Charged nozzle, pre-charging device comprising same and method for charging dust-containing flue gas by using pre-charging device

A pre-charging, nozzle technology, applied in cleaning methods and utensils, chemical instruments and methods, particle charging/ionizing places, etc., can solve the problems of bursting of insulating parts, uneconomical, high-voltage electrical creepage breakdown, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] This embodiment provides a Figure 11 to Figure 14 As shown in the pre-charging device, the pre-charging device includes a flue gas circulation pipe 11 with a diameter of 20 cm and a circular cross-section. Along the flue gas flow direction, four groups of charged nozzle assemblies are equidistantly arranged on the pipe wall of the flue gas circulation duct 11 (in order to ensure that the lines of the picture are clear and simplify the drawing steps, only three groups of charged nozzle assemblies are shown in the figure, but Only one group of charging nozzle components is simplified, and the installation position of the charging nozzle 13 still adopts Figure 11 to Figure 14 installation method), each group of charging nozzle assemblies includes two charging nozzles 13 arranged along the circumference of the flue gas circulation pipe 11 .

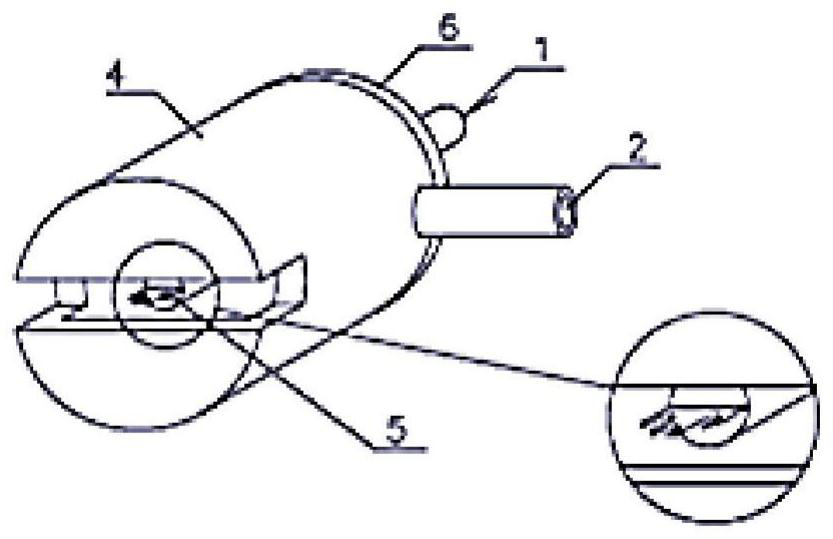

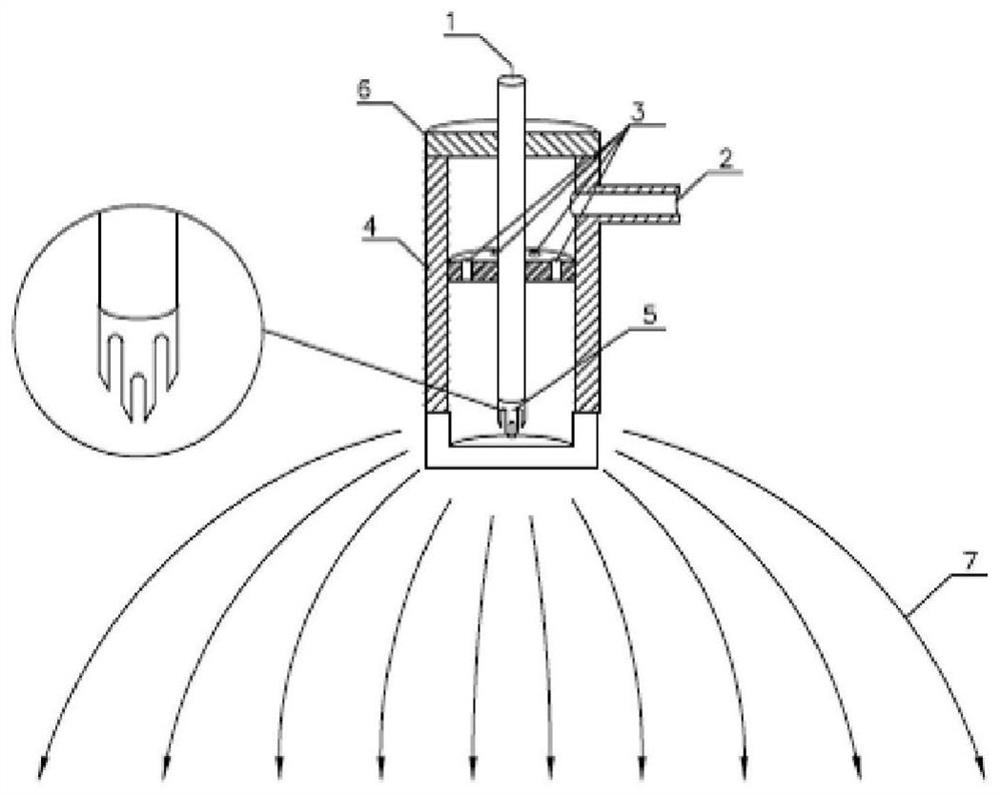

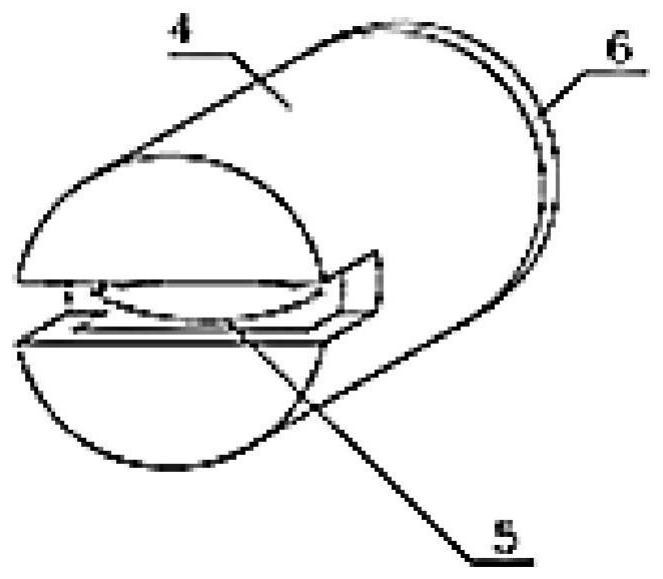

[0108] The charged nozzle 13 adopts such as image 3 and Figure 4As shown in the fan-shaped discharge electrode 5, the length o...

Embodiment 2

[0115] This embodiment provides a Figure 15 and Figure 16 The pre-charging device shown, the pre-charging device includes a flue gas circulation pipe 11 with a diameter of 40 cm and a circular cross-section. Along the flue gas flow direction, three groups of charged nozzle assemblies are equidistantly arranged on the pipe wall of the flue gas circulation pipe 11, and each group of charged nozzle assemblies includes four charged nozzles 13 arranged upward along the circumference of the flue gas circulation pipe 11, The charged nozzle 13 adopts such as image 3 and Figure 4 As shown in the fan-shaped discharge electrode 5, the length of the discharge port at the end of the charging nozzle 13 extending into the flue gas circulation duct 11 is 5 cm, and two metal partitions 12 are vertically arranged inside the flue gas circulation duct 11 along the direction of the flue gas flow. , the flue gas circulation duct 11 is divided into four independent flue gas circulation sub-pi...

Embodiment 3

[0122] This embodiment provides a Figure 17 and Figure 18 The pre-charging device shown, the pre-charging device includes a square flue gas circulation pipe 11 with a cross-section of 70×70cm, and five pipes are equidistantly arranged on the pipe wall of the flue gas circulation pipe 11 along the flue gas flow direction. Groups of charging nozzle assemblies (in order to ensure that the lines of the picture are clear and simplify the drawing steps, only three groups of charging nozzle assemblies are shown in the figure, but only two groups of charging nozzle assemblies are omitted in number, the installation position of charging nozzle 13 still use Figure 17 and Figure 18 installation method). Each group of charged nozzle assemblies includes four charged nozzles 13 disposed along the circumference of the flue gas flow duct 11 , and the four charged nozzles 13 are evenly arranged on four sides of the flue gas flow duct 11 . The charged nozzle 13 adopts such as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com