Sizing agent for emulsion type carbon filter and preparation method and application thereof

An emulsion-type carbon fiber and carbon fiber technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problem of low interlayer shear strength and achieve the effect of improved interlayer shear strength and high overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

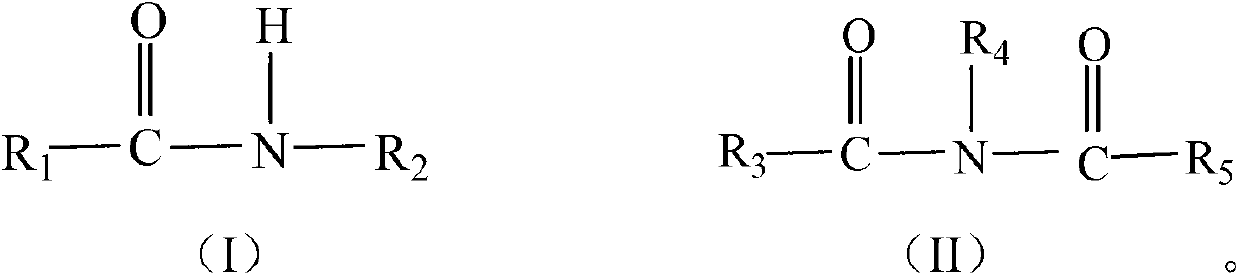

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An emulsion type carbon fiber sizing agent is prepared by the following steps:

[0037] Add 0.5g of surfactant (Japan Emulsifier Company / Nikon 707-SF) into 96.5g of deionized water, stir properly to mix evenly; then add 2g of bisphenol A epoxy resin and 1g of formamide , stirring at 1000r / min at 40°C for 100min; then high-speed shear emulsification at 10,000r / min at 40°C for 35min; finally stirring at 1000r / min at 40°C for 25min to obtain the emulsion carbon fiber Use sizing agent.

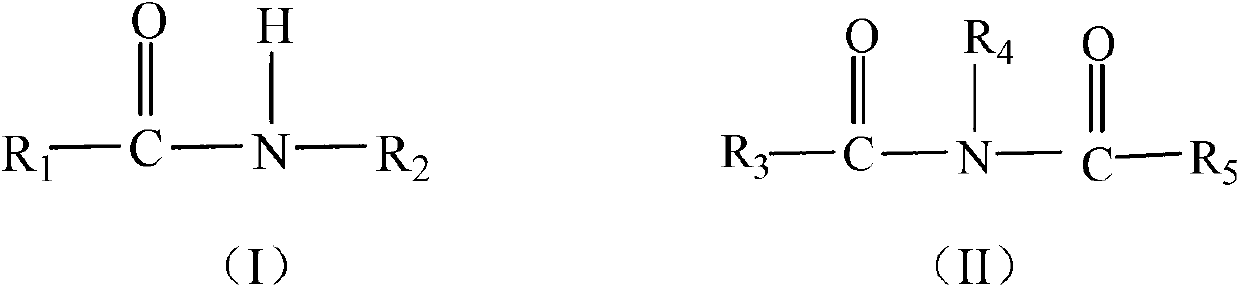

[0038] The structure of a surfactant is shown below:

[0039]

[0040] Nippon Emulsifier Company / Nikon 707-SF

Embodiment 2

[0042] An emulsion type carbon fiber sizing agent is prepared by the following steps:

[0043] (1) Add 2.5g of diphenyl sulfone into 2.5g of ethanol, stir properly at 40°C to dissolve it for later use;

[0044] (2) Add 1.5g of surfactant (0.75g Mitsubishi Rayon Company / BPEO20SON, 0.75g Mitsubishi Rayon Company / SPEO120SON) into 91g of deionized water, stir properly to mix evenly; then add 5g of bisphenol F Type epoxy resin, 2.5g of glutarimide, stirred at 60°C at a speed of 750r / min for 80min; Stir at a speed of 750r / min for 20min to obtain a sizing agent for emulsion carbon fiber.

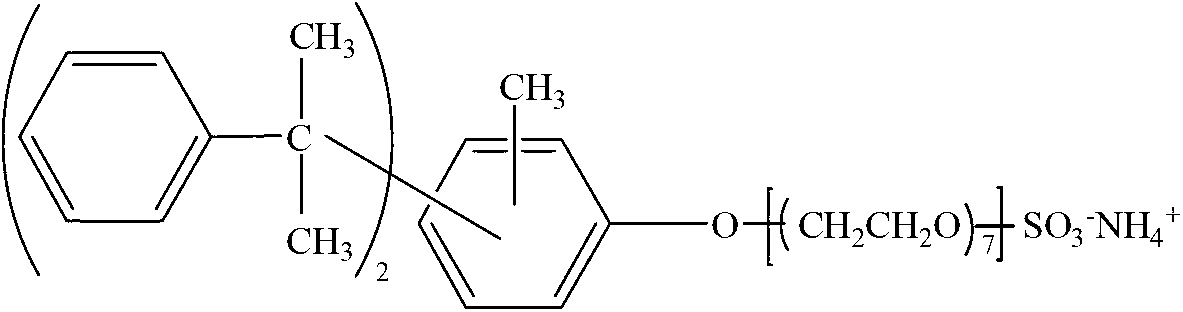

[0045] The structure of a surfactant is shown below:

[0046]

[0047] Mitsubishi Rayon Corporation / BPEO20SON

[0048]

[0049] Mitsubishi Rayon Corporation / SPEO120SON

Embodiment 3

[0051] An emulsion type carbon fiber sizing agent is prepared by the following steps:

[0052] (1) Add 2.5g of diphenyl sulfone into 2.5g of ethanol, stir properly at 40°C to dissolve it for later use;

[0053] (2) Add 3.5g of surfactant (1.5g of polyoxyethylene alkyl ether, 2.0g of polyoxyethylene alkylphenyl ether) into 81.5g of deionized water, stir properly to mix evenly; then add 10g of phenolic Epoxy resin, 5g modifier (2.5g formamide, 2.5g glutarimide), stirred at 500r / min at 60°C for 60min; then sheared at 5000r / min at 60°C Cut and emulsify for 15 minutes; finally stir at 60°C at a speed of 500r / min for 15 minutes to obtain an emulsion-type carbon fiber sizing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com