Continuous filament prepreg 3D printing spray head and 3D printer and printing method thereof

A continuous fiber, 3D printing technology, used in 3D object support structures, additive manufacturing, coating devices, etc., can solve the problems of low strength and insignificant increase in strength, and achieve the effect of improving strength and solving little increase in strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention, not to limit the protection scope of the present invention. Improvements and adjustments made by those skilled in the art according to the present invention in practical applications still belong to the protection scope of the present invention.

[0031] In order to better illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

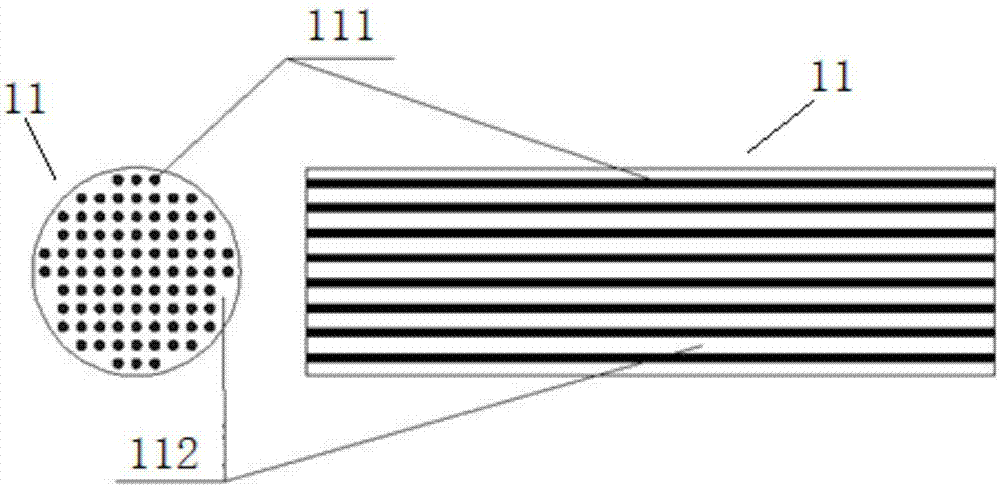

[0032] Such as figure 1 As mentioned above, the continuous fiber prepreg 11 used in the present invention is a continuous fiber reinforced thermoplastic resin-based composite material, and its cross-sectional shape is circular, including continuous fiber 111 and thermoplastic resin 112, wherein the continuous fiber 111 is carbon fiber, glass One of fiber or Kevlar fibers, or a fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com