Fiber reinforced carbon-silicon carbide ceramic matrix composite material and preparation method thereof

A silicon carbide ceramic-based, fiber-reinforced technology, which is applied in the field of composite material preparation, can solve the problems of affecting the mechanical properties and ablation resistance of C/C-SiC composite materials, and cannot achieve sufficient reaction, so as to improve the mechanical properties and anti-corrosion properties. Excellent ablative properties, excellent anti-ablation properties, and low free silicon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In a first aspect, the present invention provides a method for preparing a fiber-reinforced carbon-silicon carbide ceramic matrix composite material, the method comprising the following steps:

[0027] (1) Prepare one deck pyrolytic carbon layer (PyC layer) and one deck silicon carbide layer (SiC layer) successively on the surface of fiber prefabricated body, make modified fiber prefabricated body; The present invention does not have to adopted fiber prefabricated body For special requirements, for example, it can be a fiber preform with a needle-punched structure, a finely punctured structure or a stitched structure, preferably a needle-punched fiber preform, whose purpose is to serve as the skeleton of the ceramic matrix composite material of the present invention to enhance Toughening effect;

[0028] (2) impregnating the modified fiber preform obtained in step (1) with a resin solution comprising silicon powder (such as ultra-fine spherical silicon powder), phenolic...

Embodiment 1

[0063]A kind of preparation method of C / C-SiC composite material, its concrete steps are:

[0064] ①Put the carbon fiber prefabricated body into the CVI-C furnace, deposit it for 20 hours, and then put the carbon fiber prefabricated body deposited with the pyrolytic carbon layer into the CVI-SiC furnace, deposit it for 50 hours and release it from the furnace. A pyrolytic carbon layer with a thickness of 7 μm and a silicon carbide layer with a thickness of 5 μm were sequentially prepared on the surface of the body to obtain a modified fiber preform.

[0065] ② Vacuum impregnation of the modified fiber preform obtained in step ① using a resin solution containing silicon powder, graphene oxide and aminophenol-formaldehyde resin as an impregnating agent, and then the impregnated modified fiber preform is sequentially subjected to a pressure curing step and 800 ℃ high-temperature pyrolysis step; wherein, the mass ratio of silicon powder, graphene oxide and aminophenol-formaldehyde...

Embodiment 2

[0071] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0072] In ②, the mass ratio of silicon powder, graphene oxide and aminophenol-formaldehyde resin is 7:0.1:10.

[0073] In ③, repeat step ②, the process of vacuum impregnation-pressure curing-800°C high-temperature pyrolysis 3 times until the weight increase rate of the composite material is less than 1.0%, and the obtained density is 2.0g / cm 3 The C / C-Si composite material.

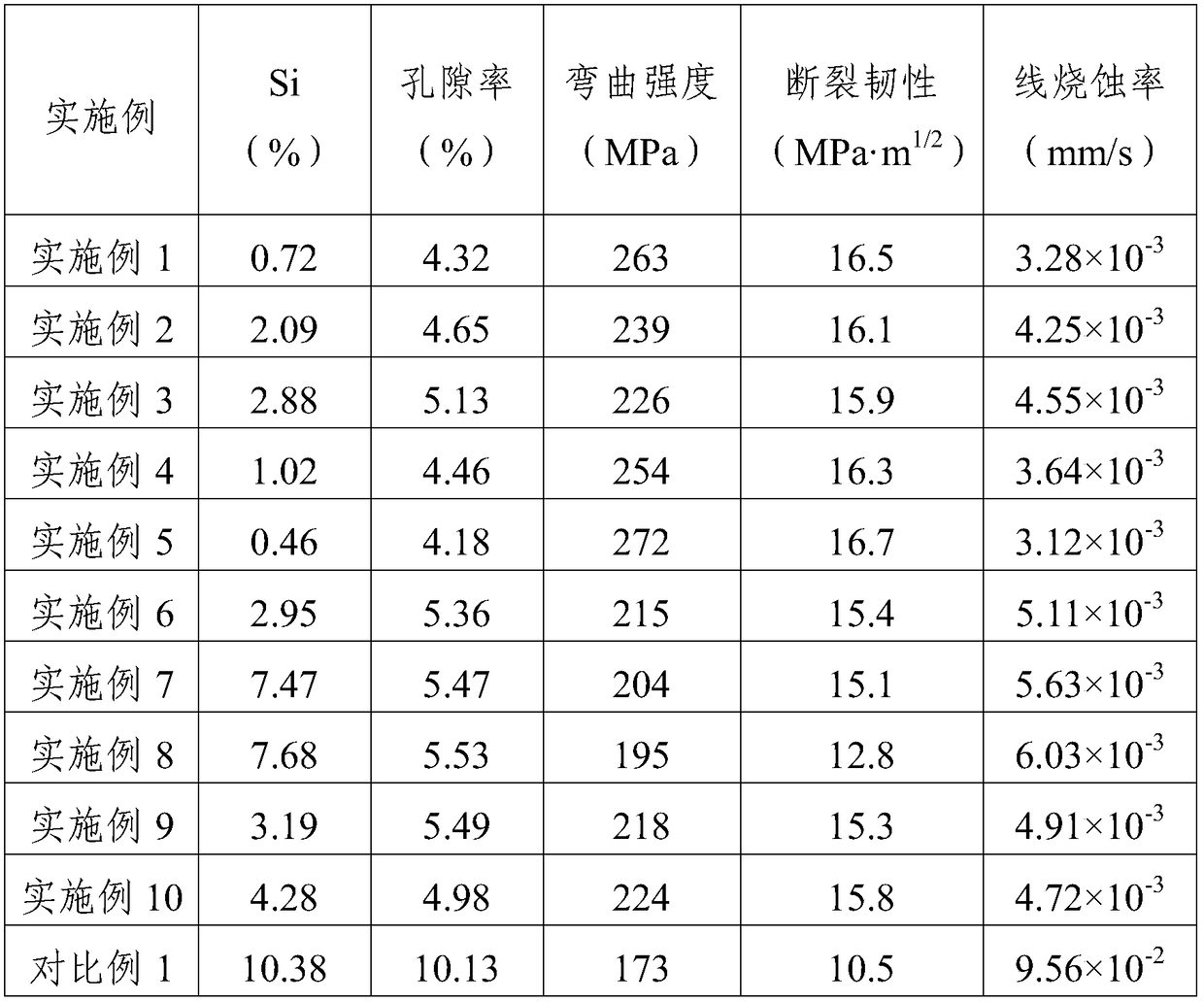

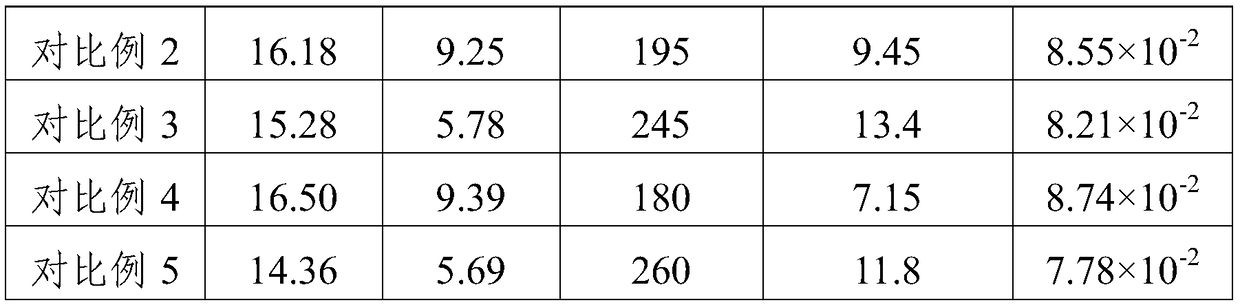

[0074] The performance test and the free content test in different matrix phases of the C / C-SiC composite material prepared in this example were carried out using the same test method as in Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com