Testing method for interlaminar shearing stress state

A technology of state testing and testing methods, which is applied in the direction of testing the strength of materials by applying a stable shear force to achieve the effect of exquisite structure

Active Publication Date: 2011-03-30

SOUTHEAST UNIV

View PDF4 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although it overcomes the above-mentioned defects of the direct shear tester, the shear strength obtained from this test is only the shear strength of the bond between materials under the condition of no friction between the layers, and under the actual road conditions, the vehicle has no friction with the road surface. The shearing process is often accompanied by interlayer friction

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

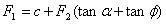

The invention relates to a testing method for the interlaminar shearing stress state, which is a method for evaluating the shearing strength between a cement concrete deck and an asphalt pavement layer. The method can simultaneously acquire the cohesive force C and the friction angle between interfaces by testing once, and is a reasonable testing method for the shearing strength between the cement concrete deck and the asphalt pavement layer. The testing method comprises the following steps: (a) an inclined plane with an inclined angle of 5 degrees-30 degrees, namely a rigid triangular block (8), is arranged in a direction vertical to load application (4); a horizontal force-measuring device (5) is positioned behind the rigid triangular block (8); a loading specimen (1) and a fixed specimen (3) are positioned in a clamp (10); the load vertically applied to the loading specimen (1) is converted into a horizontally applied force to realize application of positive pressure on a shearing interface (2); (b) bearing balls (9) are arranged on the inclined plane to eliminate the effect of the frictional force on the inclined plane to the test result; and (c) based on the testing method, the cohesive force and the friction angle between the interfaces are acquired by calculating with a calculation formula as shown in the specification.

Description

technical field The invention relates to a method for evaluating the shear strength between a cement concrete bridge deck and an asphalt pavement layer, and belongs to the technical field of highway pavement performance testing. Background technique In the process of bridge construction in our country, cement concrete bridges have been widely used. At present, asphalt concrete is widely used as the pavement material on cement concrete bridge decks, thus forming the asphalt concrete pavement layer of concrete bridges. In order to make the multi-layer system composed of cement concrete and asphalt concrete have good structural bearing capacity and durability, the treatment technology between bridge pavement layers and the detection technology of various indicators have attracted more and more attention. It is one of the problems that have been puzzling the bridge and road workers all the time to determine the appropriate test method for the shear strength between the bridge c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/24

Inventor 赵永利侯中新

Owner SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com