Sea cell Mg-Li-Zn alloy electrode modified by yttrium-rich mischmetal element and preparing method

An alloy electrode, mixed rare earth technology, applied in battery electrodes, electrodes of primary batteries, immersed batteries, etc., can solve the problems of short service life and low discharge current density, reduce production costs, improve corrosion resistance and use. life, the effect of increasing the discharge current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

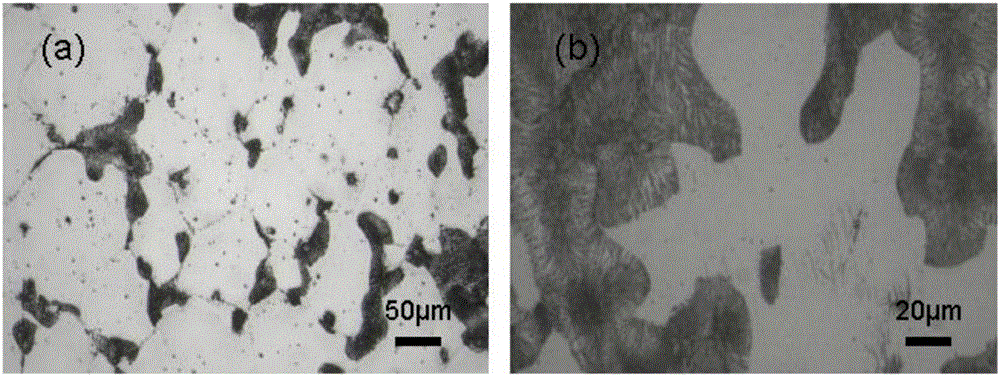

Image

Examples

Embodiment 1

[0026] Example 1 Multi-element Mg-15Li-2.5Zn-2.5RE alloy electrode

[0027] The composition (mass fraction) of the alloy is: Mg: 80%, Li: 15%, Zn: 2.5%, RE: 2.5%.

[0028] The preparation steps of the alloy electrode: In the vacuum melting furnace, first preheat the crucible to dark red, add the dried pure magnesium ingot, and start to feed SF 6 +Ar mixed gas; in SF 6 Under the protection of +Ar gas, continue to heat up to 700°C, and add pure zinc ingots; when the temperature rises to 780°C, add magnesium-yttrium-rich mixed rare earth (Mg-RE) master alloy, and stir evenly after all the raw materials are melted; after the alloy is smelted , remove the powdered magnesium oxide and covering agent mixture on the surface, let it stand at 780°C for more than 30min, and then pour; after pouring, the obtained alloy sample is kept at 300°C for 10h in a vacuum heat treatment furnace; the multi-component Mg-15Li- 2.5Zn-2.5RE alloy electrodes.

[0029] The discharge performance of the ...

Embodiment 2

[0030] Example 2 Multi-element Mg-11.9Li-1.5Zn-1.6RE alloy electrode

[0031] The composition (mass fraction) of the alloy is: Mg: 85%, Li: 11.9%, Zn: 1.5%, RE: 1.6%.

[0032] The preparation steps of the alloy electrode: In the vacuum melting furnace, first preheat the crucible to dark red, add the dried pure magnesium ingot, and start to feed SF 6 +Ar mixed gas; in SF 6 Under the protection of +Ar gas, continue to heat up to 710°C, and add pure zinc ingots; when the temperature rises to 790°C, add magnesium-yttrium-rich mixed rare earth (Mg-RE) master alloy, and stir evenly after all the raw materials are melted; after the alloy is smelted , remove the powdered magnesium oxide and covering agent mixture on the surface, let it stand at 790°C for more than 30min, and then pour; after pouring, the obtained alloy sample is kept at 300°C for 10h in a vacuum heat treatment furnace; the multivariate 80Mg-15Li- 2.5Zn-2.5RE alloy electrode.

[0033] The electrochemical performance...

Embodiment 3

[0034] Example 3 Multivariate 90Mg-5Li-0.2Zn-3RE Alloy Electrode

[0035] The composition (mass fraction) of the alloy is: Mg: 90%, Li: 9.3%, Zn: 0.5%, RE: 0.2%.

[0036] The preparation steps of the alloy electrode: In the vacuum melting furnace, first preheat the crucible to dark red, add the dried pure magnesium ingot, and start to feed SF 6 +Ar mixed gas; in SF 6 Under the protection of +Ar gas, continue to heat up to 715°C, and add pure zinc ingots; when the temperature rises to 800°C, add magnesium-yttrium-rich mixed rare earth (Mg-RE) master alloy, and stir evenly after all the raw materials are melted; after the alloy is smelted , remove the powdered magnesium oxide and covering agent mixture on the surface, let it stand at 800°C for more than 30min, and then pour; after pouring, the obtained alloy sample is kept at 300°C for 10h in a vacuum heat treatment furnace; the multi-component 90Mg-9.3Li -0.5Zn-0.2RE alloy electrode.

[0037] The electrochemical performance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com