Frame-sealing glue coating method of liquid crystal display panel and liquid crystal display panel

A liquid crystal display panel and frame sealing adhesive technology, which is applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of LCD display effect influence, peripheral defects, etc., to improve display effect, reduce uneven thickness, and uniform box thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

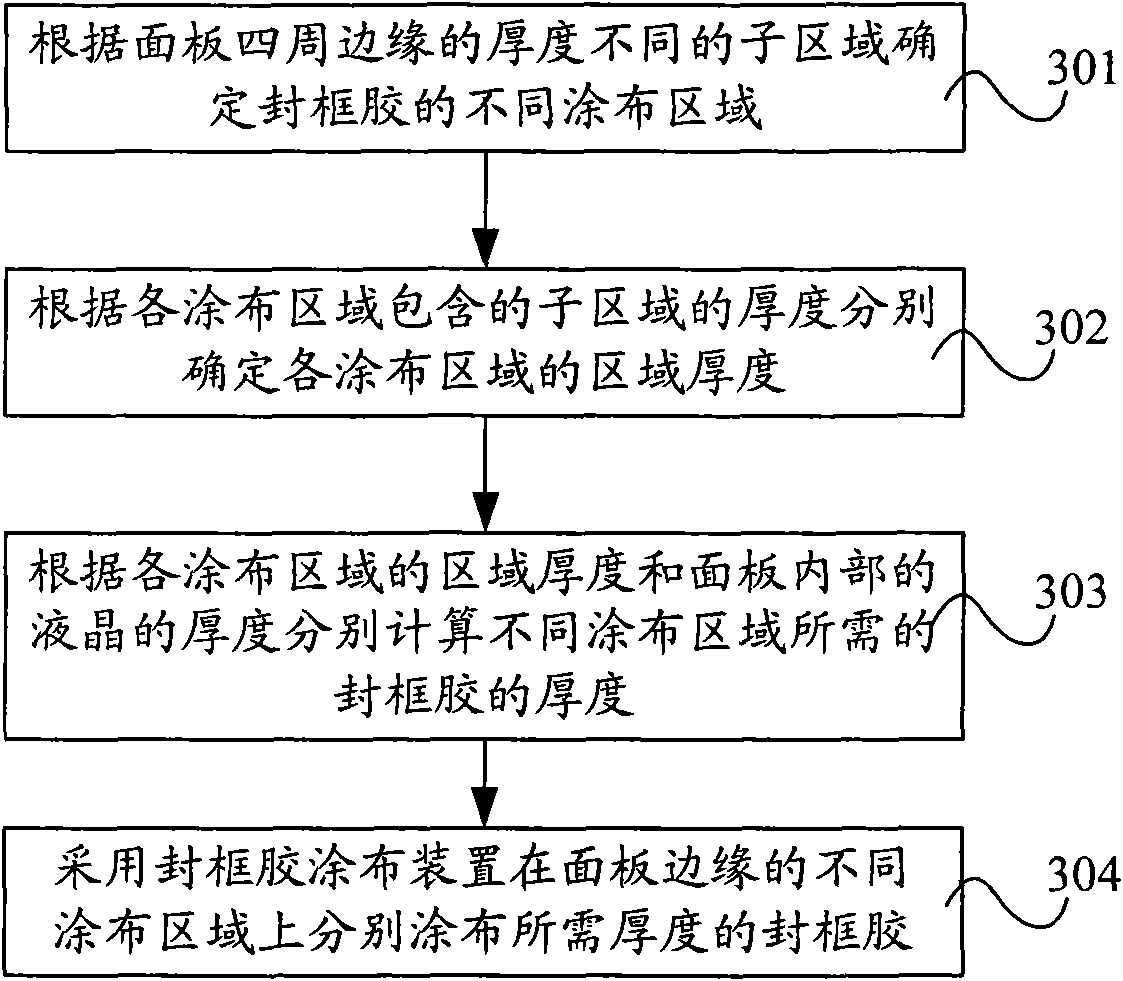

[0023] image 3 It is a flow chart of an embodiment of a sealing glue coating method for a liquid crystal display panel of the present invention, as image 3 As shown, the sealing glue coating method of the liquid crystal display panel provided by the present invention comprises the following steps:

[0024] In step 301 , different coating areas of the frame sealant are determined according to sub-areas with different thicknesses around the edges of the panel.

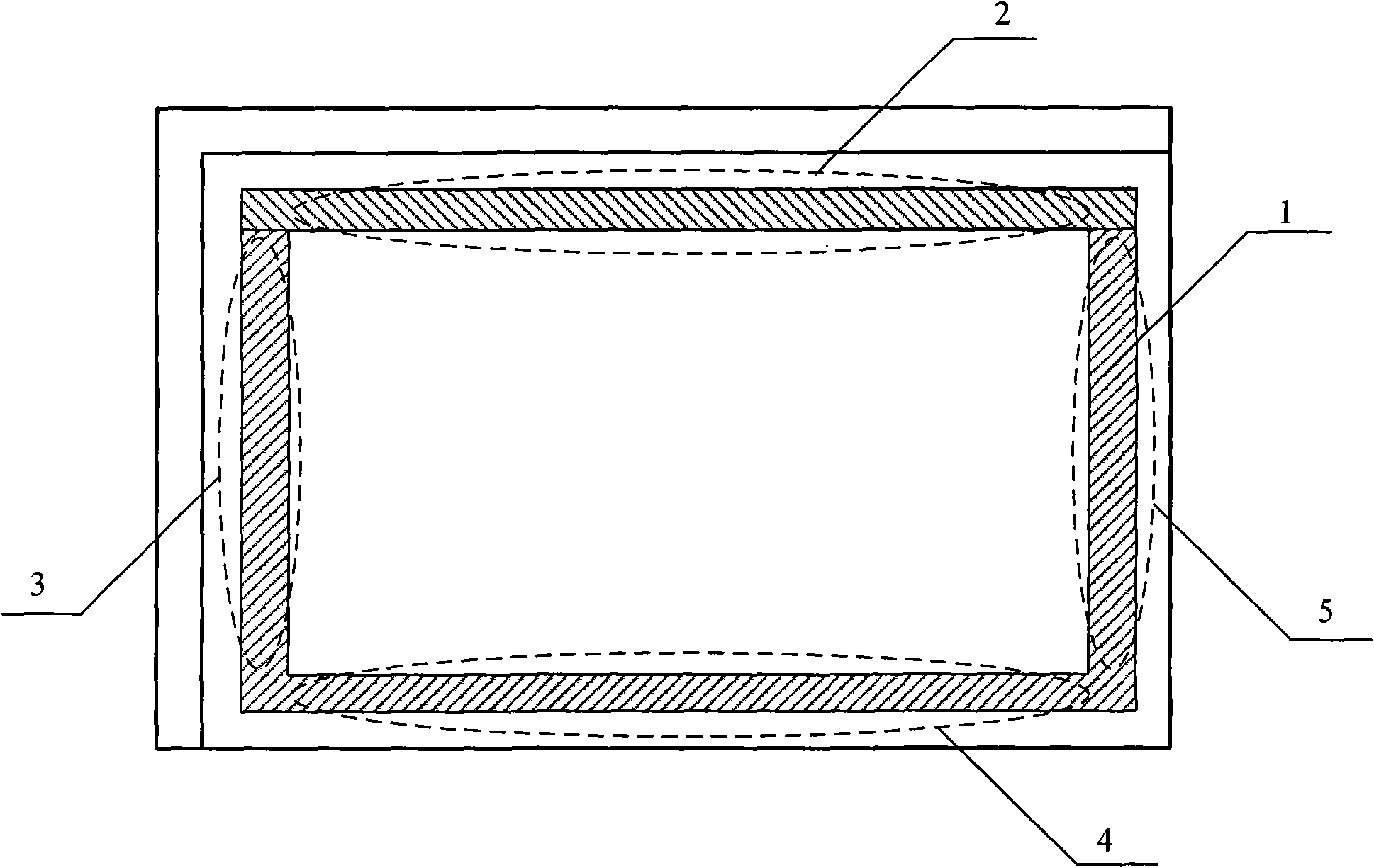

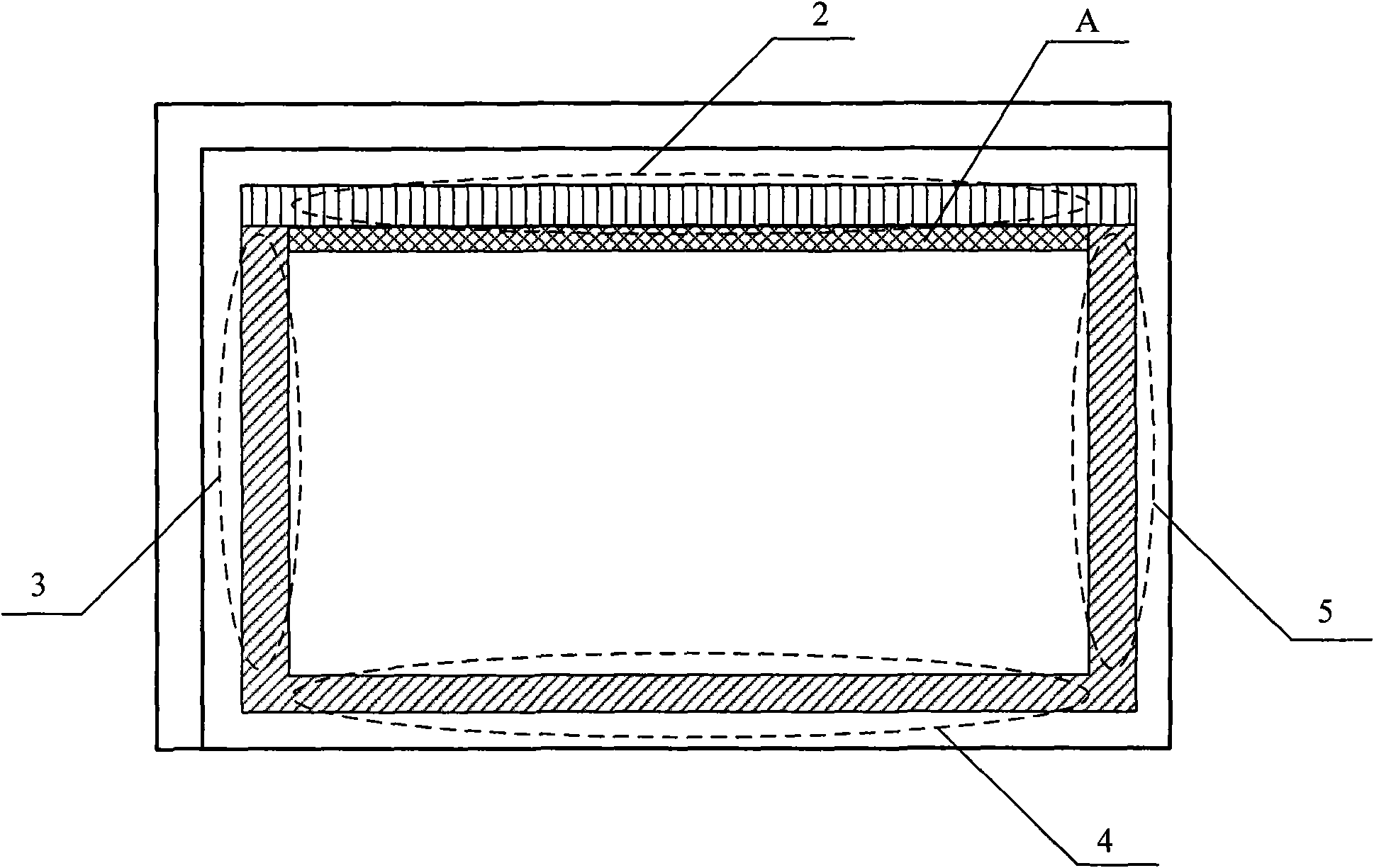

[0025] Another example figure 1 As shown, the position where the sealant 1 is coated is the edge of the LCD panel, and the edge of the LCD panel includes the data (Data) side 2, the gate (Gate) side 3, the data opposite side 4 and the gate opposite side 5, and because The structure of each position in each side is different, and it is composed of various cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com