Laser cladding in-situ synthesis ceramic phase reinforced Fe-base cladding layer and preparation method thereof

A technology of laser cladding and in-situ synthesis, which is applied in the direction of coating and metal material coating process to achieve the effect of simple production equipment and process, convenient operation and easy automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

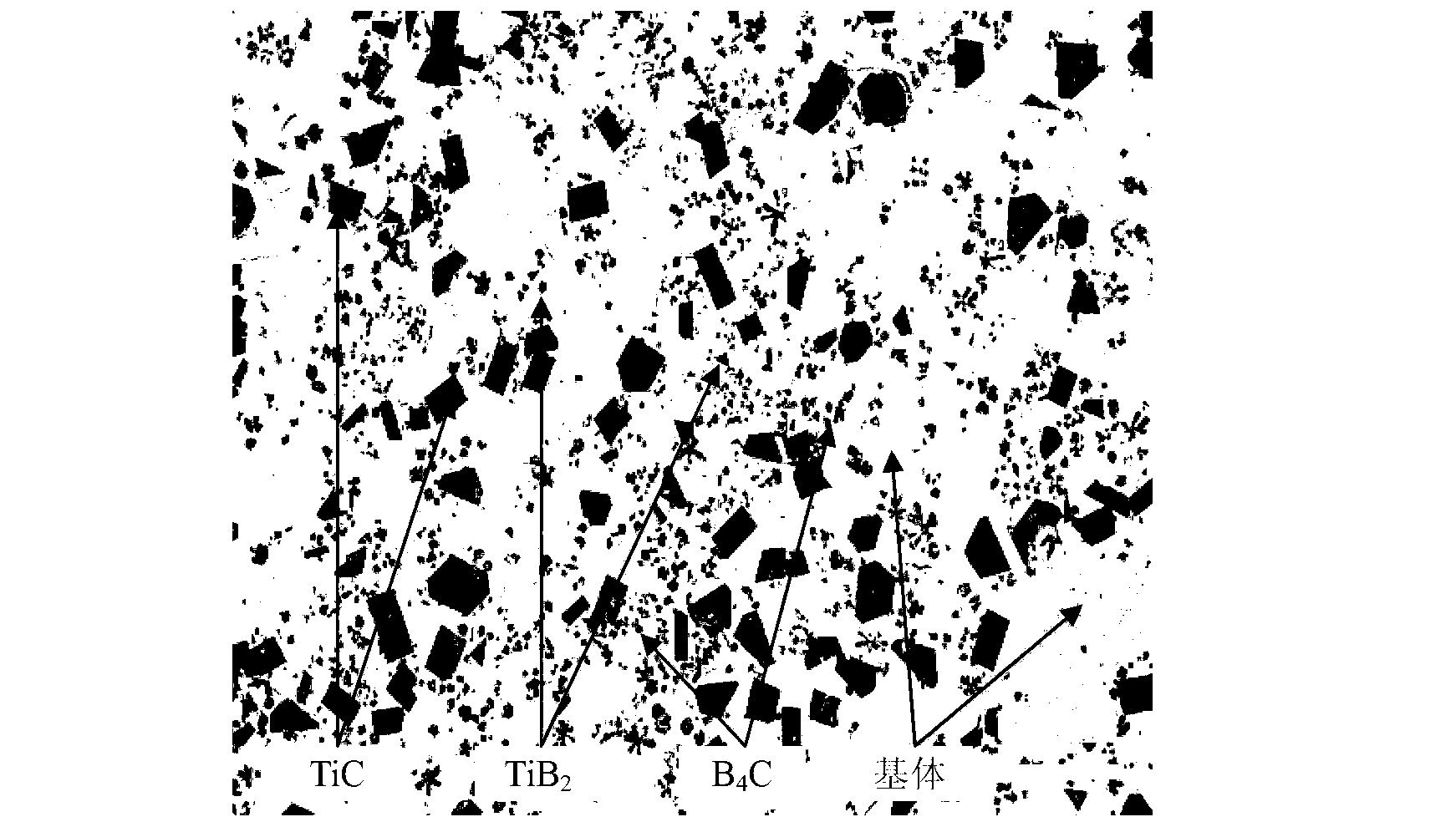

Image

Examples

Embodiment 1

[0021] Laser power 900W, Ti-Fe powder and B 4 C press response B 4 C+3Ti=2TiB 2 +TiC ratio

[0022] (1) Substrate pretreatment

[0023] Degrease and derust the working surface of the processed automobile die steel Cr12MoV substrate, and polish it with sandpaper to obtain a smooth and smooth surface;

[0024] (2) Laser cladding

[0025] In the composition ratio of the preset coating material, the percentages of the elements in the total material of the ferroboron powder, ferrosilicon powder, ferrochrome powder and iron powder accounting for the total weight of the four alloy powder materials are: B1.3%, Si1.2%, Cr11.3%, C0.1%, the balance Fe; and Ti30wt% titanium iron powder and B 4 The percentages of C powder in the total weight of all alloy powder materials are: 22.5% of Ti-Fe powder containing 30% Ti, B 4 C powder 2.5%; powder particle size is 80-120 mesh. After mixing the powder, mix it evenly and dry it. Adjust the laser cladding process parameters under the protect...

Embodiment 2

[0027] Laser power: 1200W, Ti-Fe powder and B 4 C press response B 4 C+3Ti=2TiB 2 +TiC ratio

[0028] (1) Substrate pretreatment

[0029] Degrease and derust the working surface of the processed automobile die steel Cr12MoV substrate, and polish it with sandpaper to obtain a smooth and smooth surface;

[0030] (2) Laser cladding

[0031] In the composition ratio of the preset coating material, the percentages of the elements in the total material of the ferroboron powder, ferrosilicon powder, ferrochrome powder and iron powder accounting for the total weight of the four alloy powder materials are: B1.3%, Si1.2%, Cr11.3%, C0.09%, balance Fe. And the ferrotitanium powder containing Ti29.1wt% and B 4 The percentages of C powder in the total weight of all alloy powder materials are: Ti-Fe powder 22.5% containing Ti29.1%, B 4 C powder 2.5%; powder particle size is 80-120 mesh. After mixing the powder, mix it evenly and dry it. Adjust the laser cladding process parameters un...

Embodiment 3

[0033] Laser power: 1500W, Ti-Fe powder and B 4 C press response B4 C+3Ti=2TiB 2 +TiC ratio

[0034] (1) Substrate pretreatment

[0035] Degrease and derust the working surface of the processed automobile die steel Cr12MoV substrate, and polish it with sandpaper to obtain a smooth and smooth surface;

[0036] (2) Laser cladding

[0037] In the composition ratio of the preset coating material, the percentages of the elements in the total material of the ferroboron powder, ferrosilicon powder, ferrochrome powder and iron powder accounting for the total weight of the four alloy powder materials are: B1.3%, Si1.1%, Cr10.7%, C0.12%, the balance Fe; and Ti30.7wt% titanium iron powder and B 4 The percentages of C powder in the total weight of all alloy powder materials are: 26.1% of Ti-Fe powder containing 30.7% Ti, B 4 C powder 2.2%; powder particle size is 80-120 mesh. After mixing the powder, mix it evenly and dry it. Adjust the laser cladding process parameters under the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com