Hydrophobic modification method of nanocellulose

A technology of nanocellulose and hydrophobic modification, applied in the field of hydrophobic modification of nanocellulose, can solve the problems of complicated steps, high preparation cost, harsh conditions, etc., and achieve the effects of simple preparation process, no environmental pollution, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

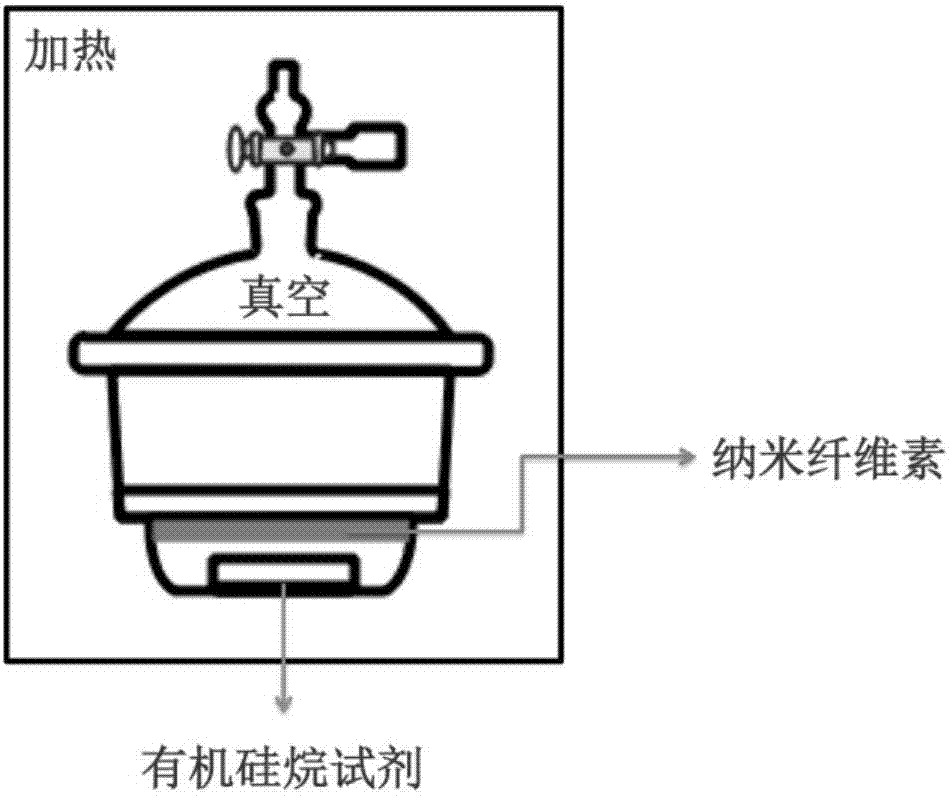

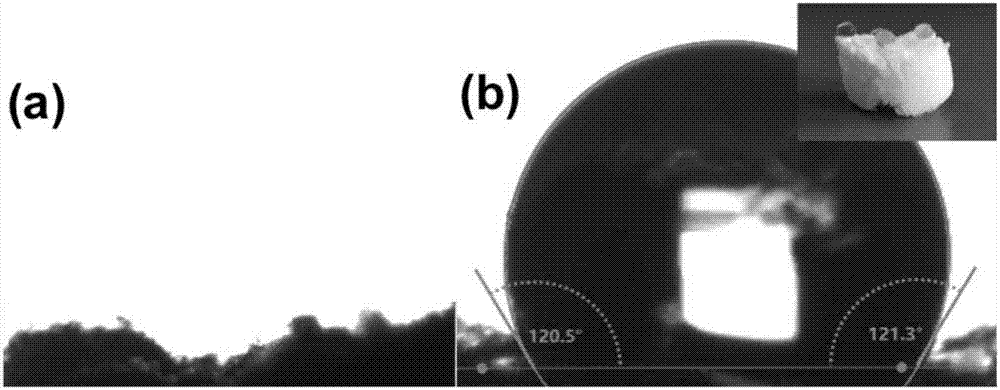

[0026] The cellulose nanocrystals are prepared according to the traditional method of hydrolyzing cellulose with sulfuric acid and dried by a freeze dryer. Place the cellulose nanocrystals in a desiccator, place a small petri dish at the bottom of the desiccator, add 5 mL of hexamethyldisilazane to it, evacuate the desiccator, put it in an oven at 75°C and heat it for 2 hours. Take it out and cool to room temperature to obtain hydrophobic nanocrystalline cellulose with a water / air contact angle of 121°, such as figure 2 Shown. The device according to the invention is figure 1 Shown.

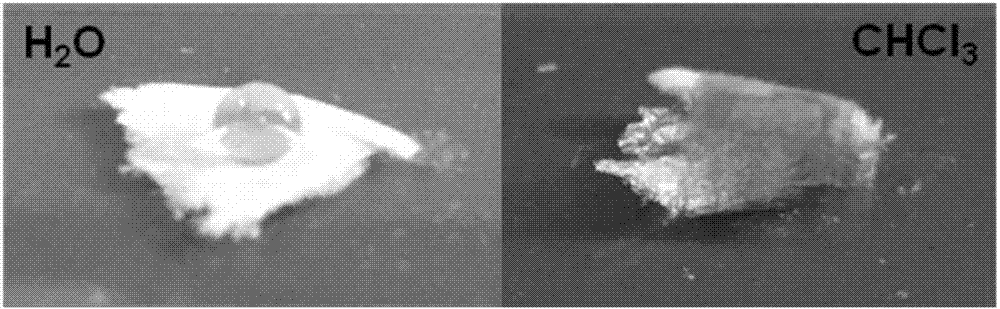

[0027] image 3 This is a photograph of the cellulose nanocrystals prepared in Example 1 of the present invention that selectively absorb water and chloroform. It can be seen from the figure that the modified cellulose nanocrystals have a greatly reduced affinity for water, but have good absorption for organic solvents.

Embodiment 2

[0029] The cellulose nanocrystals are prepared according to the traditional method of hydrolyzing cellulose with sulfuric acid and dried by a freeze dryer. Place the cellulose nanocrystals in a desiccator, place a small petri dish at the bottom of the desiccator, add 5 mL of hexamethyldisilazane to it, evacuate the desiccator, put it in an oven at 75°C and heat it for 2 hours. Take it out and cool to room temperature to obtain a hydrophobic nanocrystalline cellulose aerogel with a water / air contact angle of 125°.

Embodiment 3

[0031] The cellulose nanocrystals are prepared according to the traditional method of hydrolyzing cellulose with sulfuric acid and dried by a freeze dryer. Place the cellulose nanocrystals in a desiccator, place a small petri dish at the bottom of the desiccator, add 5 mL of methyltrimethoxysilane to it, evacuate the desiccator, put it in an oven at 75°C and heat for 2 hours, then take it out Cool to room temperature to obtain hydrophobic nanocrystalline cellulose with a water / air contact angle of 132°, such as Figure 4 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com