Clamp improving bending and interlaminar shearing test efficiency of composite material

A technology of interlayer shear and test efficiency, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of time-consuming span, misalignment of the centerline of the indenter of the test fixture and the centerline of the support, and affecting the test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

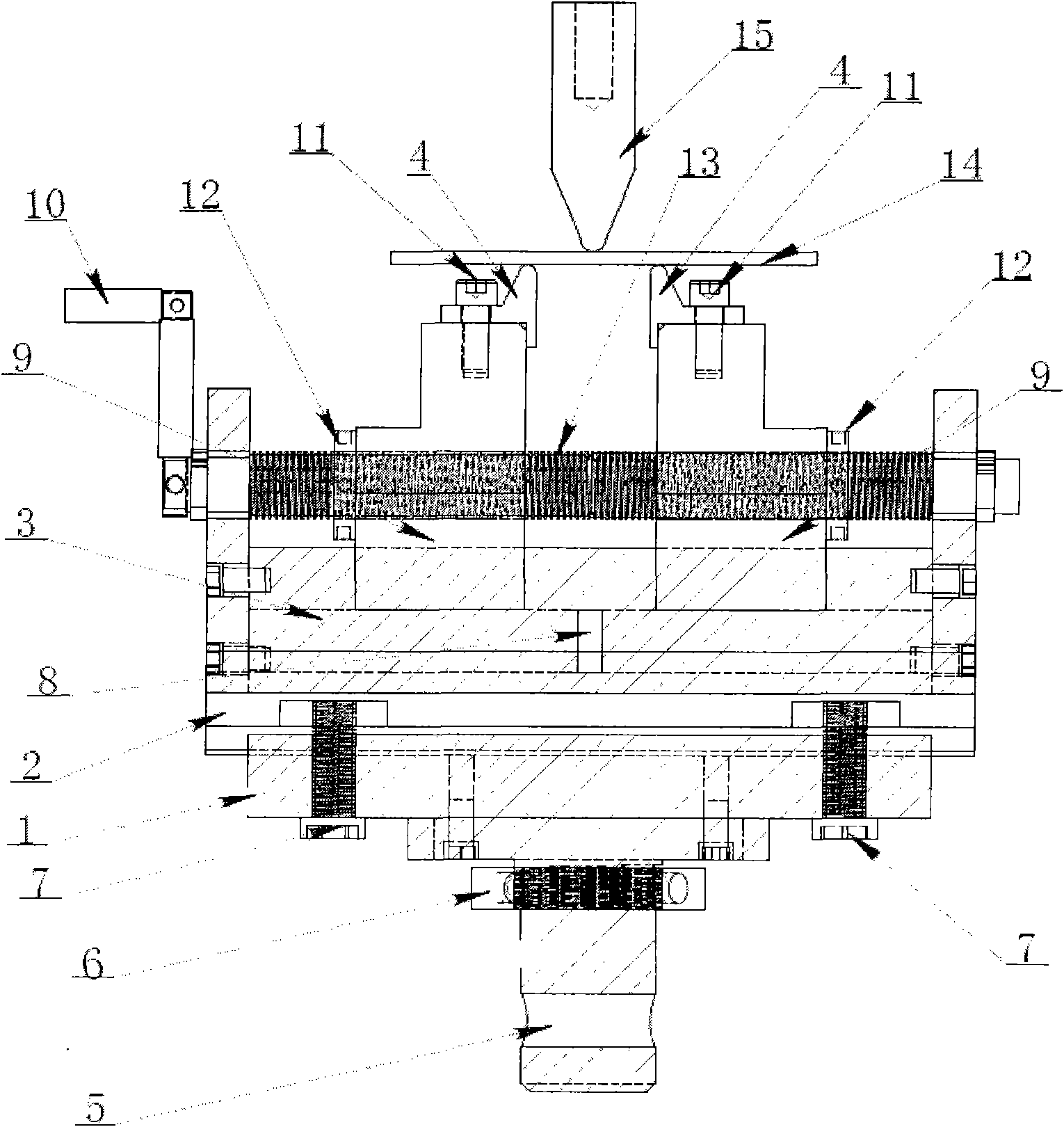

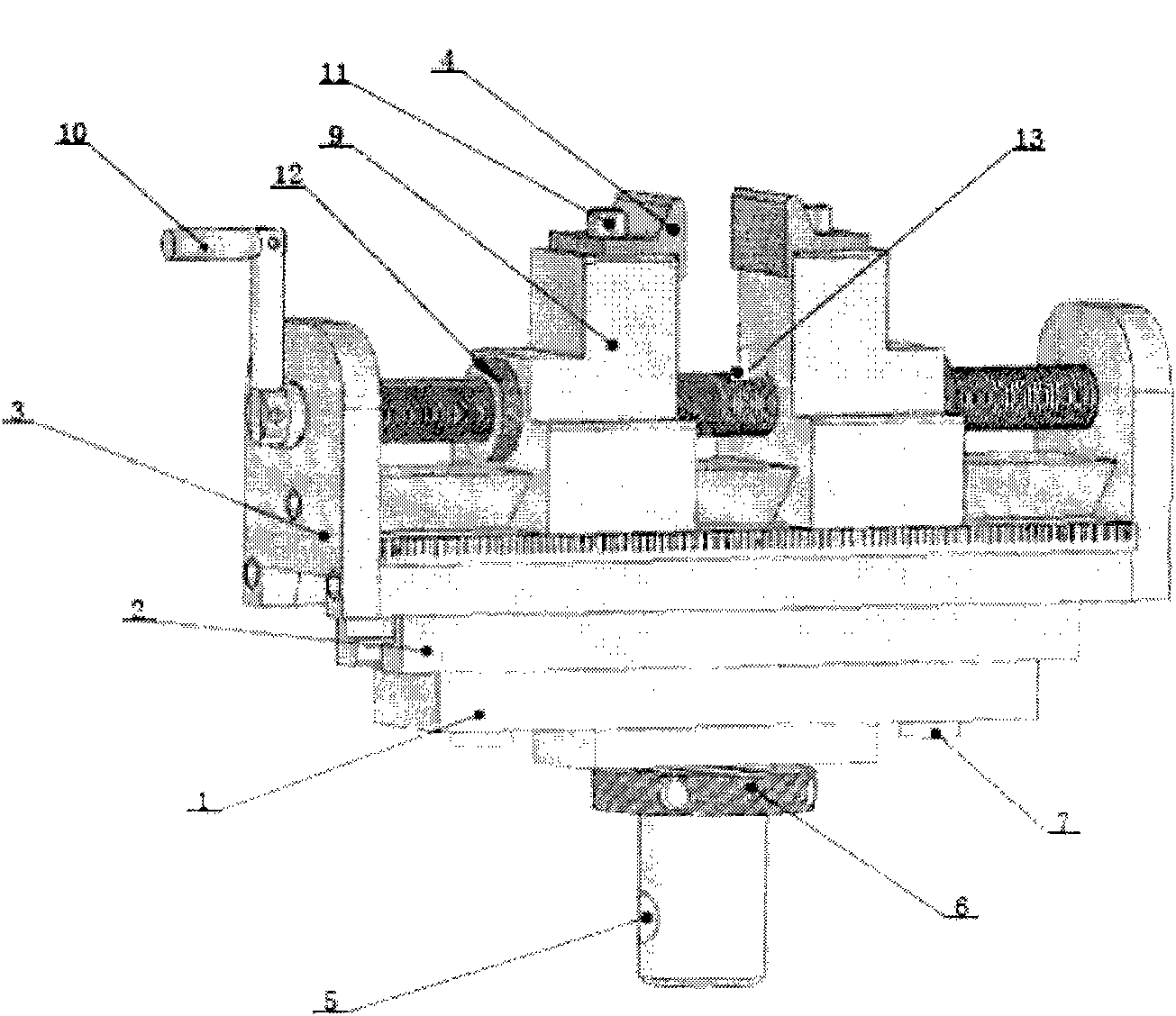

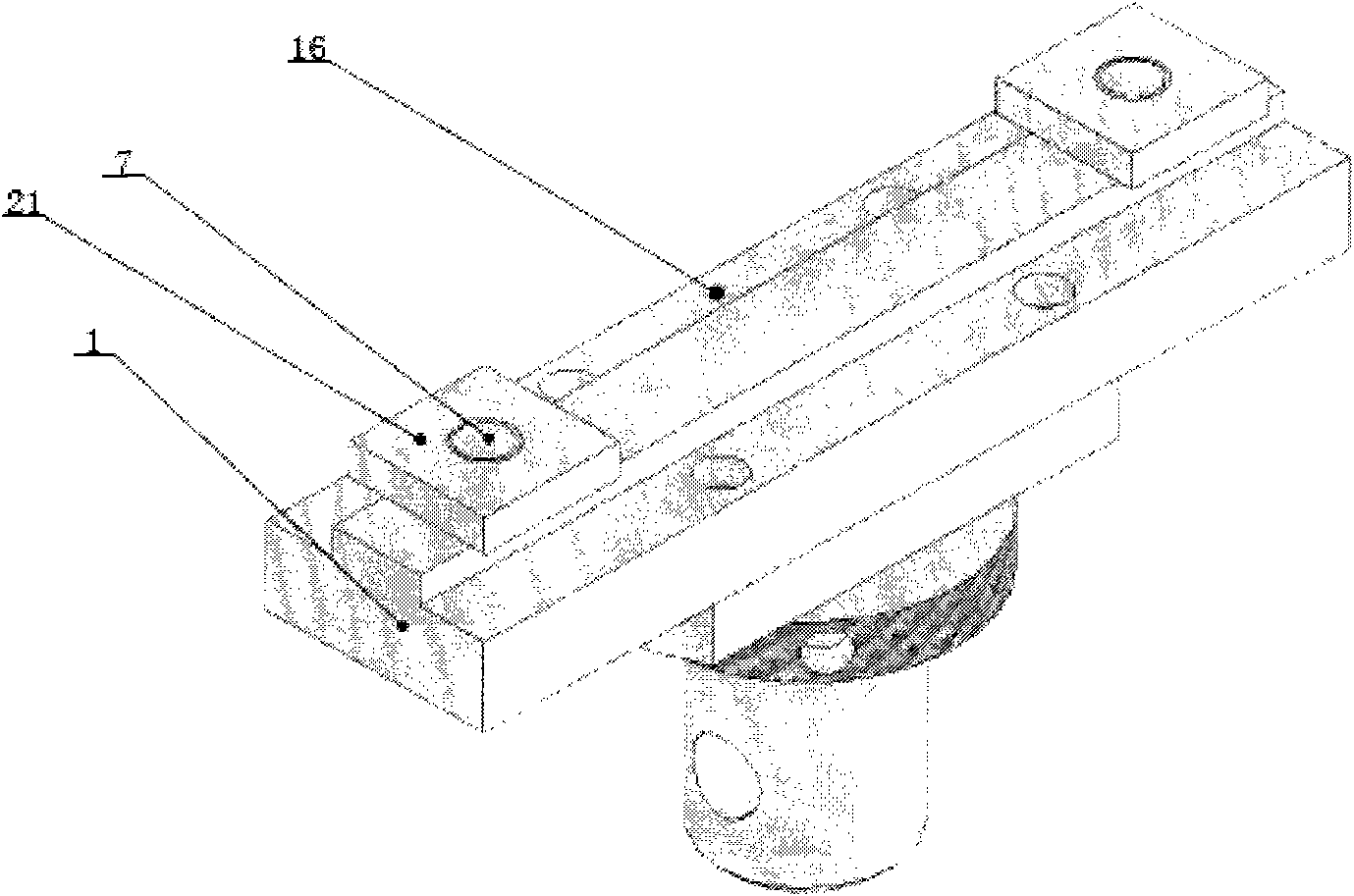

[0015] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

[0016] See attached Figure 1~5 As shown, the fixture for improving the efficiency of bending and interlaminar shear tests of composite materials includes a support device 1 connected to the mechanical performance testing machine and an adjustment platform 2 installed on the support device 1. The bottom of the support device 1 is processed with pins The hole 5 is connected with the connecting rod at the lower end of the testing machine through a pin, and is locked and fixed by a lock nut 6 . The adjustment platform 2 is placed on the slideway 16 with a boss above the support device 1, so that the adjustment platform 2 slides left and right to ensure that the centerline of the pressure head 15 is aligned with the centerline 20 of the adjustment platform, and finally the tension nut 7 is tightened , fixed adjustment platform 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com