Butadiene-acrylonitrile rubber used in low-temperature vulcanized high-performance screw pump stator and preparation method thereof

A low-temperature vulcanization technology for nitrile rubber, which is applied in the chemical industry, climate sustainability, sustainable manufacturing/processing, etc., can solve problems such as high vulcanization temperature, easy aggregation and growth of nanoparticles, loss of nano-performance, etc., to achieve improved Oil swelling and aging resistance, broadened application range, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the above-mentioned low-temperature vulcanization high-performance screw pump stator is characterized in that: the method steps are as follows:

[0029] (1) Weigh the materials according to the above ratio for later use; adjust the roll distance of the open mill to 0.5-1mm, weigh the nitrile rubber and put it into Botong plastication for 3 minutes and cover the rolls.

[0030] (2) Add the compounding ingredients to the open mill for mixing in turn; the order of feeding is: nitrile rubber→sulfur→stearic acid→nanometer zinc oxide→γ-aminopropyltriethoxysilane→4010 anti-aging agent→N330 high Wear-resistant carbon black → dioctyl phthalate (DOP) → DM+TMTD+MgO, use the triangular bag method to pack 8-10 times to make it evenly mixed.

[0031] (3) After the obtained mixed rubber is left for 24 hours, it is re-milled for 3-5 minutes, and the vulcanization temperature is changed to measure the vulcanization time; according to the vulcanization temperatu...

Embodiment 1

[0035] According to the ratio of parts by mass, it consists of the following raw materials: 100 parts of nitrile rubber, 60 parts of high wear-resistant carbon black, 5 parts of nano-zinc oxide, 2 parts of γ-aminopropyl triethoxysilane (KH550), 1 part of stearic acid 1 part, 1 part of 4010 anti-aging agent, 1.5 parts of vulcanizing agent, 2.5 parts of DM, 0.25 parts of TMTD, 0.15 parts of MgO, 2 parts of dioctyl phthalate (DOP).

[0036] The above-mentioned preparation method of nitrile rubber for high-performance screw pump stator with low-temperature vulcanization, the steps are as follows: take the material according to the above ratio for use; 3 minutes and cover the rolls; add the compounding ingredients in turn to the open mill for mixing. The feeding sequence is: nitrile rubber → sulfur → stearic acid → nano-zinc oxide → γ-aminopropyltriethoxysilane → 4010 anti-aging agent → N330 high wear-resistant carbon black → dioctyl phthalate (DOP) → DM+TMTD+MgO, use the triangul...

Embodiment 2

[0040] The above-mentioned parts by mass are the same as in Example 1, and will not be repeated here.

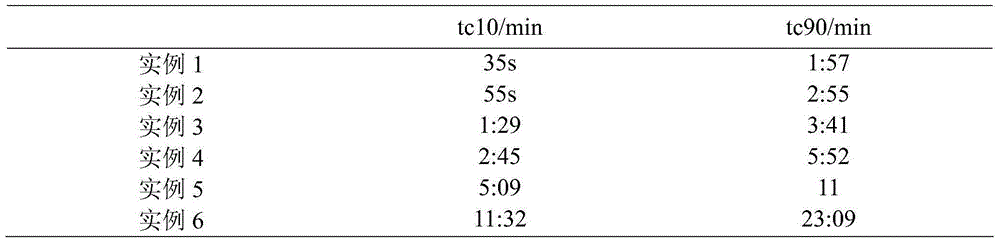

[0041] The mixing process in the preparation method is the same as that in Example 1, and will not be repeated here. After leaving the obtained mixed rubber for 24 hours, re-mill for 3-5 minutes, fix the vulcanization temperature at 140°C, and measure the vulcanization time tc 90 ;according to the obtained tc 90 , vulcanize the compound rubber in a flat vulcanizing machine.

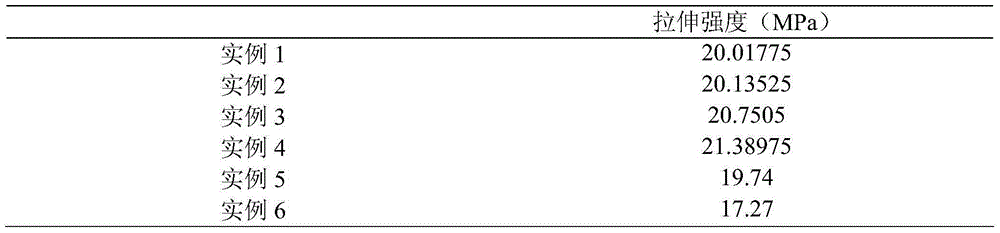

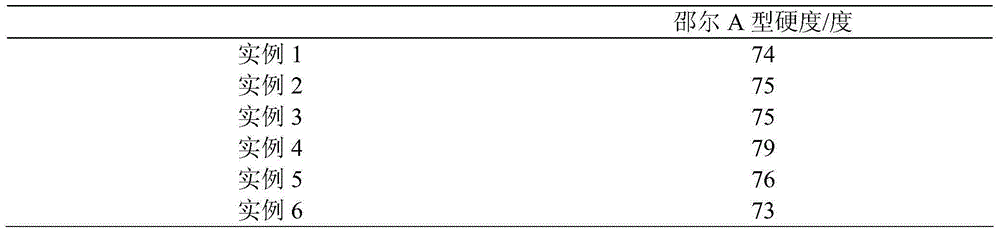

[0042] Table 1 shows the mechanical property test results of the low-temperature vulcanized high-performance screw pump stator nitrile rubber obtained in this example, see Table 2 for the hardness test results, see Table 3 for the vulcanization time test results, and see Table 4 for the swelling resistance test results. The wear test is shown in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com