A kind of photosensitive resin composition and its preparation method and application

A technology of photosensitive resin and resin composition, which is applied in the direction of optomechanical equipment, photosensitive materials used in optomechanical equipment, optics, etc., can solve the problems of PS easy-to-clean elastic recovery, etc., and achieve strong constructability and display performance Excellent, good elastic recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

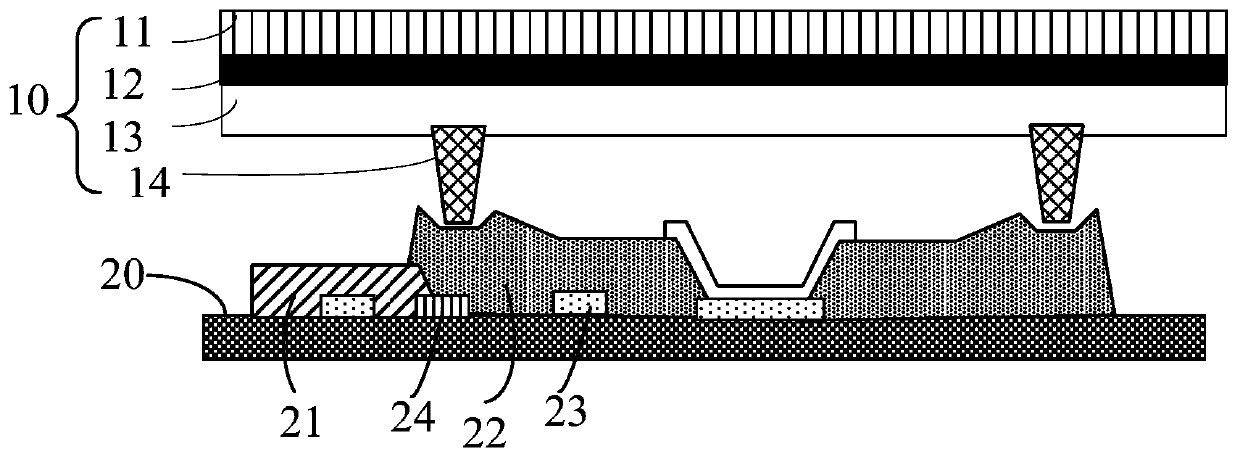

Image

Examples

preparation example Construction

[0092] In the second aspect, the embodiment of the present invention also provides a method for preparing a photosensitive resin composition, comprising the following steps:

[0093] The photopolymerizable monomer, the resin composition, the auxiliary agent, and the photoinitiator are sequentially added into the solvent at a temperature of 60-200° C. and fully stirred to obtain a photosensitive resin composition. The mass percent content of each raw material in the photosensitive resin composition is as above.

[0094] Optionally, the temperature of the solvent is 60-130°C.

[0095] In one embodiment of the present invention, the preparation process of the photosensitive resin composition is as follows:

[0096] A part of the solvent was added into the reaction kettle, nitrogen gas was blown in and the mixture was stirred and heated to 130°C. Next, add the photopolymerizable monomer, resin composition, auxiliary agent, and photoinitiator into the above reaction kettle in seq...

Embodiment 1

[0117] A photosensitive resin composition, comprising the following raw materials in mass percent:

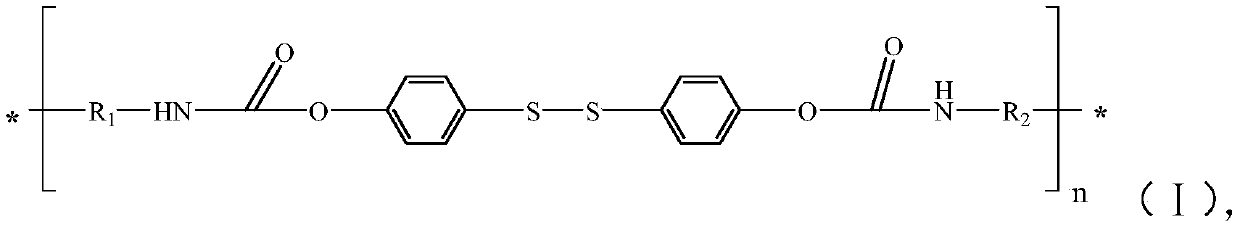

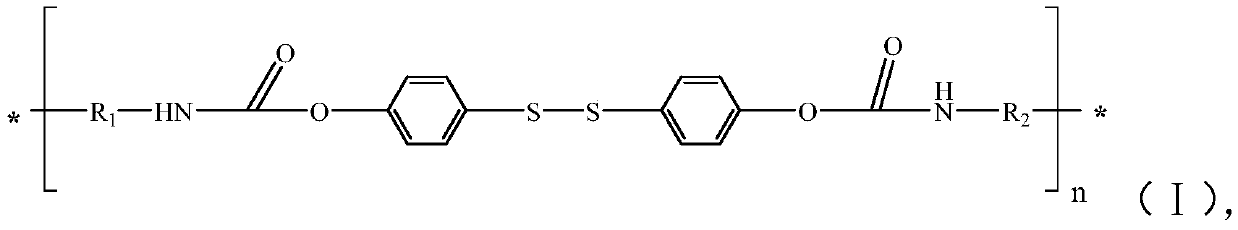

[0118] Modified polyurethane (Mn is 20000, the structural formula is shown in formula (1)): 1.6%;

[0119] Alkali-soluble resin (Mn is 20000, acid value is 32mgKOH / g, its monomer is methacrylic acid): 3%;

[0120] Acrylic resin (its monomer is methyl methacrylate): 1.5%;

[0121] Epoxy acrylate resin (its monomer is glycidyl methacrylate): 1.1%;

[0122] Hydroxyacrylate resin (its monomer is 2-hydroxyethyl methacrylate): 1%;

[0123] Photopolymerizable monomer (3% trimethylolpropane triacrylate and 2.5% pentaerythritol triacrylate) 5.5%;

[0124] Photoinitiators (specifically 0.48% of 2,2-dimethoxy-2-phenylacetophenone and 0.08% of 2-methyl-1-[4-(methylthio)phenyl]-2 -(4-morpholino)-1-propanone) 0.56%;

[0125] Solvent (specifically 62% propylene glycol monomethyl ether acetate, 10% cyclohexanone and 13% ethyl 3-ethoxypropionate): 85%;

[0126] Leveling agent (specificall...

Embodiment 2

[0129] A photosensitive resin composition, comprising the following raw materials in mass percent:

[0130] Modified polyurethane (Mn is 22000, the structural formula is shown in formula (3)): 2%;

[0131] Alkali-soluble resin (Mn is 20000, acid value is 35mgKOH / g, its monomer is α-chloromethacrylic acid): 4%;

[0132] Acrylic resin (its monomer is ethyl methacrylate): 2%;

[0133] Epoxy acrylate resin (its monomer is methacrylate-2,3-epoxypentyl ester): 1.5%;

[0134] Hydroxyacrylate resin (di(meth)acrylate whose monomer is 2-hydroxy-2-ethyl-1,3-propanediol): 1.8%;

[0135] Photopolymerizable monomer (specifically 4% of pentaerythritol triacrylate and 4% of dipentaerythritol pentamethacrylate) 8%;

[0136] Photoinitiator (specifically benzimidazole): 1.2%;

[0137] Solvent (60% propylene glycol monomethyl ether acetate and 15% methoxybutyl acetate) 75%;

[0138] Leveling agent (specifically BYK 306): 0.5%;

[0139] Adhesion promoter (specifically aminopropyltrimethoxysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com