Method for improving mechanical property of silicon-containing arylacetylene resin based composite material

A technology of composite materials and silicon aryne, which is applied in the field of composite materials, can solve the problems of poor mechanical strength, poor processing technology, high curing temperature, etc., and achieve the improvement of flexural modulus, mechanical properties and interlaminar shear strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

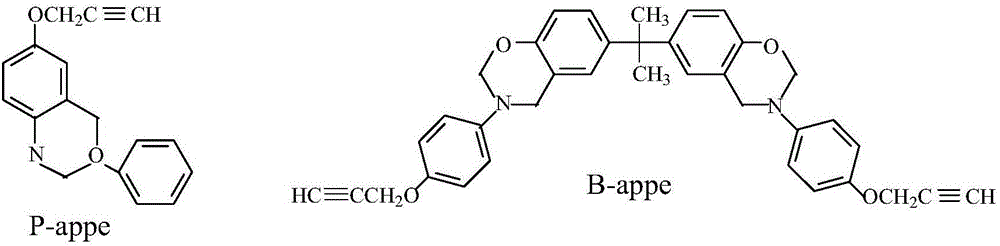

[0046] Phenol (0.2mol), paraformaldehyde 12g (0.4mol) and p-aminophenyl propargyl ether 29.4g (0.2mol) were added stoichiometrically into a 250mL three-necked round-bottom flask equipped with a mechanical stirring device, a thermometer and a condenser. ). Heat to 90°C-110°C under stirring, and react for 30 minutes. After the reaction, the product was dissolved in toluene, ethyl acetate or diethyl ether, washed three times with 1mol / L sodium hydroxide solution, then washed with deionized water until neutral, the organic layer was separated, dried by adding anhydrous sodium sulfate, The solvent was removed by rotary evaporation to obtain the monopropargyl ether type benzoxazine P-appe, which was a yellow-brown viscous liquid with a yield of 83%.

Embodiment 2

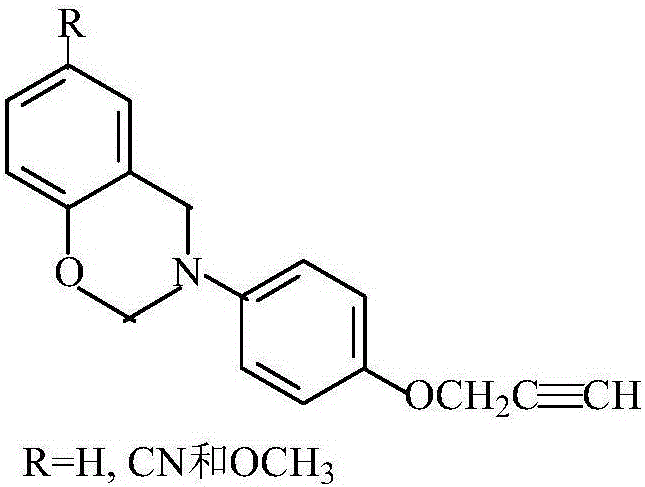

[0048] With reference to the process for preparing P-appe in Example 1, p-cyanophenol replaced phenol as a monohydric phenolic compound and reacted with formaldehyde and p-aminophenyl propargyl ether to prepare monopropargyl ether type benzoxazine CP -appe is a yellow-brown viscous liquid with a yield of 81%.

Embodiment 3

[0050] With reference to the process for preparing P-appe in Example 1, p-methoxyphenol replaced phenol as a monohydric phenolic compound and reacted with formaldehyde and p-aminophenyl propargyl ether to prepare monopropargyl ether type benzoxazine MP-appe is yellow-brown viscous liquid with a yield of 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com