Carbon nano tubes (CNTs) and graphene nano flakes (GNFs) synergetic enhanced aluminum-based composite and preparation method

An aluminum-based composite material and nano-carbon material technology, applied in the field of aluminum-based composite materials, can solve problems such as poor graphene binding effect, and achieve the effects of excellent and reliable material performance, fast reaction rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

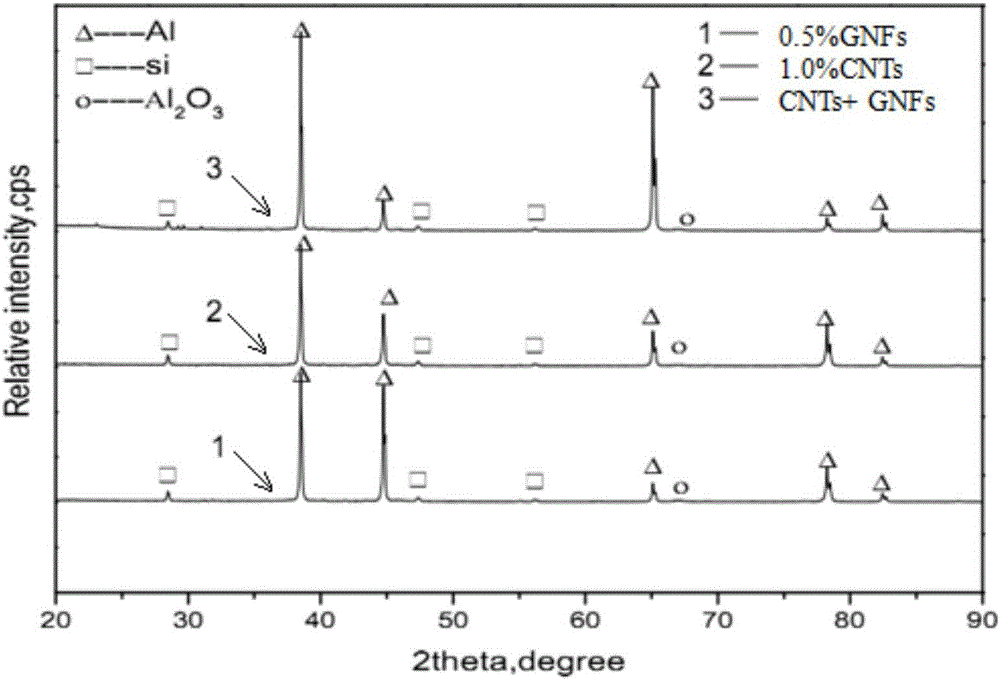

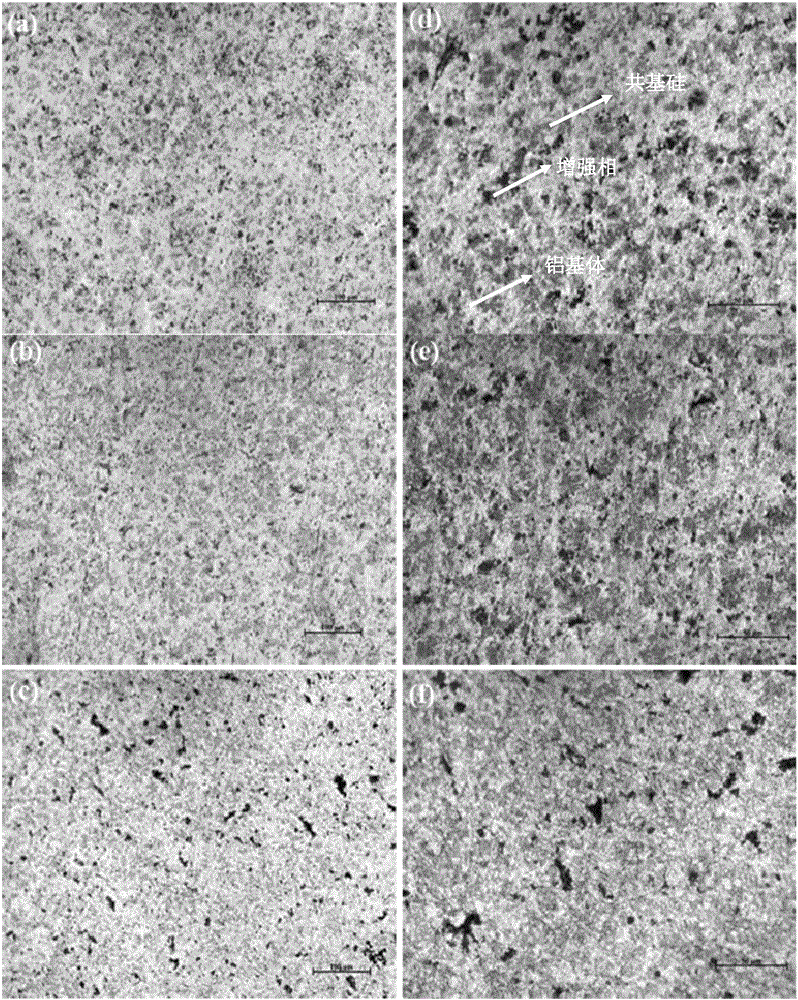

[0088] The test samples in the experiment in this embodiment are aluminum matrix composite materials reinforced by CNTs and GNFs alone and mixed with CNTs and GNFs. It is necessary to determine the content of nano-carbon materials in these three samples in advance. Therefore, we used the method of hot pressing and sintering to prepare aluminum matrix composites with various contents of CNTs, GNFs single reinforcement and CNTs and GNFs mixed reinforcement, tested their hardness, and determined the three composites in the next experiment by comparing the hardness. The content of material nano-carbon material (as shown in Table 1).

[0089] Table 1 Hardness table of composite materials prepared by hot pressing and sintering

[0090]

[0091] It can be drawn from Table 1 that the contents of the corresponding nano-carbon materials with the highest hardness of the three composite materials are 1.0% GNT, 0.5% GNFs, 0.25% GNFs+0.75% CNTs, and the amount of silicon in the aluminum-...

Embodiment 2

[0095] Determine Reagent Concentration

[0096] This experiment is mainly used to prepare surface-modified CNTs and GNFs. If the concentration of the aqueous solution used for surface modification is too high, the modification effect of CNTs and GNFs will be weakened, and the active functional groups grafted to the surface will desorb, and if the concentration of the aqueous solution is too low, the modification effect will not be achieved.

[0097] The modified carbon nanotubes were prepared by successively using gallic acid aqueous solutions with concentrations of 5 μg / ml, 10 μg / ml and 20 μg / ml. Fourier transform infrared spectroscopy was used for characterization and analysis, and CNTs (pure CNTs) without gallic acid aqueous solution were used for comparison. It was found that the peak shape of the Fourier transform infrared spectrum of graphene without gallic acid aqueous solution treatment was wider and the peak was weaker. However, the CNTs treated with gallic acid a...

Embodiment 3

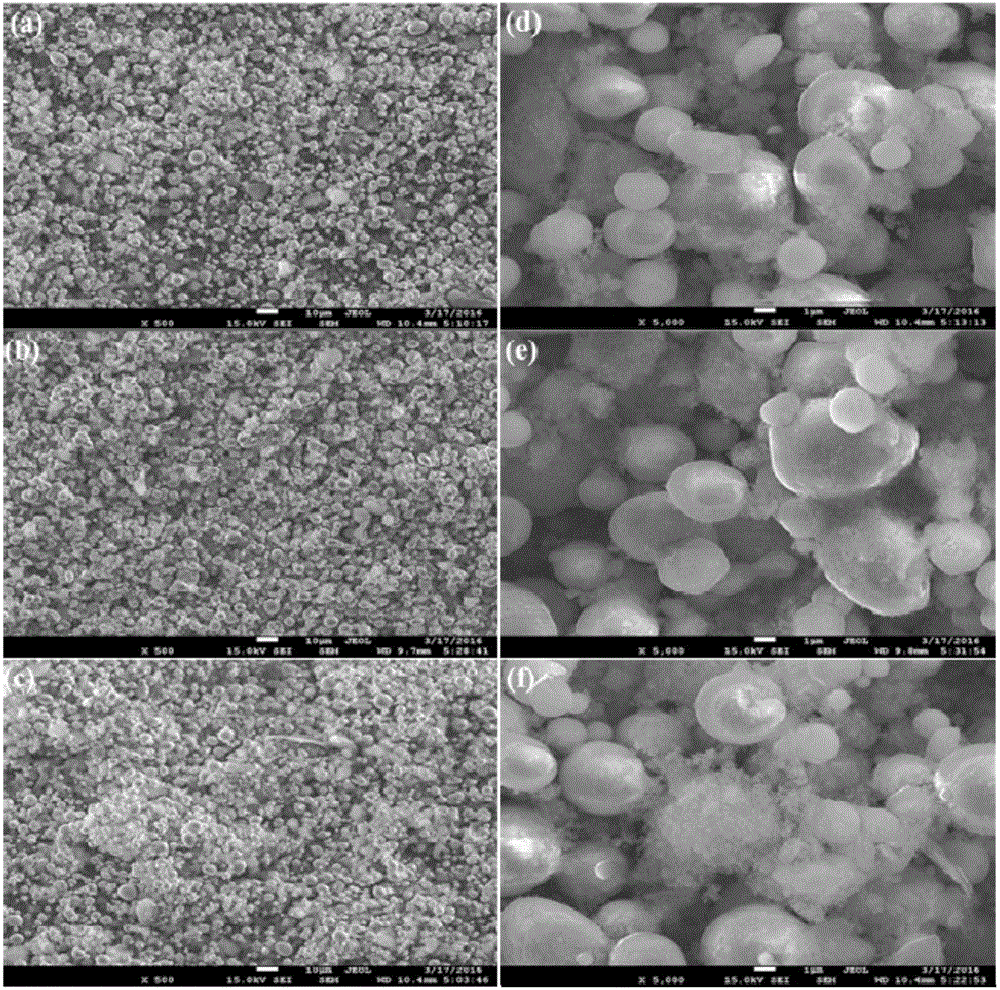

[0105] Preparation of composite powder

[0106] First, number the ball milling tanks with the same type and quantity of agate balls in the three tanks respectively, according to the ingredient data in Table 2, add the corresponding raw materials into each tank in the order of density from small to large, and then add an appropriate amount of agate balls. Butanol is added as a process control agent to prevent powder cold welding and sticking to the wall, and finally the ball mill jar is put into the WL-1 planetary ball mill for ball milling and mixing for 1.5h. By ball milling, the powder can be further refined and uniform and can improve the dispersion of CNTs and GNFs in the matrix.

[0107] After ball milling, pour the mixed powder and agate balls into a metal sieve, place a stainless steel plate directly below the metal sieve to receive the powder, shake the sieve repeatedly with both hands, and finally the composite powder is sieved into the stainless steel plate, and pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com