Reinforcement method for continuous filament reinforced metallic matrix composite

A composite material and continuous fiber technology, applied in the field of reinforcement of composite materials, can solve the problems of easy delamination, low stiffness and strength performance, low impact toughness and damage tolerance level, so as to improve interlayer strength and prevent delamination. Effect of layer cracking and shear failure, strengthening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

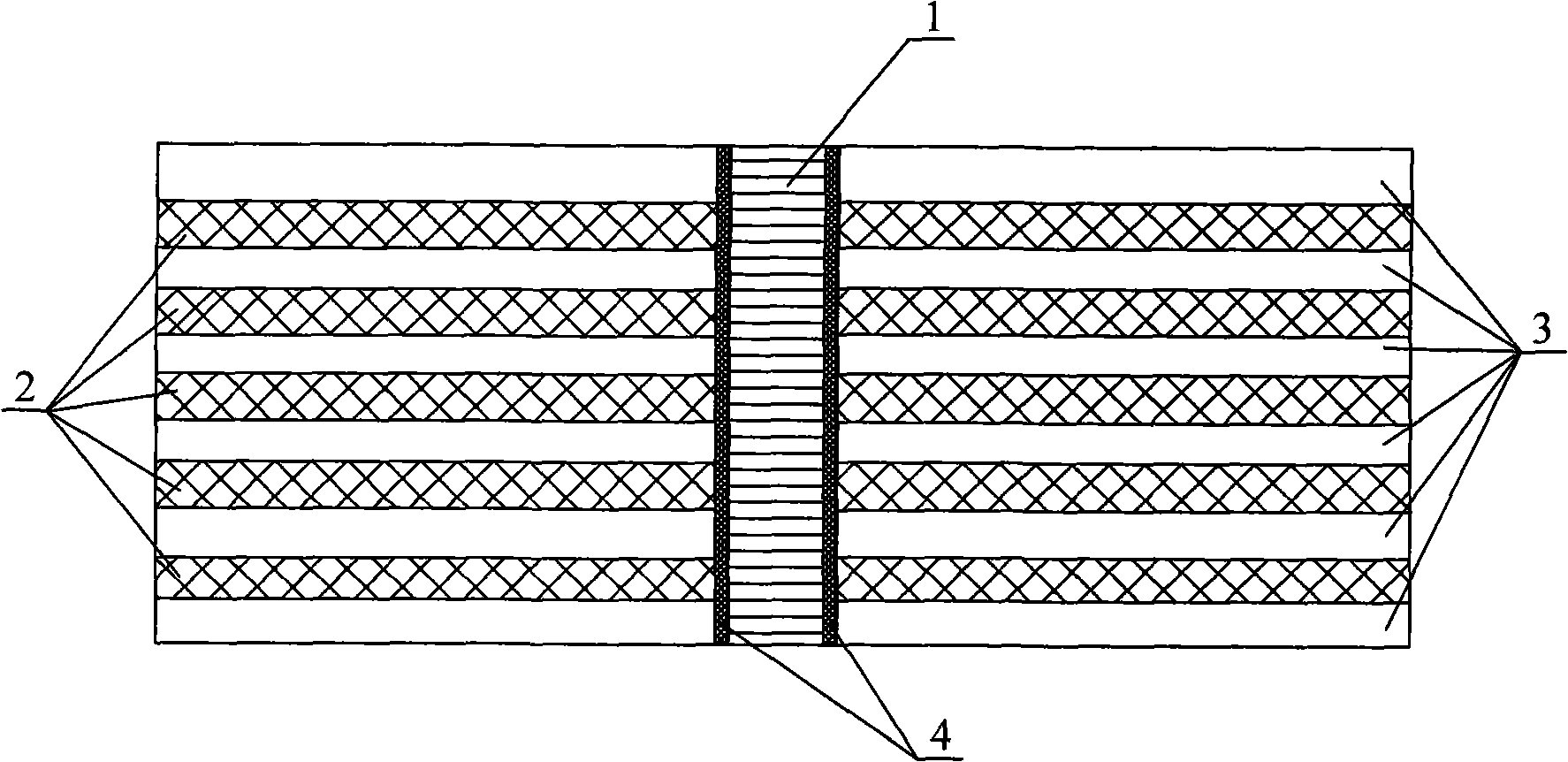

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, the method of this embodiment is realized as follows: After the fiber preform 2 is prepared, add the metal wire 1 to the fiber preform 2, and the fiber preform 2 and the composite material matrix 3 are heated for metal liquid immersion After cooling, the reinforcement of continuous fiber reinforced metal matrix composites is completed. This design enables the high-strength metal wire 1 to form a strong interfacial bond with the composite material matrix 3, which improves the performance of the fiber-reinforced metal matrix composite material in the direction of weakness such as thickness or interlayer. Due to the high rigidity of the metal wire 1, it can be manually inserted into the fiber preform, and at the same time, the dense fiber arrangement in the fiber preform can make the metal wire fixed in the fiber preform without falling off; the process method operates It is simple, does not requ...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 The present embodiment will be described. In this embodiment, the wire 1 is inserted in the thickness direction of the fiber preform 2 . This design makes the metal wire 1 and the composite material matrix 3 form a strong interfacial bond, which improves the performance of the fiber-reinforced metal matrix composite material in the direction of weakness such as thickness or interlayer. Since the metal wire 1 has high rigidity, it can be manually inserted into the fiber preform, and at the same time, the dense fiber arrangement in the fiber preform allows the metal wire to be fixed in the fiber preform without falling off.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 The present embodiment will be described. The metal wire 1 of the present embodiment is inserted in the vertical direction between the fiber layers of the fiber preform. Utilizing the physical characteristics of the high strength of the metal wire itself and the strong interfacial bonding with the composite material matrix, the metal wire is "nailed" in the vertical (weak) direction between the fiber layers of the metal matrix composite material like a "nail". After the two-dimensional laying of fiber prefabricated parts, it is directly inserted in the vertical direction of the layup, because in the subsequent metal liquid infiltration process, the metal wire will have an interface reaction with the liquid matrix metal to form a certain thickness of the interface reaction layer 4. It leads to a proper bonding force between the metal wire and the matrix, and at the same time, the high strength of the metal wire eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com