Method for preparing cathode material for high capacity lithium ion battery

A technology of lithium-ion batteries and negative electrode materials, which is applied in the direction of electrode manufacturing, etc., can solve the problems of powdering and deactivation of electrode materials, and achieve the effect of increased surface roughness and firm and tight interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

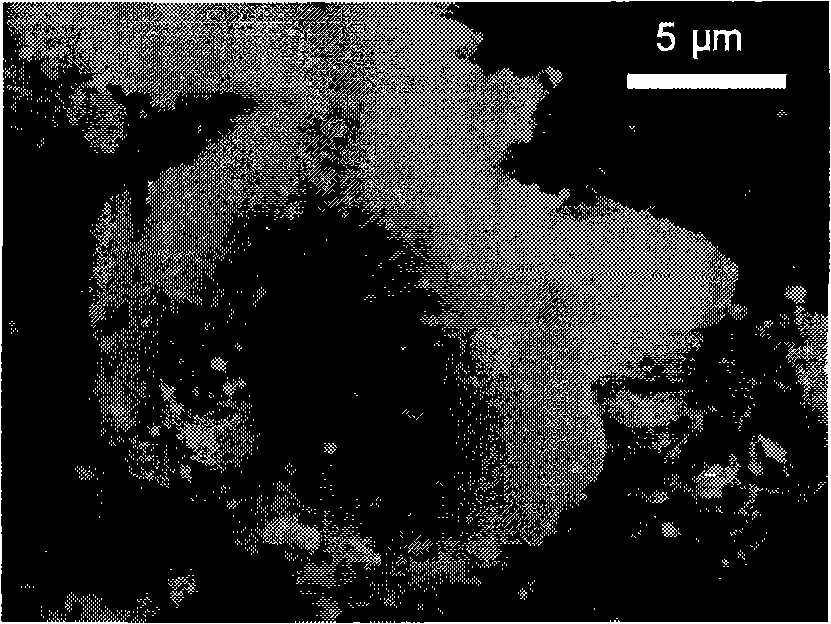

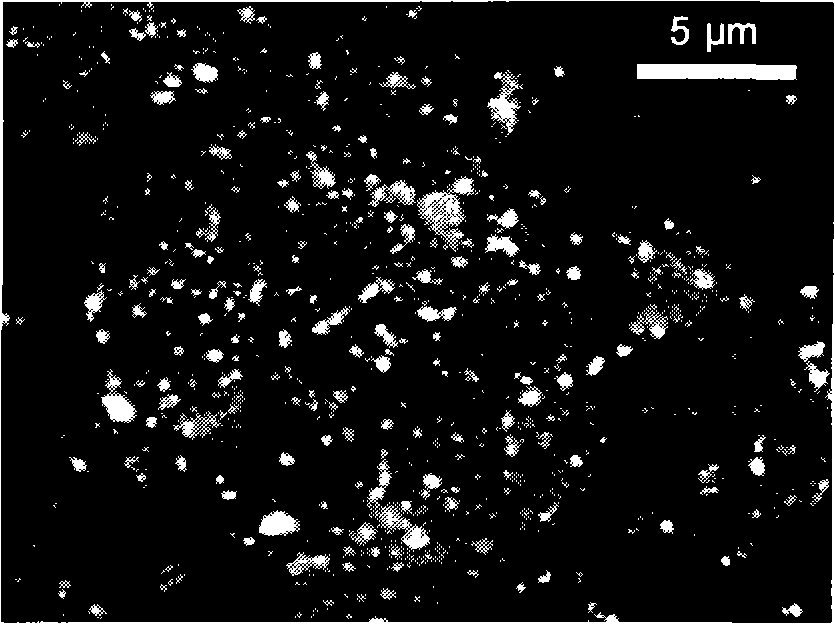

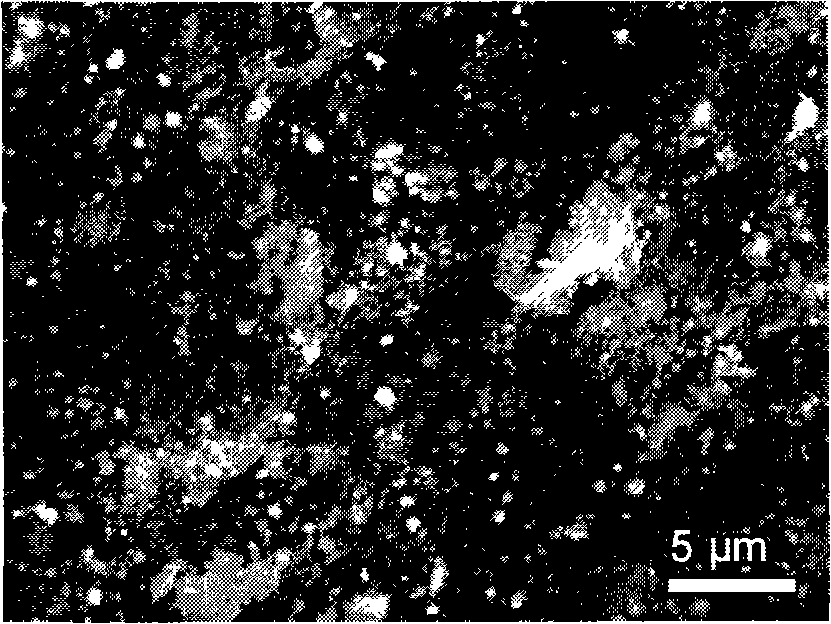

[0028] Weigh mesocarbon microspheres (76wt.%) and SnO 2 (24wt.%) of the mixture was 0.5 g in total, and after mechanical ball milling for 50 minutes, it was placed in a heating furnace and reacted at 800° C. for 40 minutes. The amount of oxygen introduced during the reaction is the starting SnO 2 3 times the oxygen content, the inert gas is N 2 , The amount of inert gas added is 5 times that of oxygen. The scanning electron micrographs of the samples after the reaction are shown (Figure 1(a)-(b)), and the SnO 2 Small particles are uniformly dispersed on the surface of carbon microspheres. The test results of the conventional lithium-ion battery negative electrode evaluation method show that the sample has a high specific capacity (>500mAh / g) and excellent cycle performance. For detailed data comparison, see ( image 3 ).

Embodiment 2

[0032] Weigh mesocarbon microspheres (56wt.%) and SnO 2 (44wt.%) of the mixture was 0.5 g in total, and after mechanical ball milling for 90 minutes, it was placed in a heating furnace and reacted at 950° C. for 40 minutes. The amount of oxygen introduced during the reaction is the starting SnO 2 3 times the oxygen content, the inert gas is N 2 , The amount of inert gas added is 7 times that of oxygen. After the reaction, the sample was tested by the conventional lithium-ion battery negative electrode evaluation method, and the results showed that the capacity was still above 450mAh / g after 30 cycles.

Embodiment 3

[0036] Weigh natural graphite balls (75wt.%) and Fe 2 o 3 (25wt.%) of the mixture was 0.5 g in total, and after mechanical ball milling for 90 minutes, it was placed in a heating furnace and reacted at 1500° C. for 20 minutes. The amount of oxygen introduced during the reaction is the starting Fe 2 o 3 The oxygen content is 2 times, the inert gas is Ar, and the addition amount of the inert gas is 15 times of oxygen. After the reaction, the sample was tested by the conventional lithium-ion battery negative electrode evaluation method, and the results showed that the capacity was still above 500mAh / g after 30 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com