Positive electrode material for ultrahigh-power-density lithium carbon fluoride battery and preparation method and application of positive electrode material

A positive electrode material and power density technology, applied in the battery field, can solve problems affecting battery capacity performance and application limitations, and achieve the effects of reducing battery resistance, reducing ion transmission resistance, and reducing reaction polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

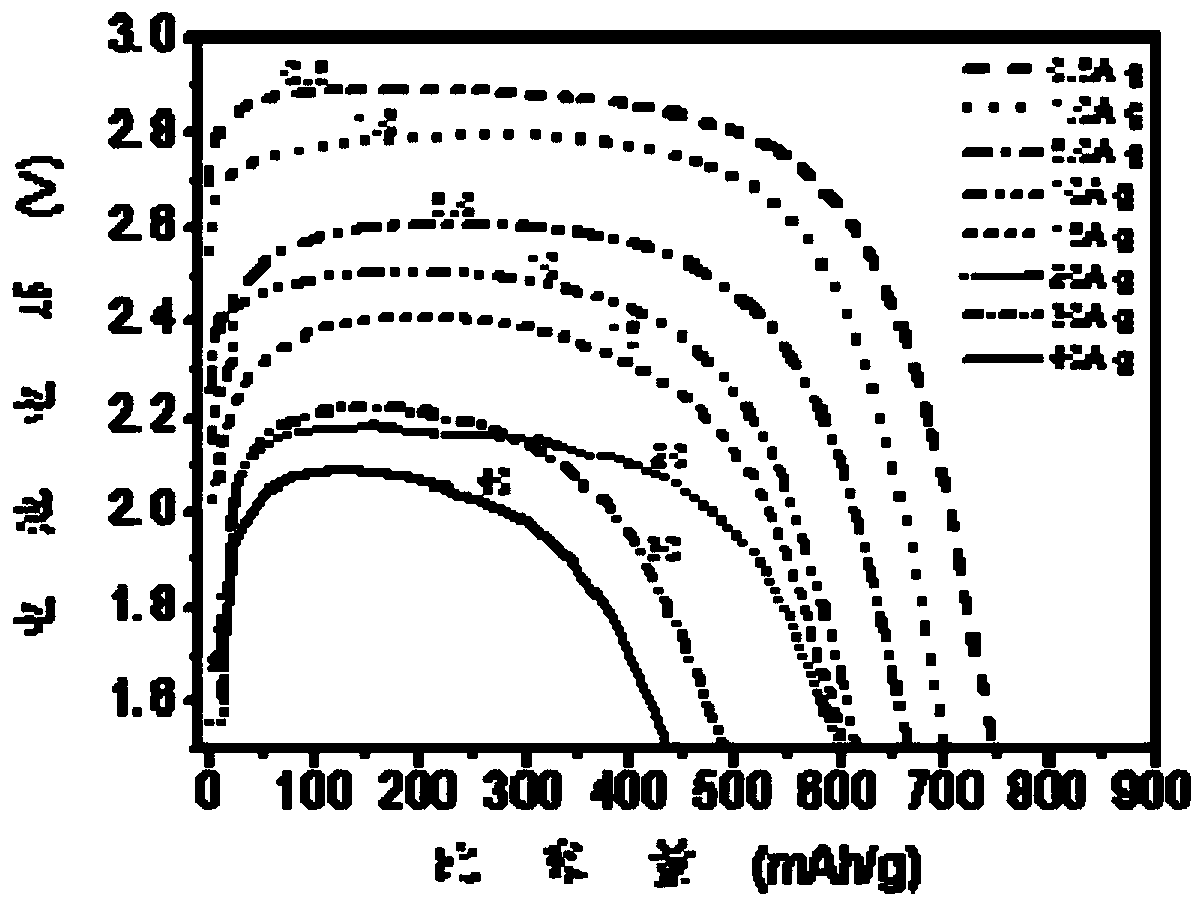

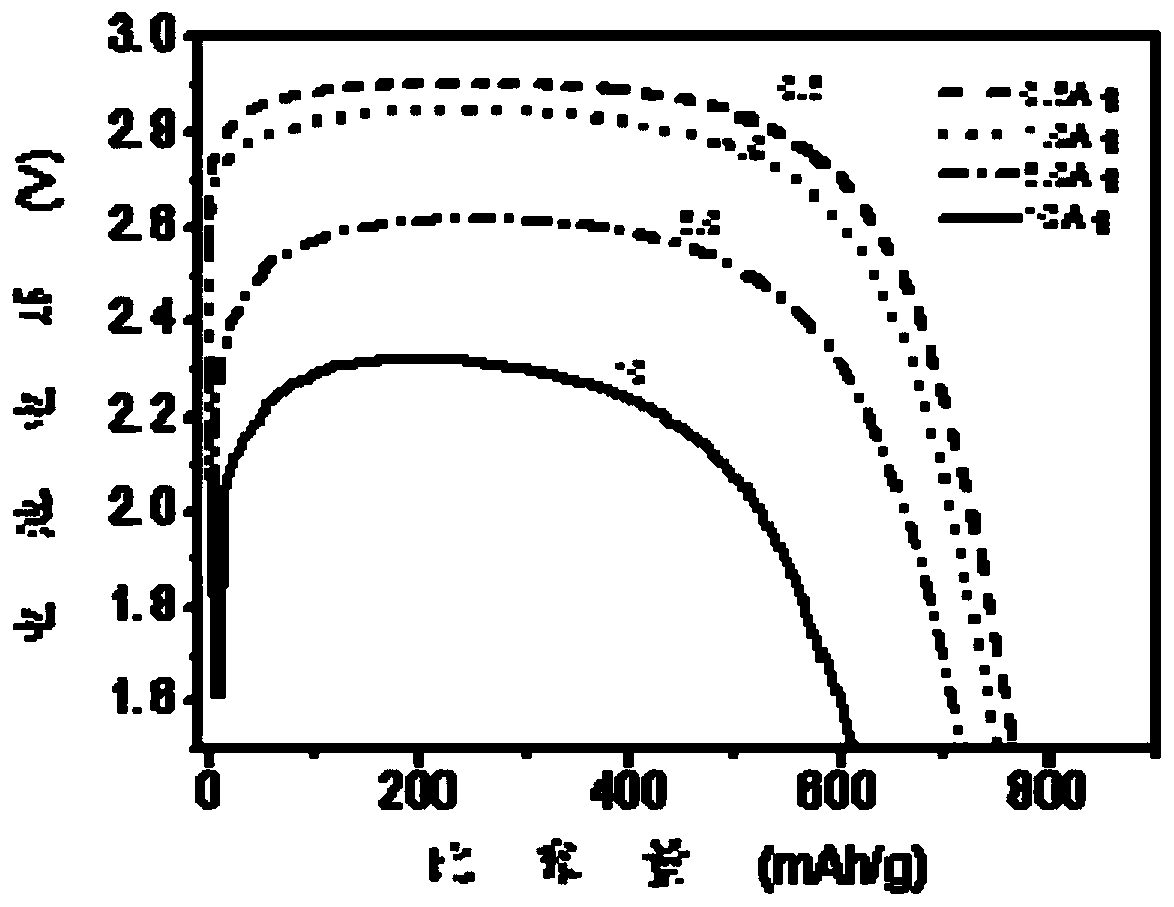

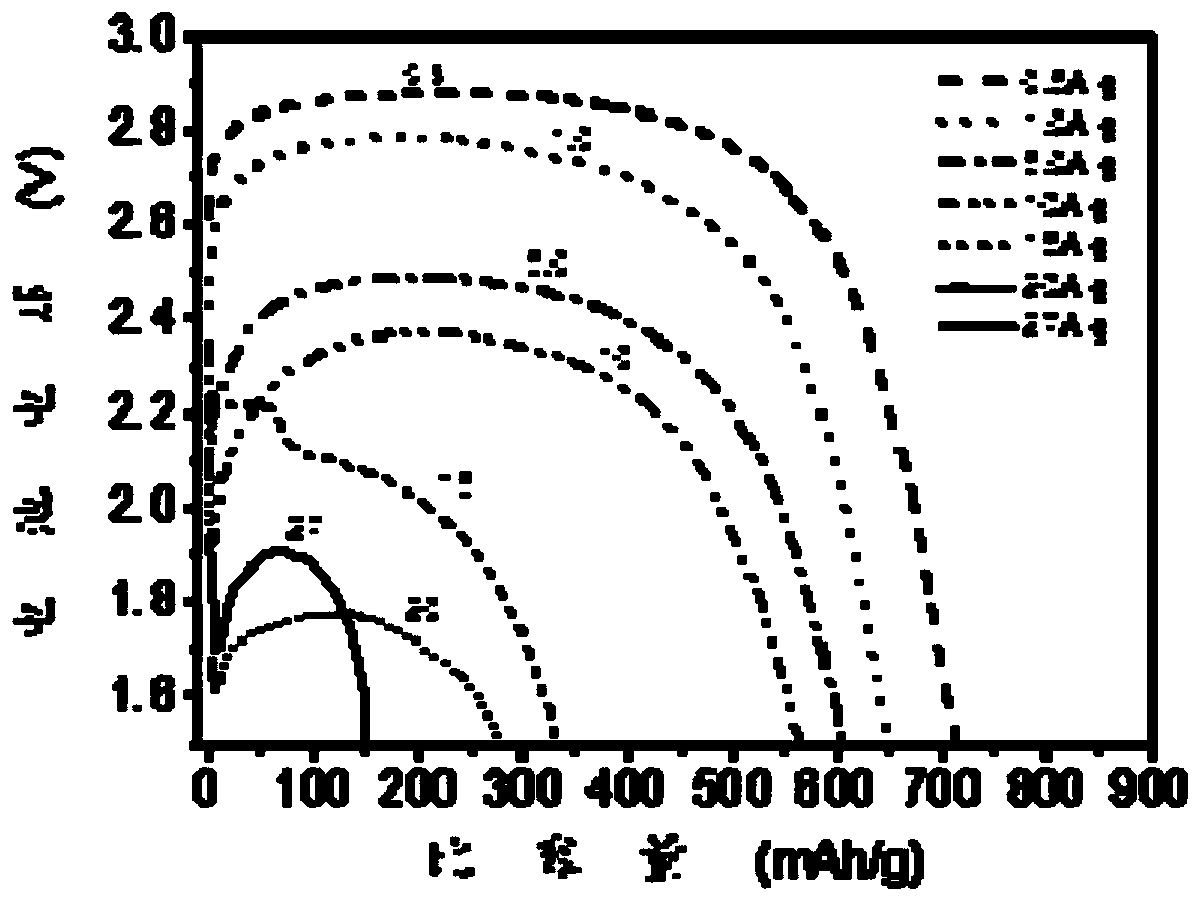

Image

Examples

preparation example Construction

[0028] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0029] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0031] The steps for preparing the ultra-high power density lithium carbon fluoride battery described in the present invention are as follows:

[0032] Step 1: Add 0.8g of super conductive carbon black and 20g of polyvinylidene fluoride solution with a mass fraction of 5% into a mixer and mix for 30 minutes. The solvent in the polyvinylidene fluoride solution is nitrogen methylpyrrolidone;

[0033] Step 2: Add 8g fluorinated graphene and 70g nitrogen methyl pyrrolidone, stir and mix for 1h, then add 0.2g nano-carbon fiber and mix for 6h to make a uniform positive electrode slurry, wherein the fluorine content of fluorinated graphene is 52% by mass , the specific surface area is 260m 2 / g;

[0034] Step 3: Apply the obtained positive electrode slurry evenly on the carbon-coated aluminum foil by doctor blade coating, with a coating thickness of 150 μm;

[0035] Step 4: Dry at 110°C under normal pressure for 1 hour, then vacuum-dry at 110°C for 8 hours to make a positive electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com