Porous nitrogen-doped carbon/carbon nanotube composite material, preparation method thereof and application

A technology of nitrogen-doped carbon and composite materials, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of high cost, complicated preparation process, unfavorable commercial application, etc., and achieve low cost and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

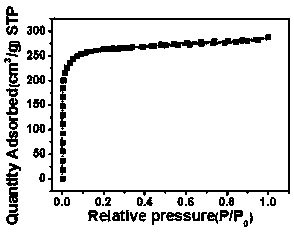

[0032] Weigh 2000 parts of FeCl 3 ·6H 2 O and 300 parts of methyl orange dissolve 160 parts of H 2 O, then added 0.7 parts of pyrrole monomer, reacted for 24 h, filtered, washed and dried to obtain polypyrrole nanotubes. Weigh 900 parts of Zn(NO 3 ) 2 ·6H 2 O dissolved in 30 parts H 2 O, add 150 parts of polypyrrole nanotubes and 100 parts of PVP, and ultrasonically disperse for 30 min to obtain mixed solution A; weigh 2000 parts of 2-methylimidazole and dissolve in 30 parts of H 2 O, then slowly add this solution into solution A, stir magnetically for 2 h, filter, wash and dry to obtain polypyrrole nanotubes / ZIF-8; transfer polypyrrole nanotubes / ZIF-8 to a ceramic crucible, place Tube Furnace, in N 2 Under protection, carbonize at 700 °C for 3 h; soak the obtained carbon material in 1 M HCl solution for 10 h, filter, and obtain porous nitrogen-doped carbon / carbon nanotube composites. The specific surface area of the material is 527 m 2 g -1 . After testing, the c...

Embodiment 2

[0034] Weigh 2800 parts of FeCl 3 ·6H 2 O and 350 parts methyl orange dissolve 150 parts H 2 O, then add 0.5 parts of pyrrole monomer, react for 12 h, filter, wash and dry to obtain polypyrrole nanotubes. Weigh 800 parts of Zn(NO 3 ) 2 ·6H 2 O dissolved in 30 parts H 2 O, add 100 parts of polypyrrole nanotubes and 100 parts of PVP, and ultrasonically disperse for 60 min to obtain mixed solution A; weigh 2000 parts of 2-methylimidazole and dissolve in 30 parts of H 2 O, then slowly add the solution to solution A, stir magnetically for 4 h, filter, wash and dry to obtain polypyrrole nanotubes / ZIF-8; transfer polypyrrole nanotubes / ZIF-8 to a ceramic crucible, place Tube Furnace, in N 2 Under protection, carbonize at 800 °C for 2 h; soak the obtained carbon material in 3 M HCl solution for 12 h, filter, and obtain porous nitrogen-doped carbon / carbon nanotube composites.

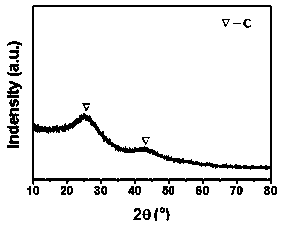

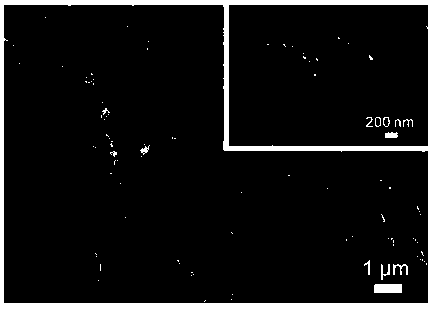

[0035] SEM images show that the material forms a composite structure of porous carbon particles wrappe...

Embodiment 3

[0037] Weigh 3000 parts FeCl 3·6H 2 O and 250 parts of methyl orange were dissolved in 200 mL of H 2 O, then add 1 part of pyrrole monomer, react for 12 h, filter, wash and dry to obtain polypyrrole nanotubes. Weigh 800 parts of Zn(NO 3 ) 2 ·6H 2 O dissolved in 00 parts H 2 O, add 50 parts of polypyrrole nanotubes and 100 parts of PVP, and ultrasonically disperse for 30 min to obtain mixed solution A; weigh 2500 parts of 2-methylimidazole and dissolve in 30 parts of H 2 O, then slowly add the solution to solution A, stir magnetically for 12 h, filter, wash and dry to obtain polypyrrole nanotubes / ZIF-8; transfer polypyrrole nanotubes / ZIF-8 to a ceramic crucible, place For tube furnaces, at N 2 Under protection, carbonize at 900 °C for 1 h; soak the obtained carbon material in 2 M HCl solution for 24 h, filter, and obtain porous nitrogen-doped carbon / carbon nanotube composites.

[0038] The material has a specific surface area of 632 m 2 g -1 . After testing, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com