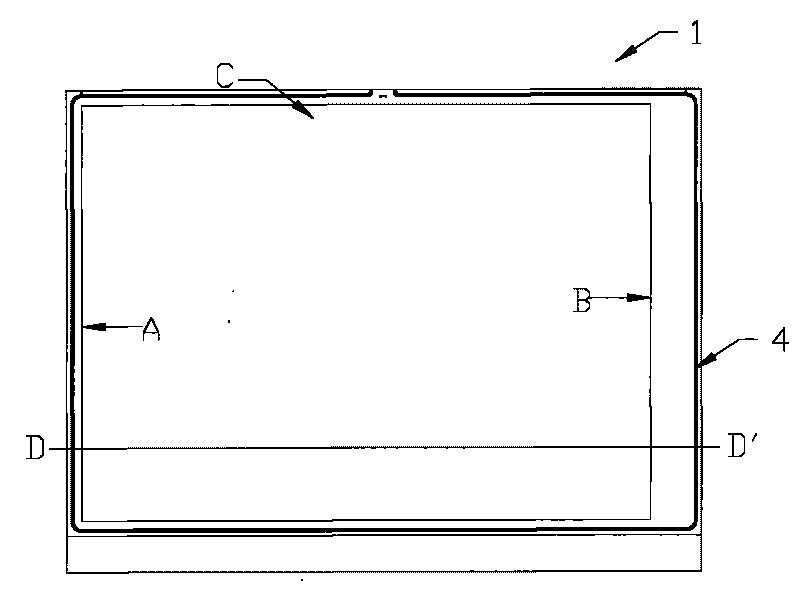

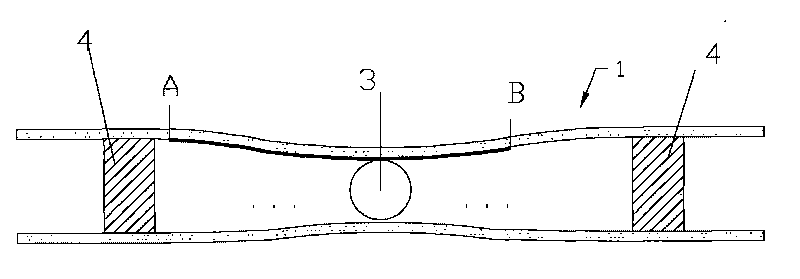

[0040] Figure 4 It is a schematic diagram of a liquid crystal display panel in this embodiment, Figure 5 for Figure 4 The cross-sectional view along the E-E' direction.

[0041] As shown in the figure, the liquid crystal display panel 10 includes: a first substrate 101, a second substrate 110, a liquid crystal layer (not shown in the figure) sandwiched between the two substrates, and a main bezel sealing the liquid crystal layer. 104 , the main frame glue 104 is basically arranged along the edge of the liquid crystal display panel 10 . In this embodiment, the liquid crystal display panel 10 is rectangular, and its display area C is also rectangular. Correspondingly, the main frame glue 104 is basically arranged along the rectangular edge of the liquid crystal display panel.

[0042] A plurality of spacers 103 are located in the display area C between the first substrate 101 and the second substrate 110 to maintain the distance between the two substrates. The first subst...

Embodiment 2

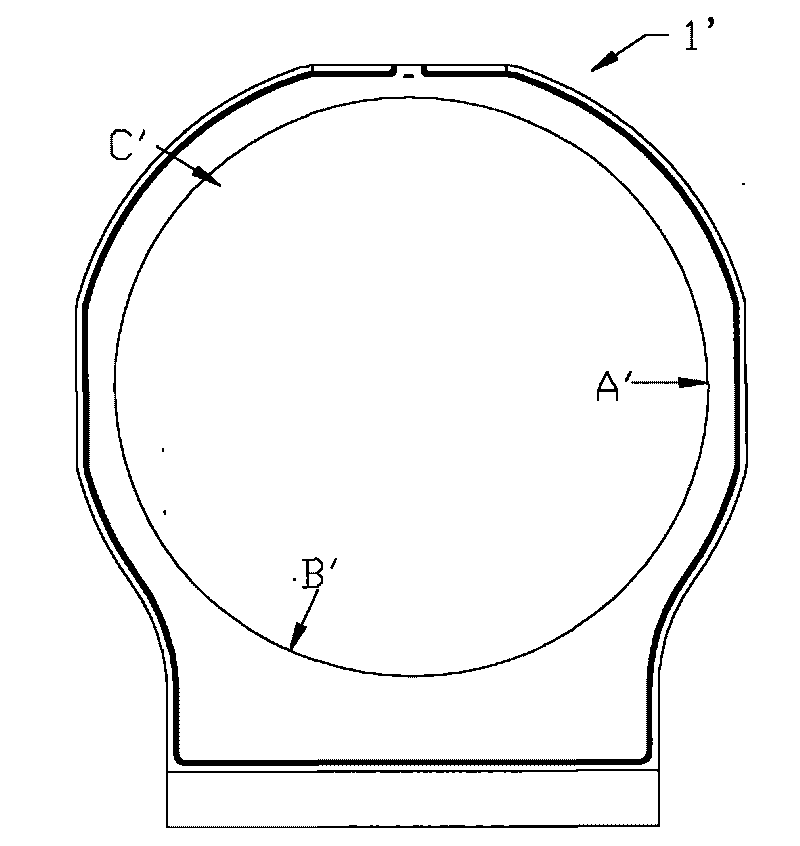

[0051] Image 6 It is a schematic diagram of the liquid crystal display panel in this embodiment. As shown in the figure, the liquid crystal display panel 20 is irregularly circular, including a circular area and a strip-shaped area integrated with the circular area. The display area of the panel is circular, and its center is aligned with the liquid crystal display. The circular regions of the panels substantially coincide.

[0052] Same as the first embodiment, the main bezel glue 204 is basically arranged along the edge of the liquid crystal display panel 20 . However, in this embodiment, the liquid crystal display panel 20 is irregularly circular, and correspondingly, the main bezel glue 204 is basically also irregularly circular.

[0053] The main bezel 204 includes at least three subsections: a first subsection 204a, a second subsection 204b, and a third subsection 204c. The display area C of the liquid crystal display panel 20 includes at least three edges, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com