Preparation method and use of nano-SiO2-modified glass fiber film-forming agent emulsion

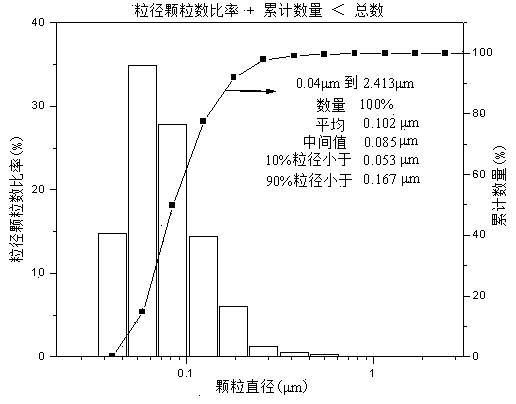

A glass fiber and film-forming agent technology, which is applied in the field of glass fiber film-forming agent emulsion preparation, can solve the problems of cumbersome production process, environmental pollution, less research on organic-inorganic hybrid glass fiber sizing agents, etc. The effect of uniform particle size distribution and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Appropriate amount of nano-SiO 2 The powder was preheated at 100°C for 4h. According to nano-SiO 2 Particles: ethanol: deionized water mass ratio is 1:3:20, weigh nano-SiO 2 Particles, ethanol, deionized water. Weigh the silane coupling agent KH-550, its dosage accounted for 2 4% of the mass, adjust PH=5.0 with glacial acetic acid, ultrasonically disperse at 70°C, 60KHz, 200W for 120min, filter with suction, and wash with ethanol and deionized water 3 times to remove excess unreacted grafted coupling agent. The reaction was dried at 50° C. for 8 hours, and cooled for later use.

[0034] Weigh the nano-SiO modified by KH-550 2 Particles are ultrasonically dispersed in the diluent methyl ethyl ketone, ultrasonic conditions: frequency 70KHz, power 200W, ultrasonic dispersion time 15min. Add the main slurry phenolic epoxy vinyl ester resin V-158 and mixed emulsifier in sequence, and mix evenly under high-speed stirring conditions. Among them, modified nano-SiO 2 Pow...

Embodiment 2

[0056] nano-SiO 2 Powder modification method is the same as Example 1.

[0057] Weigh the nano-SiO modified by KH-550 2 Particles are ultrasonically dispersed in diluent styrene, ultrasonic conditions: frequency 70KHz, power 200W, ultrasonic dispersion time 15min. Add the main slurry unsaturated polyester resin V-196 and mixed emulsifier in sequence, and mix evenly under high-speed stirring conditions. Among them, modified nano-SiO 2 Powder: Emulsifier: The mass ratio of the main slurry is 0.5:8:100, the mass ratio of the diluent styrene to the main slurry is 10:100, and the mixed emulsifier is obtained by mixing SDS and T-80 in a ratio of 25:75 . Stir at a constant speed of 8000r / min for 20min at a high speed, and stir and mix evenly. Slowly add deionized water drop by drop until the mass fraction of the total solid content is 20%, control the rotation speed at 8000r / min, and continue stirring for 30min to obtain a milky white film-forming agent emulsion.

[0058] This ...

Embodiment 3

[0060] nano-SiO 2 Powder modification method is the same as Example 1.

[0061] Weigh the nano-SiO modified by KH-550 2 Particles are ultrasonically dispersed in the diluent n-butanol, ultrasonic conditions: frequency 70KHz, power 200W, ultrasonic dispersion time 15min. Add the main slurry phenolic epoxy vinyl ester resin V-158 and mixed emulsifier in sequence, and mix evenly under high-speed stirring conditions. Among them, modified nano-SiO 2 Powder: Emulsifier: The mass ratio of the main slurry is 3:4:100, the mass ratio of the diluent n-butanol to the main slurry is 20:100, and the mixed emulsifier is a mixture of SDS and EL-20 in a ratio of 50:50 get. Stir at a constant speed of 11000r / min for 20min at a high speed, and stir and mix evenly. Slowly add deionized water drop by drop until the mass fraction of the total solid content is 40%, control the rotation speed at 11000r / min, and continue stirring for 40min to obtain a milky white film-forming agent emulsion.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com