In-situ nanocomposite ceramic-reinforced aluminum alloy powder for 3D printing and preparation method thereof

A composite ceramic and 3D printing technology, applied in the field of additive manufacturing, can solve the problems of reducing the performance of aluminum alloys, consuming more energy, and having more slag, achieving high bulk density, improving overall performance, reducing production cycle and production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In-situ nano-composite ceramic reinforced aluminum alloy powder for 3D printing of the present invention, in-situ nano-Al 2 o 3 with TiB 2 Ceramic particles are uniformly dispersed and reinforced aluminum alloy powder (aluminum alloy powder of Al2O3 phase and TiB2 phase grown on an aluminum alloy substrate in situ), and its preparation method includes the following steps:

[0039] (1) Raw material configuration: B 2 o 3 、TiO 2 The powder and the aluminum alloy block are weighed at a molar mass ratio of 1:1:15;

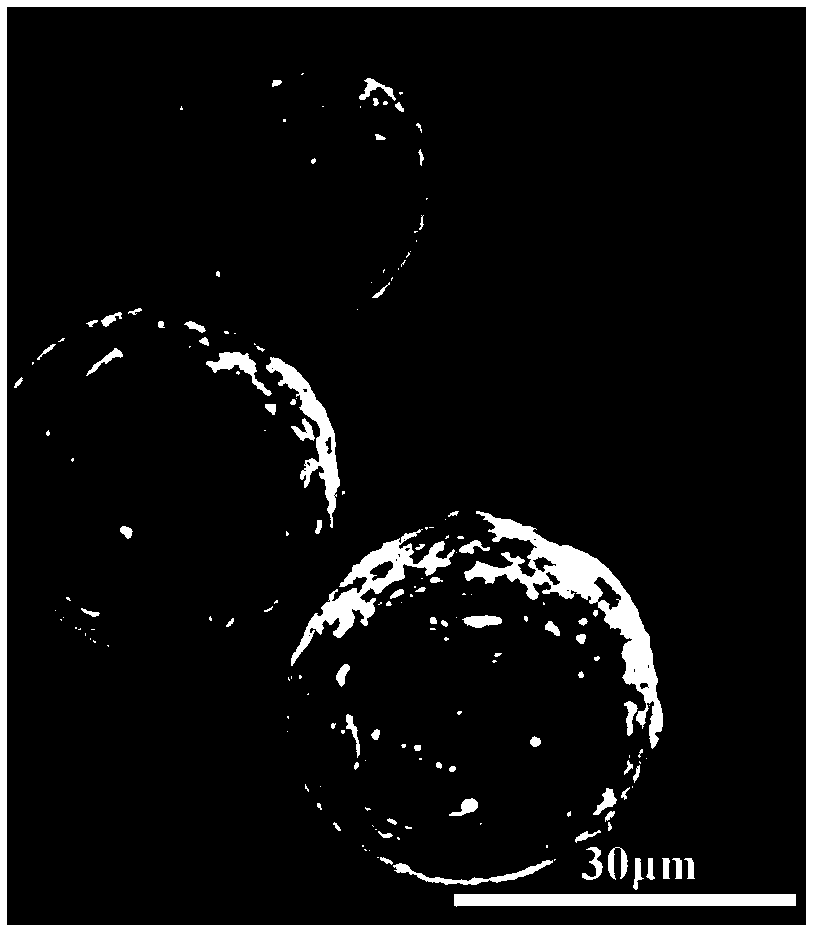

[0040] (2) Induction smelting: Put the weighed aluminum alloy block into the preset vacuum (in this example, the preset vacuum degree is 0.05Pa) frequency induction furnace, and melt it under the protection of filling inert argon , slag removal, the melting temperature is 1200°C, the B 2 o 3 、TiO 2 The oxide powder is added to the aluminum alloy melt, and the electromagnetic stirring is turned on to promote the 3B 2 o 3 +3TiO 2 +10Al→5Al 2 o 3 +3TiB...

Embodiment 2

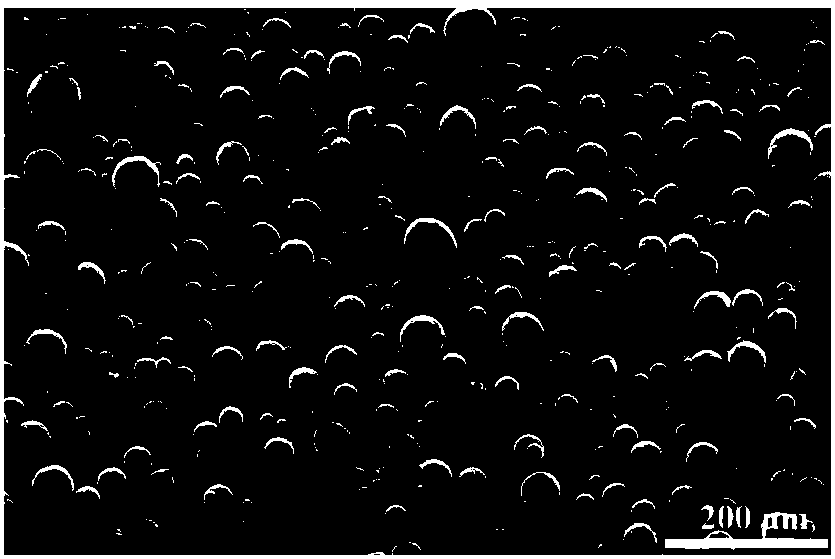

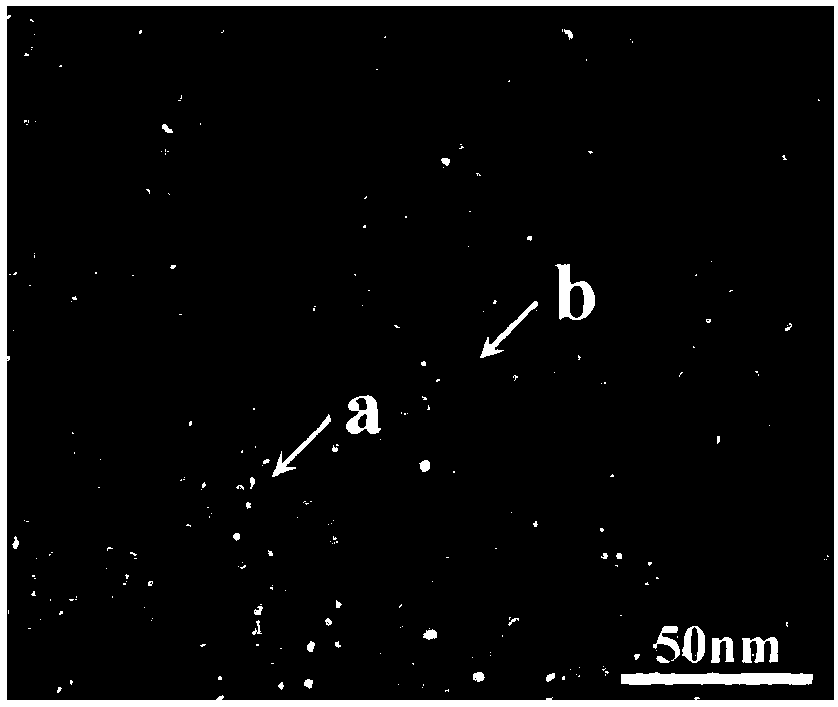

[0044] The difference between this embodiment and specific embodiment 1 is that when the mixture is proportioned in step (1), the B 2 o 3 、TiO 2 The molar mass ratio of the powder to the base aluminum alloy block is controlled at 1:1:25; in step (3), the melt flow rate is set to 1.5Kg / min, and the others are the same as in Embodiment 1, and the obtained Al 2 o 3 Ceramic reinforcement phase and TiB 2 Aluminum alloy powder of ceramic reinforcement phase (as attached Figure 2-3 shown).

Embodiment 3

[0046] The difference between this embodiment and specific embodiment 1 is that in step (2), the melting temperature is controlled at 1600°C; in step (3), the melt flow rate is set to 2 Kg / min, and the others are the same as in specific embodiment 1 Same, get Al 2 o 3 Ceramic reinforcement phase and TiB 2 Aluminum alloy powder of ceramic reinforcement phase (as attached Figure 4 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com