High-specific-capacity and high-power alkaline aluminum-air battery electrolyte and preparation method thereof

An aluminum-air battery and electrolyte technology, which is applied in the field of electrochemistry, can solve the problems of reduced anode utilization, severe hydrogen evolution corrosion, and insufficient capacity density, and achieve the goal of increasing discharge current density, improving anode utilization, and increasing solution conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

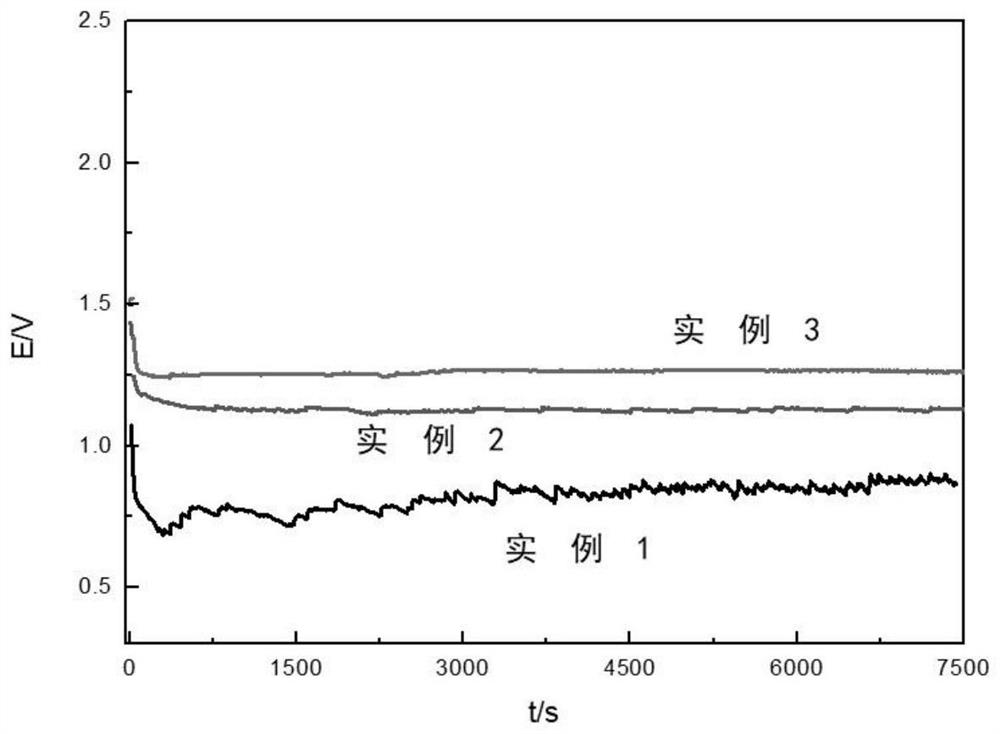

Embodiment 1

[0016] Configure potassium hydroxide aqueous solution, add zinc oxide, stir and dissolve, then add potassium fluoride, potassium citrate and potassium permanganate in sequence, and add polyethylene glycol after the solution is cooled, so that the composition of each substance in the prepared electrolyte Divided into:

[0017] Potassium hydroxide 37wt%, potassium fluoride 2.3wt%, potassium citrate 6wt%, zinc oxide 0.2wt%, polyethylene glycol 6mmol / L, potassium permanganate 0.2g / L, and the balance is water.

[0018] The prepared electrolyte is added to the aluminum-air battery, the negative pole is a 3N9 pure aluminum plate, the positive pole is a commercial air electrode, and the main components are manganese dioxide, acetylene black, and nickel mesh. Connect the positive and negative electrodes of the battery to the electrochemical workstation for data collection, and calculate the mass loss of the aluminum sheet before and after discharge. The test results are as follows:

...

Embodiment 2

[0021] Configure potassium hydroxide aqueous solution, add zinc oxide, stir and dissolve, then add potassium fluoride, potassium citrate and potassium permanganate in sequence, and add polyethylene glycol after the solution is cooled, so that the composition of each substance in the prepared electrolyte Divided into:

[0022] Potassium hydroxide 37wt%, potassium fluoride 2.3wt%, potassium citrate 6wt%, zinc oxide 0.2wt%, polyethylene glycol 4mmol / L, potassium permanganate 0.2g / L, and the balance is water.

[0023] The prepared electrolyte is added to the aluminum-air battery, the negative pole is a 3N9 pure aluminum plate, the positive pole is a commercial air electrode, and the main components are manganese dioxide, acetylene black, and nickel mesh. Connect the positive and negative electrodes of the battery to the electrochemical workstation for data collection, and calculate the mass loss of the aluminum sheet before and after discharge. The test results are as follows:

...

Embodiment 3

[0026] Configure potassium hydroxide aqueous solution, add zinc oxide, stir and dissolve, then add potassium fluoride, potassium citrate and potassium permanganate in sequence, and add polyethylene glycol after the solution is cooled, so that the composition of each substance in the prepared electrolyte Divided into:

[0027] Potassium hydroxide 37wt%, potassium fluoride 2.3wt%, potassium citrate 6wt%, zinc oxide 0.3wt%, polyethylene glycol 6mmol / L, potassium permanganate 0.2g / L, and the balance is water.

[0028] The prepared electrolyte is added to the aluminum-air battery, the negative pole is a 3N9 pure aluminum plate, the positive pole is a commercial air electrode, and the main components are manganese dioxide, acetylene black, and nickel mesh. Connect the positive and negative electrodes of the battery to the electrochemical workstation for data collection, and calculate the mass loss of the aluminum sheet before and after discharge. The test results are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com