Preparation method of high-quality copper-zinc-tin sulphur semiconductor film

A copper-zinc-tin-sulfur semiconductor technology, which is applied in the field of preparation of high-quality copper-zinc-tin-sulfur semiconductor thin films, can solve problems such as high vulcanization temperature, long vulcanization time, and affecting film quality, and achieve high purity, fast film formation rate, The effect of increasing conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

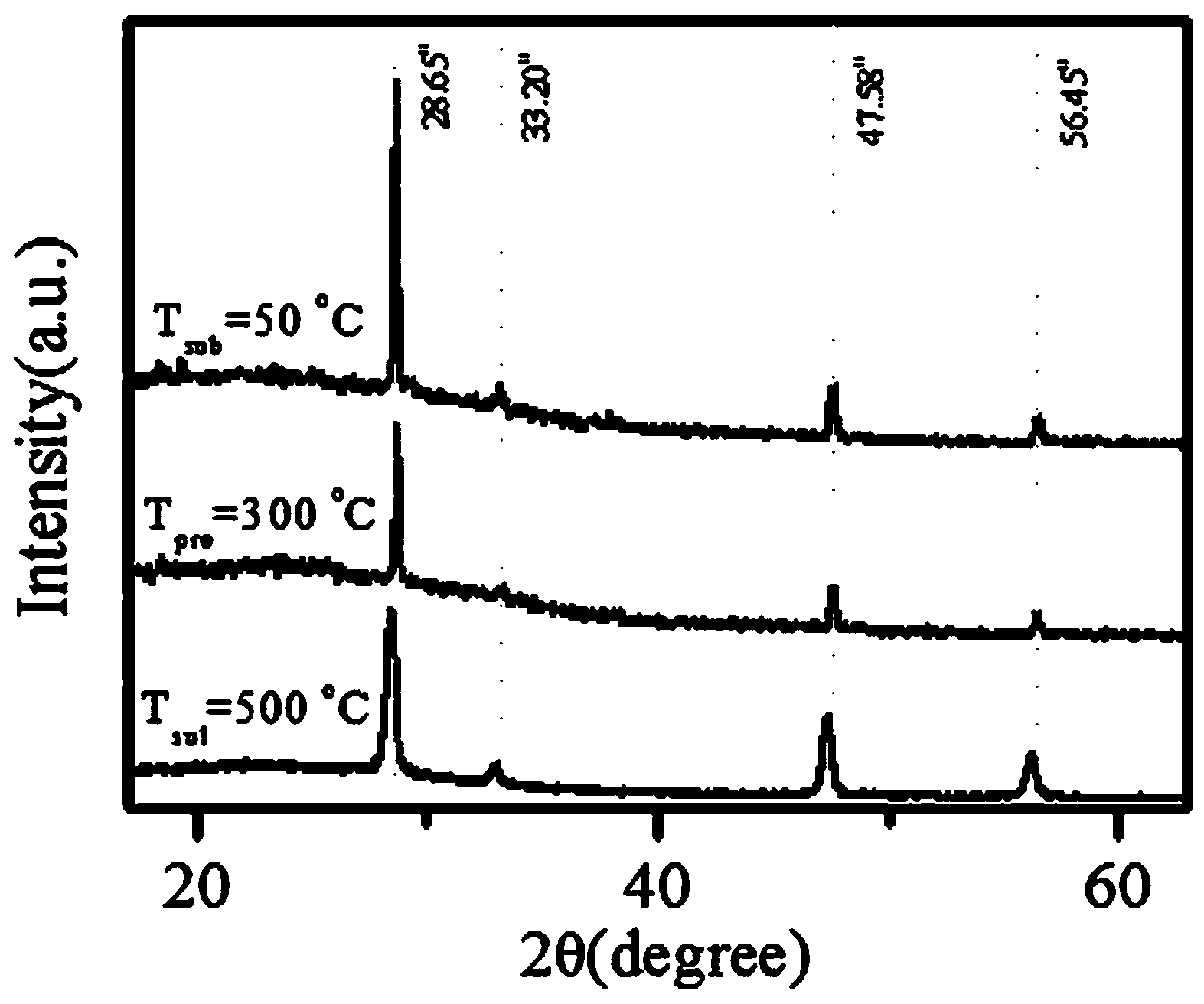

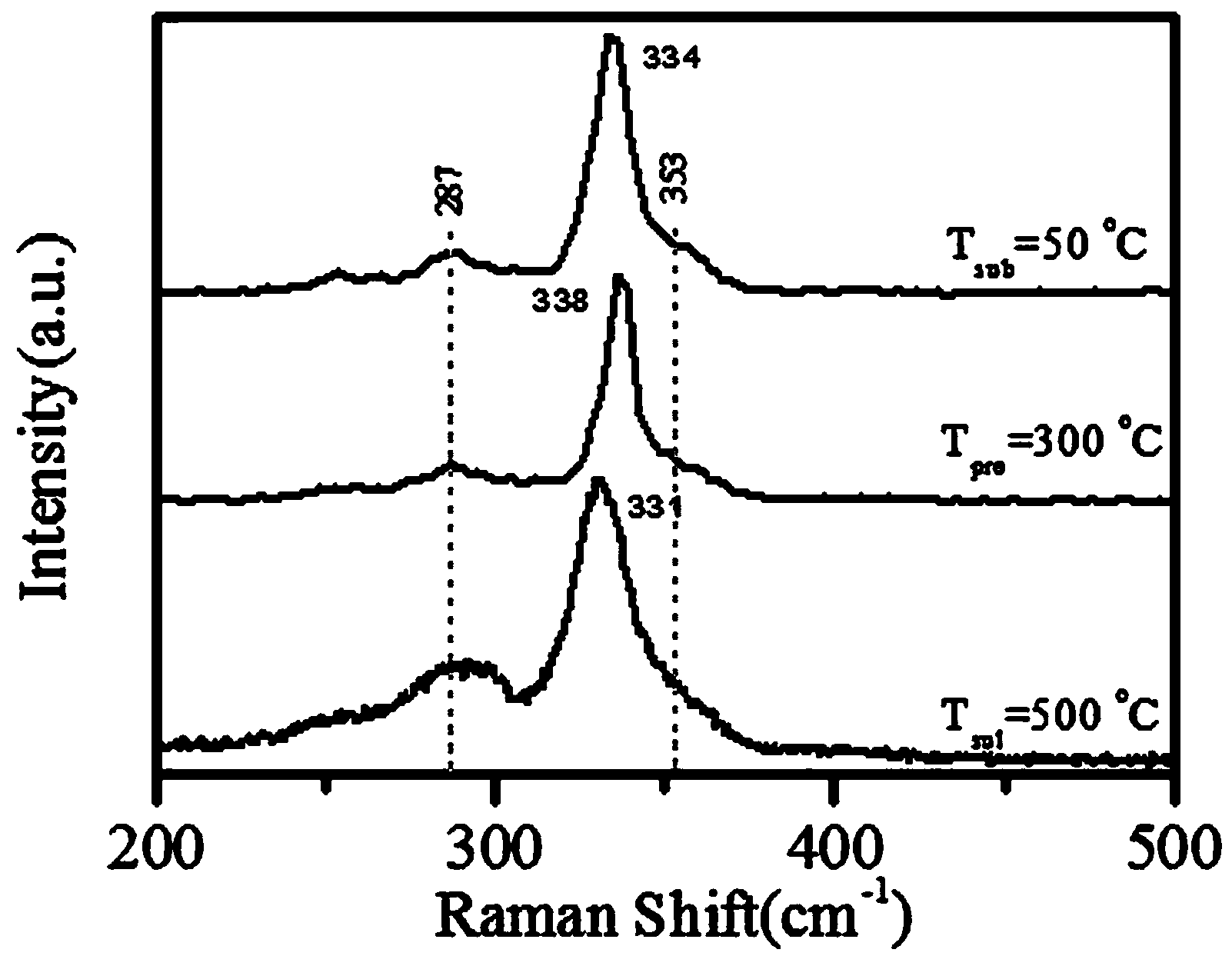

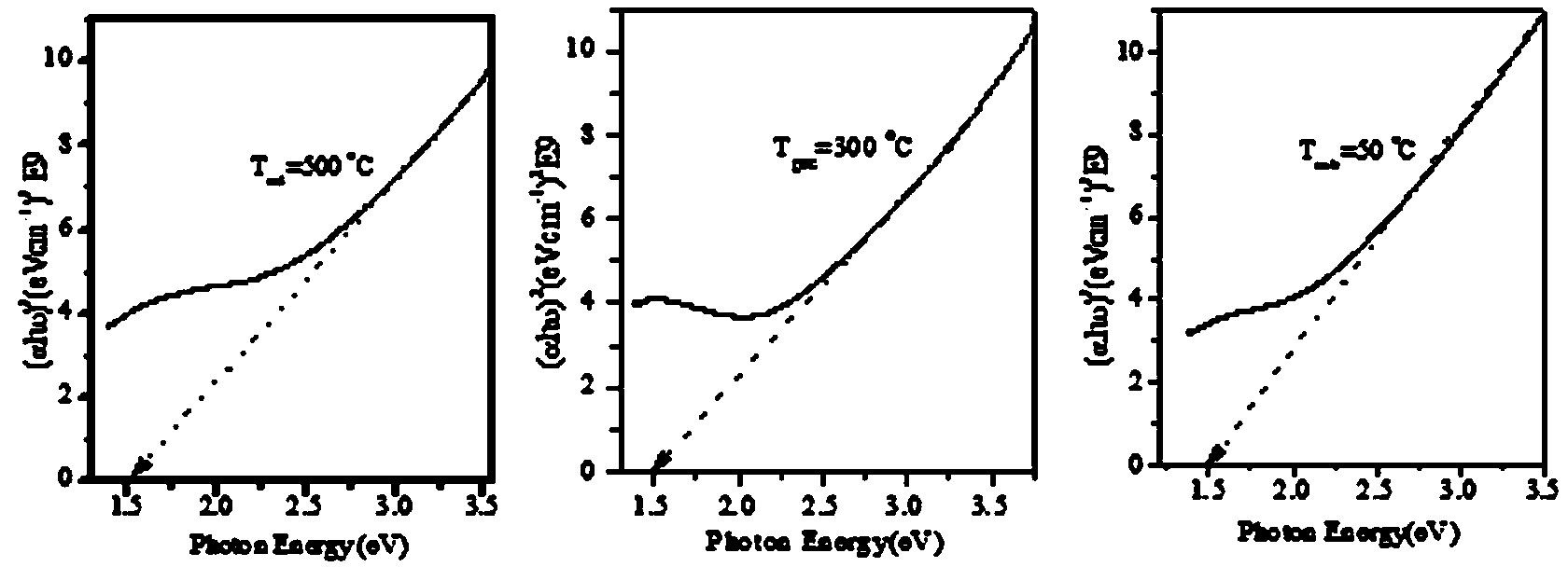

Embodiment 1

[0031] Put copper, zinc and tin with a molar ratio of 2:1:1 in three tungsten boats respectively, and place them in the vacuum chamber of a vacuum coating machine. Take the cleaned glass substrate and heat it to 50°C. According to the Cu-Zn- The sequential evaporation of Sn is complete to obtain the metal thin film precursor. Put the metal thin film precursor and a sufficient amount of high-purity sulfur powder in a tube furnace, heat it under the protection of nitrogen, first raise the temperature to 400 °C at a rate of 5 °C / min, and then keep it for 1 hour, and finally obtain a thickness of about 1.5 μm CuZnSnS semiconductor film.

Embodiment 2

[0033] Put copper, zinc and tin with a molar ratio of 5:3:2 in three tungsten boats respectively, and place them in the vacuum chamber of a vacuum coating machine. Take the cleaned silicon substrate and heat it to 20°C. According to the Sn-Zn -The sequential evaporation of Cu is complete to obtain the metal thin film precursor. Put the metal film precursor and a sufficient amount of high-purity sulfur powder in a tube furnace, heat it under the protection of argon, first raise the temperature to 200°C at a rate of 5°C / min, and then keep it for 2 hours. 1.6μm CuZnSnS semiconductor film.

Embodiment 3

[0035] Put copper, zinc and tin with a molar ratio of 3:2:2 in three molybdenum boats respectively, and place them in the vacuum chamber of a vacuum coating machine. Take the cleaned stainless steel substrate and heat it to 200°C. According to the Zn-Sn -The sequential evaporation of Cu is complete to obtain the metal thin film precursor. Put the metal film precursor and a sufficient amount of high-purity sulfur powder in a tube furnace, evacuate the tube furnace, and heat it up to 300 °C at a rate of 5 °C / min, then keep it warm for 0.5 h, and finally A copper-zinc-tin-sulfur semiconductor thin film with a thickness of about 1.4 μm was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com