Large size tubular solid oxide fuel cell and preparation thereof

A solid oxide, fuel cell technology, applied in solid electrolyte fuel cells, fuel cell components, and final product manufacturing, can solve problems such as bending deformation and reduction, and achieve low manufacturing costs, simple processes, and easy to master Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

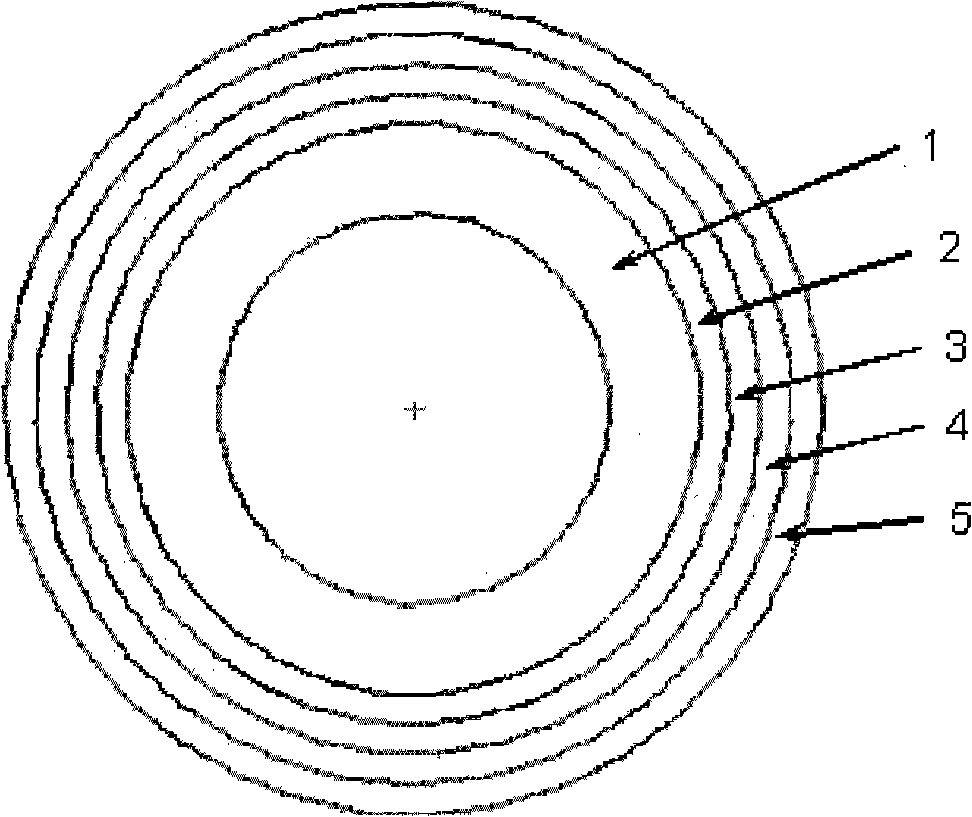

[0037] Example 1 Dip molding NiO-YSZ / SSZ / LSM-SSZ tubular solid oxide fuel cell

[0038] Take by weighing 100g3YSZ (3YSZ, 3mol% Y2O3 doped tetragonal polycrystalline ZrO2), 60g NiO, obtain supporting anode mixed powder; Take by weighing 50gSSZ (10mol% scandium oxide fully stable zirconia) electrolyte powder; Take by weighing 30gLSM20 (20mol% SrO-doped LaMnO3), 10gSSZ (10mol% scandium oxide fully stabilized zirconia) to obtain active cathode mixed powder. Mixed solvents of methyl ethyl ketone and ethanol were added respectively, about 6wt% triethanolamine (TEA) dispersant was added to the supporting anode, and about 2wt% triethanolamine dispersant was added to the electrolyte and active cathode respectively. Mixed by ball milling for 1 hour. Then add about 10wt% dibutyl phthalate and polyvinyl alcohol 200 two plasticizers and about 5wt% polyvinyl butyral binder for the supporting anode, and add about 6wt% ortho Dibutyl phthalate and polyvinyl alcohol 200 two plasticizers and a...

Embodiment 2

[0039] Example 2 Dip NiO-YSZ / NiO-SSZ / SSZ / LSM-SSZ Tubular Solid Oxide Fuel Cell

[0040] On the basis of Example 1, the active anode layer was added, that is, the active anode was impregnated once after the supporting anode was released from the mold, and then the electrolyte was impregnated after drying. The slurry of the active anode is prepared as follows: Weigh 50gSSZ (10% scandium oxide fully stabilized zirconia), and 30gNiO to obtain the active anode mixed powder; add methyl ethyl ketone and ethanol mixed solvent, add about 2wt% triethanolamine dispersant, Ball mill for 1 hour to mix; then add about 8wt% dibutyl phthalate and polyvinyl alcohol 200 plasticizers and about 3wt% polyvinyl butyral binder, and then ball mill for 2 hours to mix; After being sieved through a sieve and vacuum degassed, the active anode slurry is obtained.

Embodiment 3

[0041] Example 3 Dip NiO-YSZ / NiO-SSZ / SSZ / LSM-SSZ / LSM Tubular Solid Oxide Fuel Cell

[0042] On the basis of Example 2, the charging cathode layer was added, that is, the charging cathode was impregnated twice after the active cathode was impregnated, and after drying, the active cathode and the charging cathode were sintered at 1200° C. for 3 hours. The slurry preparation of the electricity collecting cathode is as follows: weigh 50g LSM20 (20mol% SrO-doped LaMnO3) powder; add butanone and ethanol mixed solvent, add about 2wt% triethanolamine dispersant, and ball mill for 1 hour to mix; Then add about 6wt% dibutyl phthalate and two kinds of plasticizers of polyvinyl alcohol 200 and about 3wt% polyvinyl butyral binder, and ball mill for 2 hours to mix; After vacuum degassing treatment, the cathode slurry for collecting electricity is obtained.

[0043] Battery Power Generation Experiment

[0044] The cathode side of the tubular SOFC uses a platinum grid for electricity collec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com