Clamp and method for testing pavement interlayer shear fatigue test piece

A pavement interlayer and testing method technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of interlayer shear fatigue without specific regulations, affecting the normal use performance and service life of the pavement, and damage to the base layer. The test method is simple and easy to implement, and the test equipment is simple and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] 1. The large Marshall specimen of asphalt mixture with a diameter of 150mm was prepared by rotary compaction method, and the cement-stabilized macadam specimen with a diameter of 150mm was prepared by compaction method, and the penetrating layer oil and sealing material were applied on the surface of cement-stabilized macadam , and then place the asphalt mixture large Marshall specimen on the cement-stabilized macadam specimen coated with permeable oil, and use a press for static pressure molding, and let the specimen stand for more than 12 hours before proceeding to the next step Experimental operation. The number of samples in the same group shall not be less than 3.

[0042] 2. Place the test piece and the fixture for shear fatigue in a 15°C environment box, and keep the holding time for no less than 6 hours.

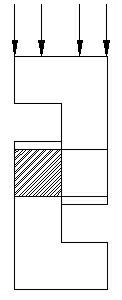

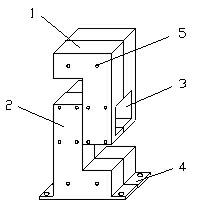

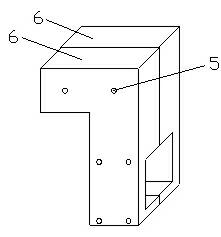

[0043] 3. Put the specimen into the shear fatigue fixture. It should be ensured that the sheared surface of the test piece and the combined surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com