High temperature brazing process of super nickel laminated material and Cr18-Ni8 stainless steel

A technology of cr18-ni8 and laminated materials, which is applied in the field of material welding, can solve problems such as welding difficulties, over-burning of super nickel clad layers, welding deformation, etc., and achieve good fluidity and seam filling ability, beautiful brazing seam shape, high temperature The effect of small intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

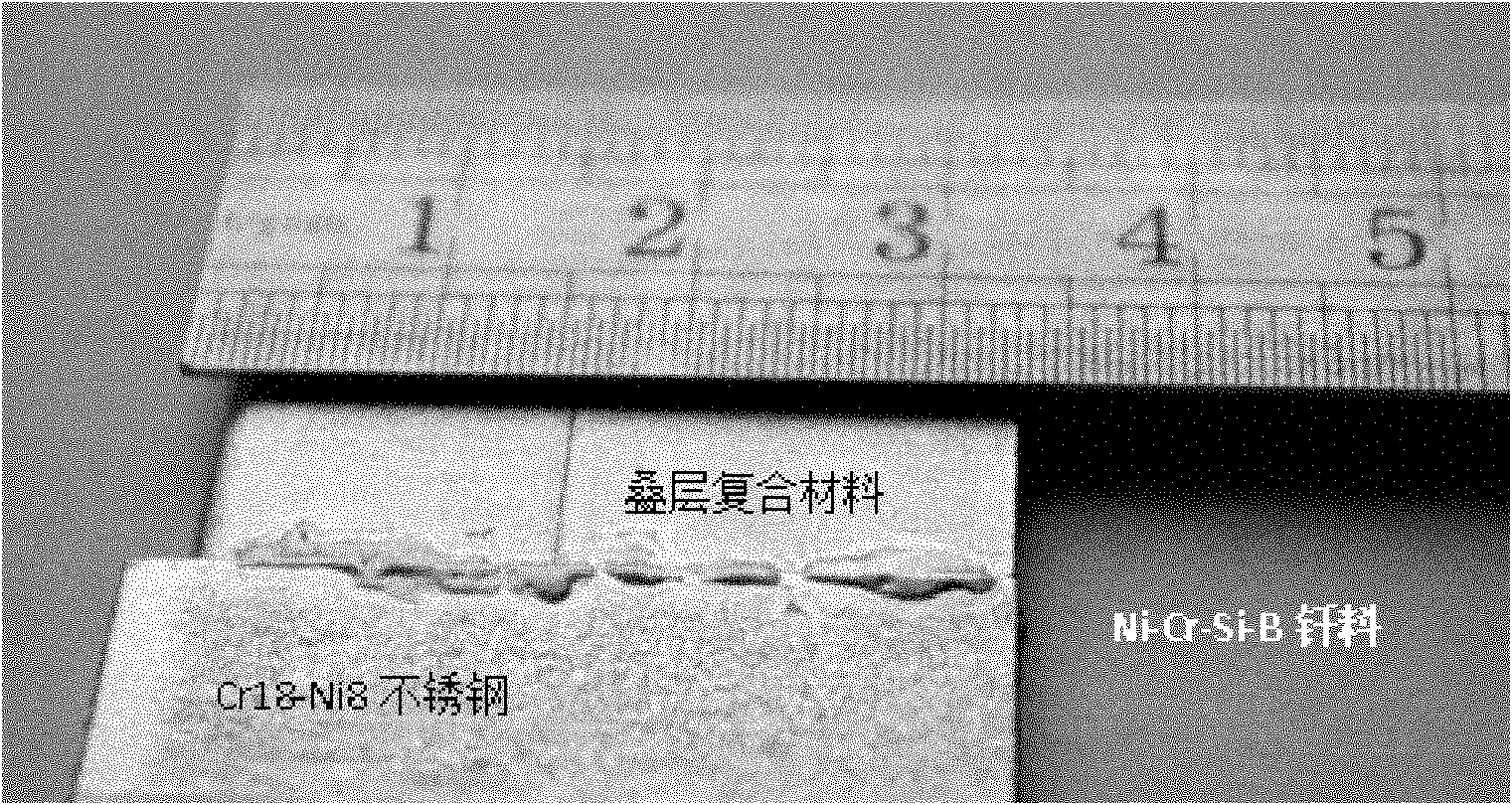

[0027] The super nickel laminated material with a thickness of 2.6mm is butt-brazed with a Cr18-Ni8 stainless steel plate with a thickness of 2.6mm. The length of the connected piece is 30mm and the width is 10mm. The thickness of the cladding layer of the super nickel laminate material is 0.3 mm, and the thickness of the Ni-Cr base layer is 2.0 mm.

[0028] The specific high temperature vacuum brazing process steps are as follows:

[0029] (1) Before welding, place the connected parts in carbon tetrachloride solution for ultrasonic cleaning for 3 minutes, take them out, rinse them with cold water and dry them. Use No. 600 sandpaper to remove the oxide film on the surface of the super nickel laminate material and the stainless steel parts to be connected, rinse with alcohol and blow dry.

[0030] (2) Place the connected parts on the graphite plate of the vacuum chamber covered with mica foil. The function of the mica foil is to prevent the solder and the graphite plate from ...

Embodiment 2

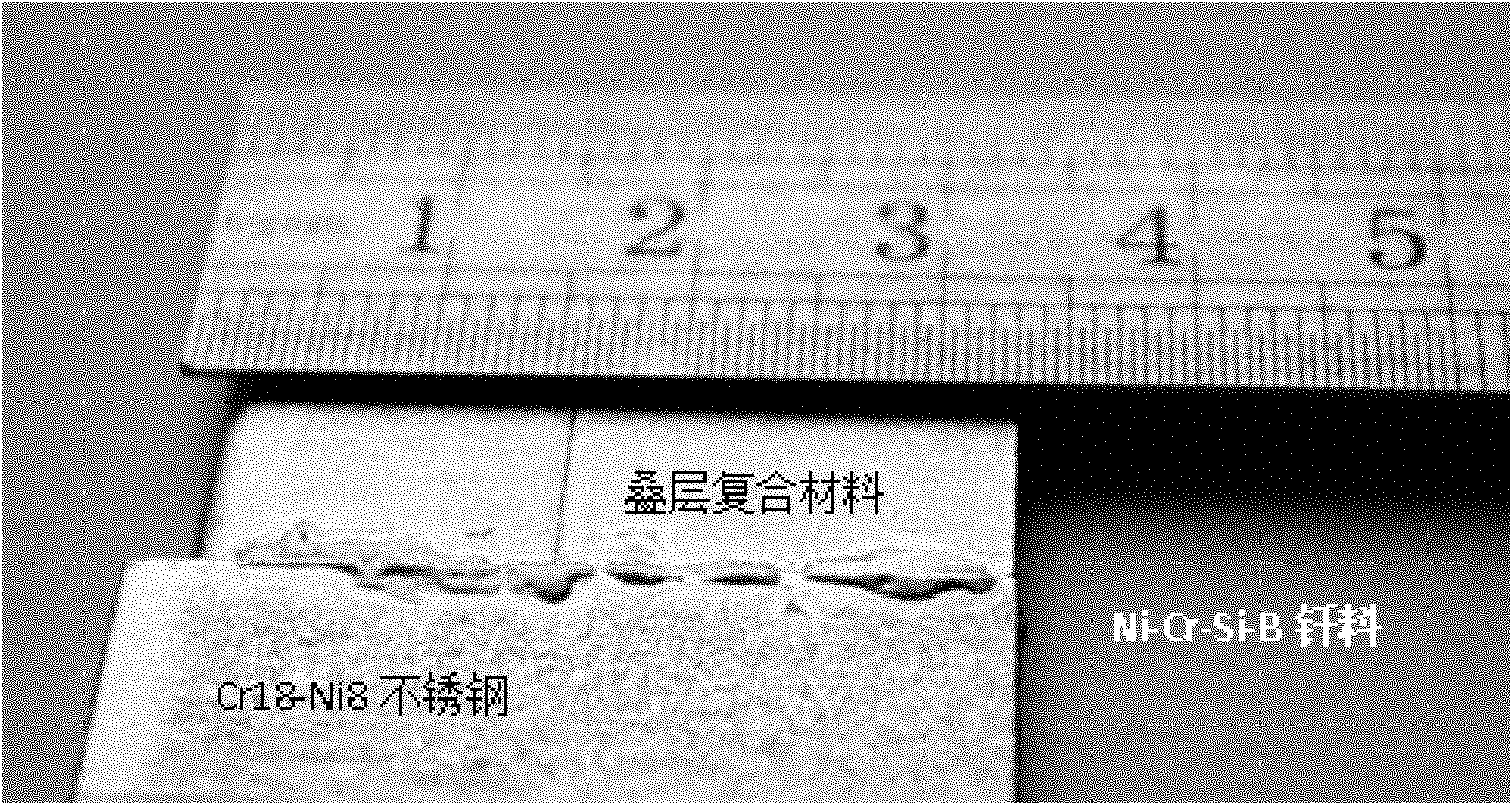

[0035] The super nickel laminate material with a thickness of 3mm is connected at right angles to the Cr18-Ni8 stainless steel with a thickness of 3mm. The length of the connected part is 30mm, the width is 20mm, and the super nickel laminate material is the same size as Cr18-Ni8 stainless steel. The thickness of the cladding layer of the super nickel laminated material is 0.3m, and the thickness of the Ni-Cr alloy base layer is 2.4mm.

[0036] The specific vacuum high temperature brazing process steps are as follows:

[0037] (1) Now grind the laminated composite material and the stainless steel joint to a 45° bevel; place the connected parts in a carbon tetrachloride solution for ultrasonic cleaning for 5 minutes, take them out, rinse them with cold water, and dry them. Use No. 600 sandpaper to remove the super nickel laminate material and the oxide film on the surface of the stainless steel to be brazed, rinse with alcohol and blow dry.

[0038](2) Place the connected par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com