Mother board of liquid crystal panel and manufacturing method thereof

A technology for liquid crystal panels and motherboards, applied in nonlinear optics, static indicators, optics, etc., can solve the problems of abnormal liquid crystal orientation, uneven cell thickness, affecting the picture quality of liquid crystal panels, and achieve uniform cell thickness and good flatness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

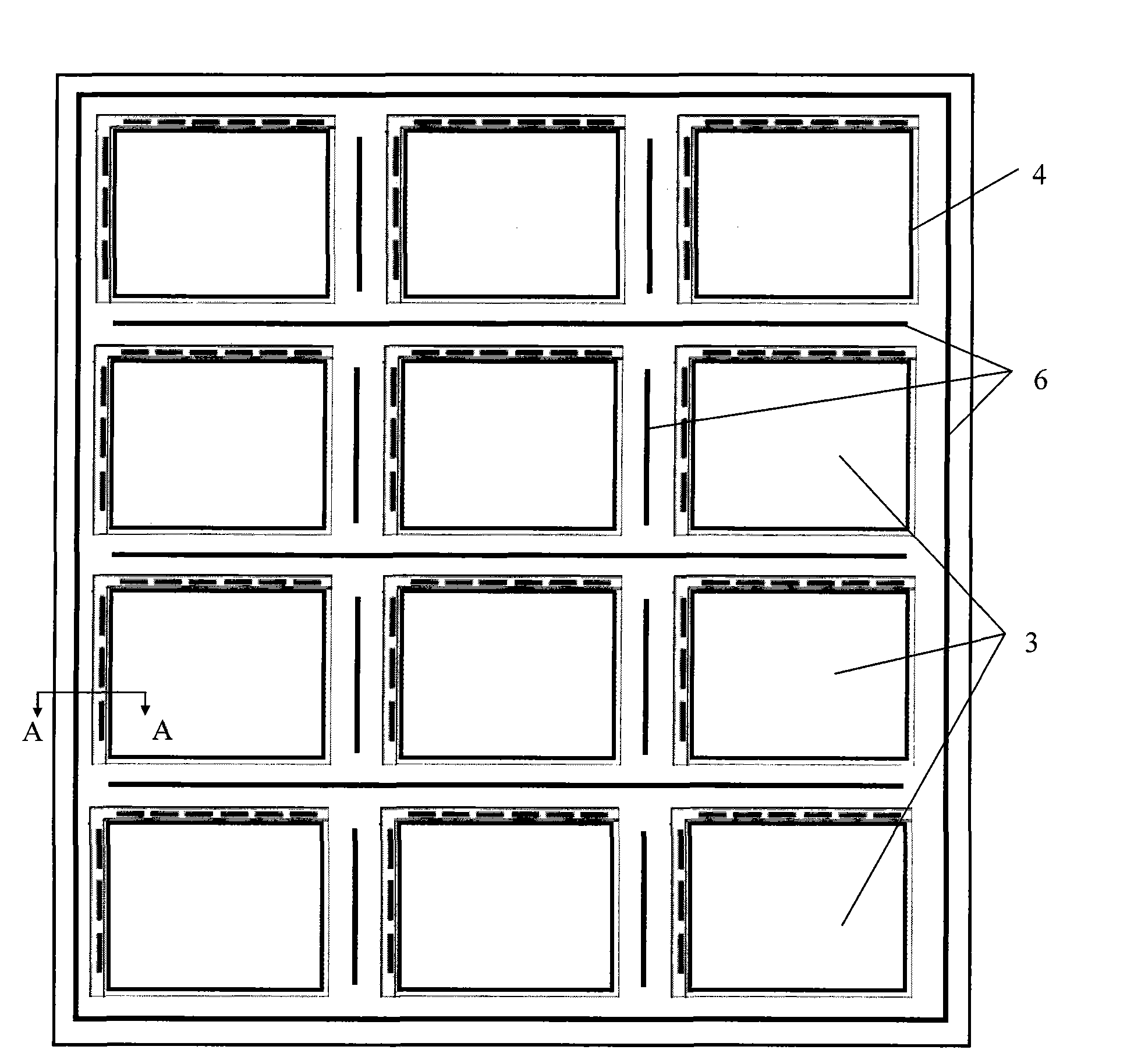

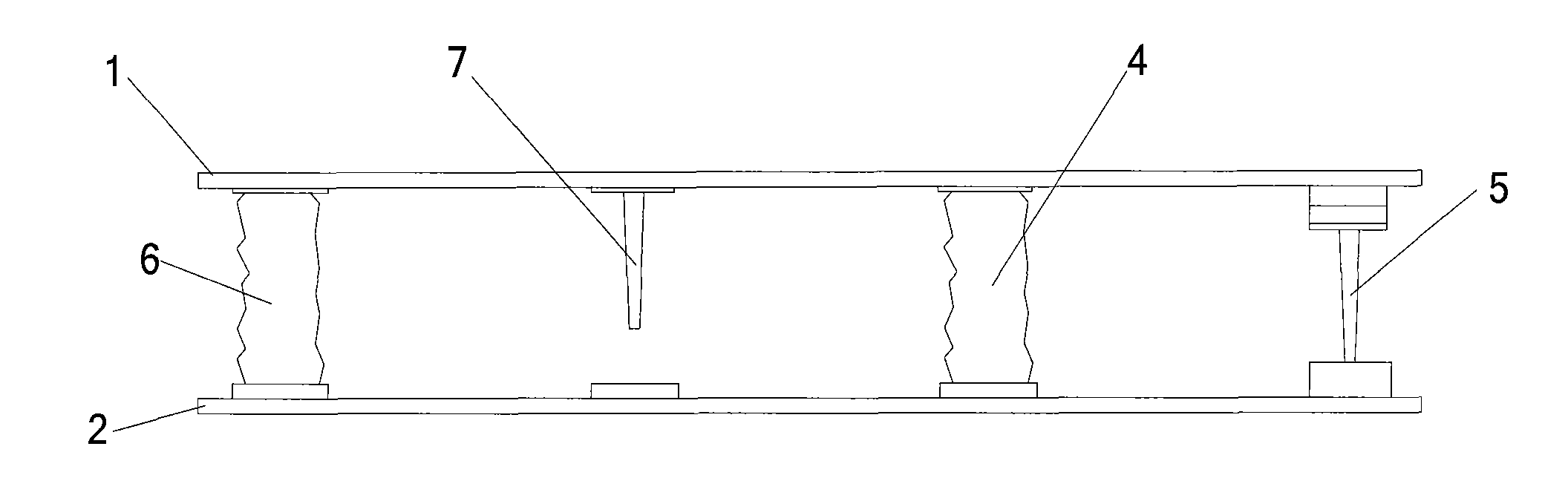

[0032] to combine Figure 4 and Figure 5 As shown, in the liquid crystal panel mother board provided in this embodiment, the auxiliary spacers formed between the main sealant 4 and the auxiliary sealant 6 are all columnar spacers 71, the bottom of which is deposited on the color On the film substrate 1 , the top end is supported on the array substrate 2 .

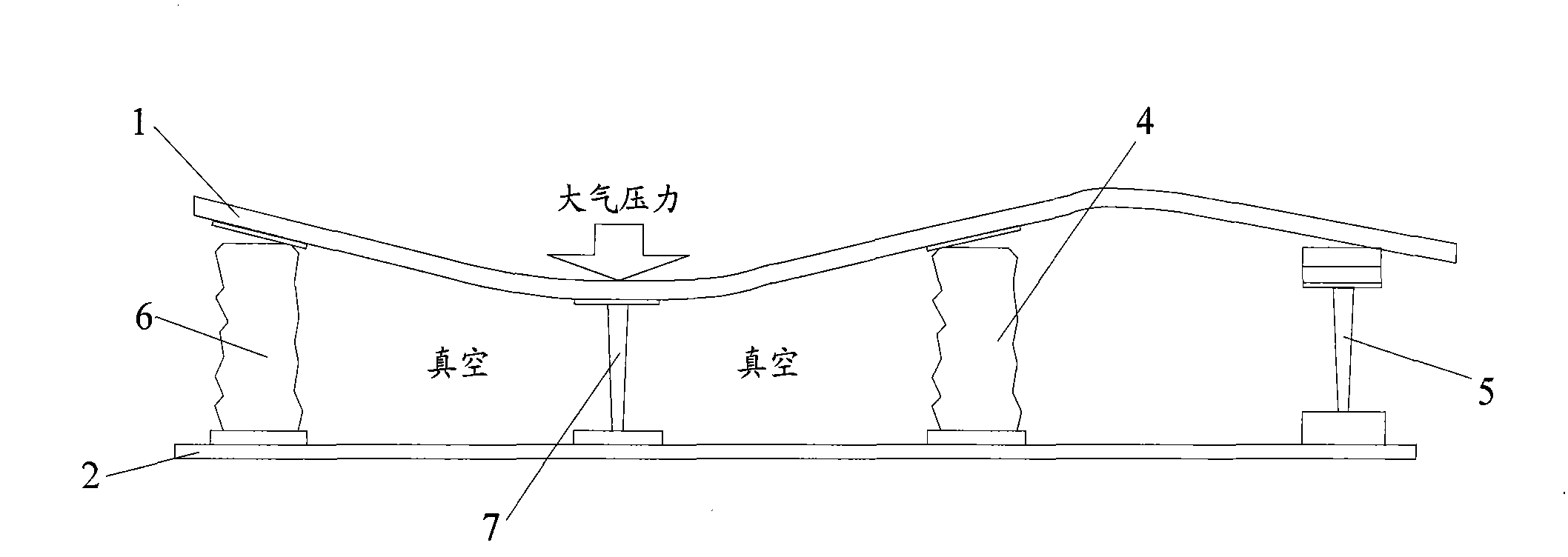

[0033]In addition, in this embodiment, the bottom area of the auxiliary spacer 71 is greater than the bottom area of the main spacer 5, and / or, the distribution density of the auxiliary spacer 71 is greater than the distribution density of the main spacer 5; Inside the area surrounded by the main sealant 4, that is, in the area of a single panel, in addition to the main spacer 5 that maintains the distance between the two substrates, the liquid crystal filled therein can also play a certain role in maintaining the distance between the two substrates. Such a structure increases the contact area between the auxiliary...

Embodiment 2

[0036] combine Figure 4 and Figure 6 As shown, in the motherboard of the liquid crystal panel provided in this embodiment, the auxiliary spacer formed between the main sealant 4 and the auxiliary sealant 6 is a strip wall spacer 72, Its bottom is deposited on the color filter substrate 1 , and its top is supported on the array substrate 2 .

[0037] In some cases, it is necessary to set an opening on the auxiliary sealant 6 so that when the color filter substrate and the array substrate are boxed together, the atmosphere can enter the redundancy of the motherboard of the liquid crystal panel through the opening on the auxiliary sealant 6. In the remaining area, the air pressure inside and outside the substrate located in the redundant area is the same at this time, coupled with the supporting effect of the long wall-shaped spacer 72 arranged in the redundant area, the thickness of the box in the peripheral area of a single panel remains uniform; and, The auxiliary spacer...

Embodiment 3

[0041] Corresponding to the above liquid crystal panel motherboard, in an embodiment of the present invention, a method for manufacturing a liquid crystal panel motherboard is also provided, including:

[0042] A spacer material is deposited on the substrate, followed by a mask exposure process in which the auxiliary spacer area is not exposed, the main spacer area is half-exposed, and the other areas are fully exposed, thereby forming a layer with a height difference on the substrate. Auxiliary spacers and main spacers.

[0043] Specifically, as Figure 7 As shown, the above-mentioned process of making a liquid crystal panel motherboard can be further refined as:

[0044] S1. Depositing a spacer material on the substrate.

[0045] A spacer material layer is formed on the color filter substrate or the array substrate by a CVD (Chemical Vapor Deposition, chemical vapor deposition) process, and the spacer material is photoresist.

[0046] Since the height of the main spacer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com