Low smell EPDM for automobile wire harness and preparation method thereof

A low-odor, automotive-line technology, applied in the field of key automotive parts, can solve problems such as not being able to meet the odor requirements of SAIC GM, and achieve the effects of improving process performance and physical and mechanical properties, fast vulcanization speed, and lower vulcanization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

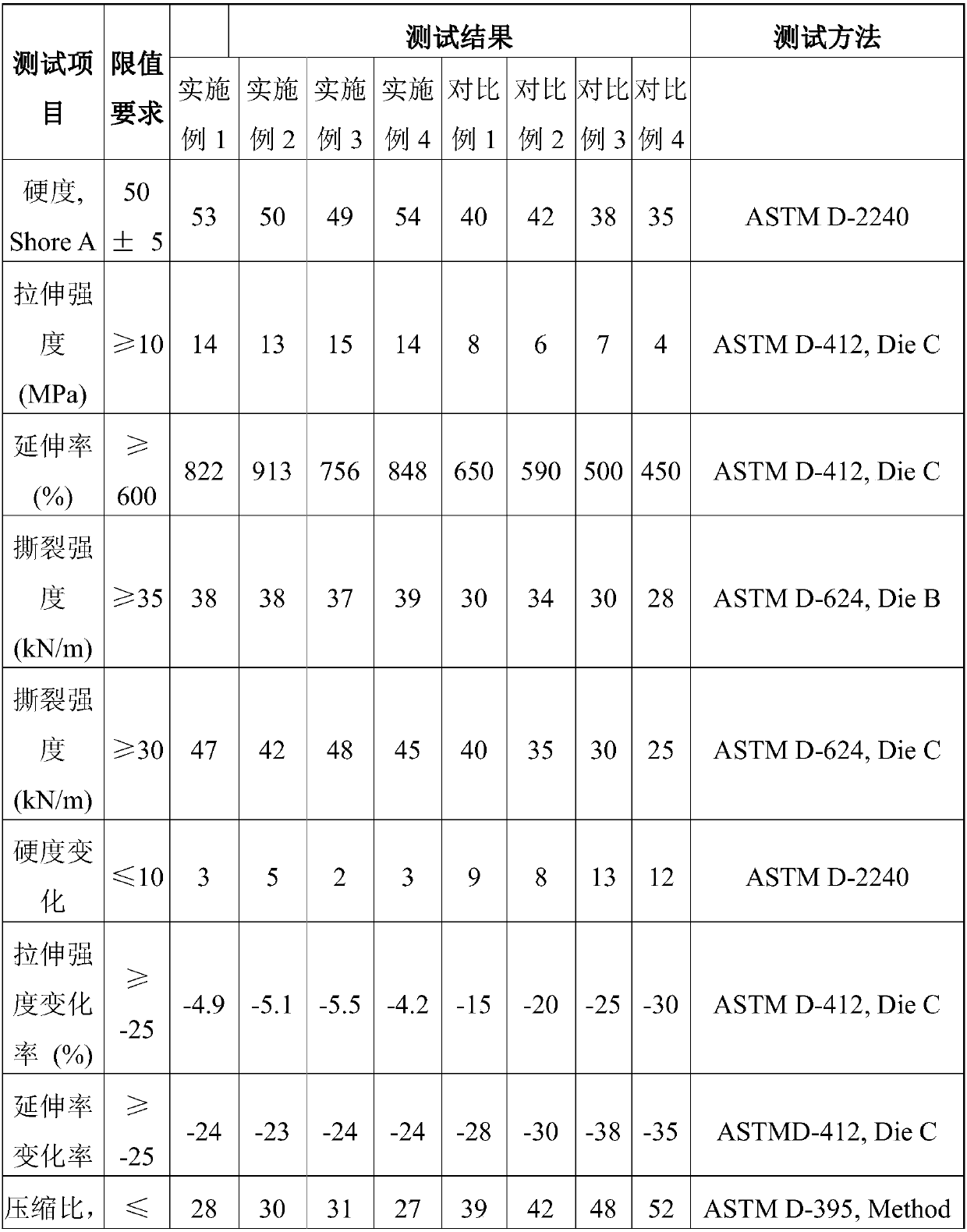

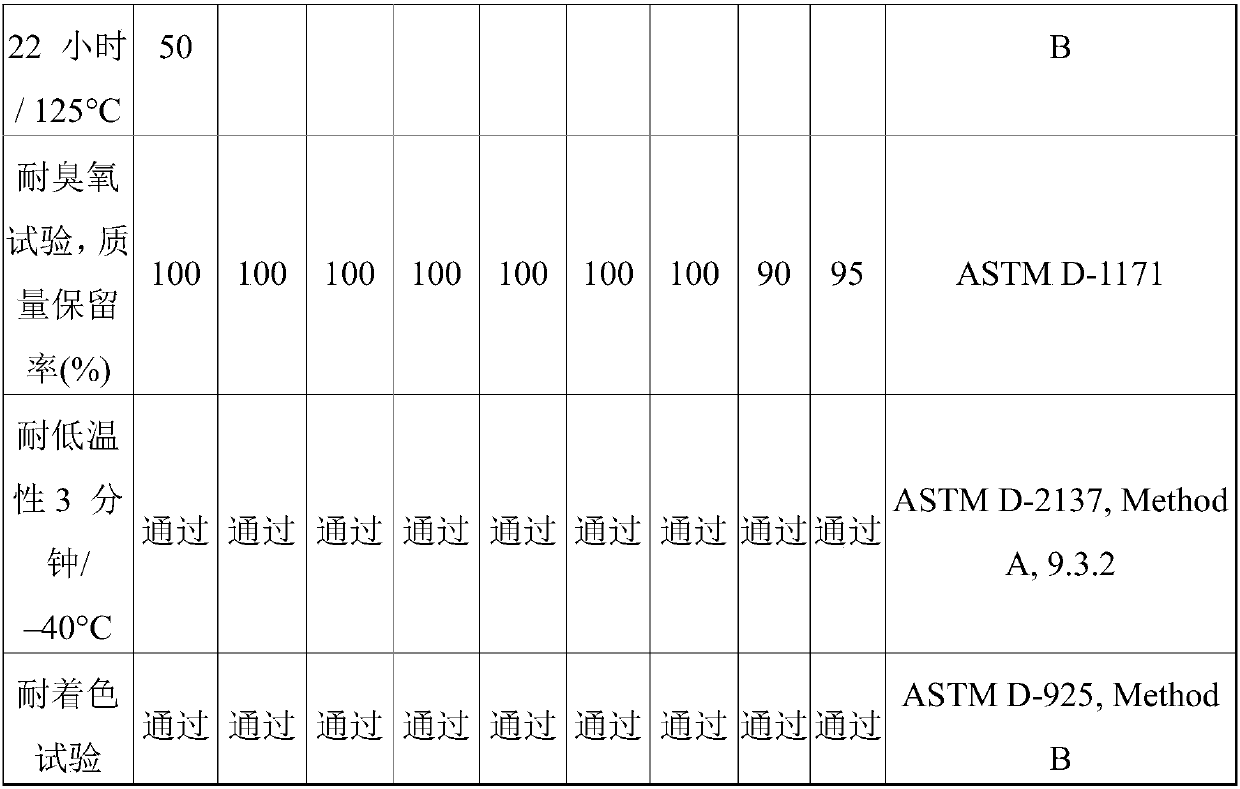

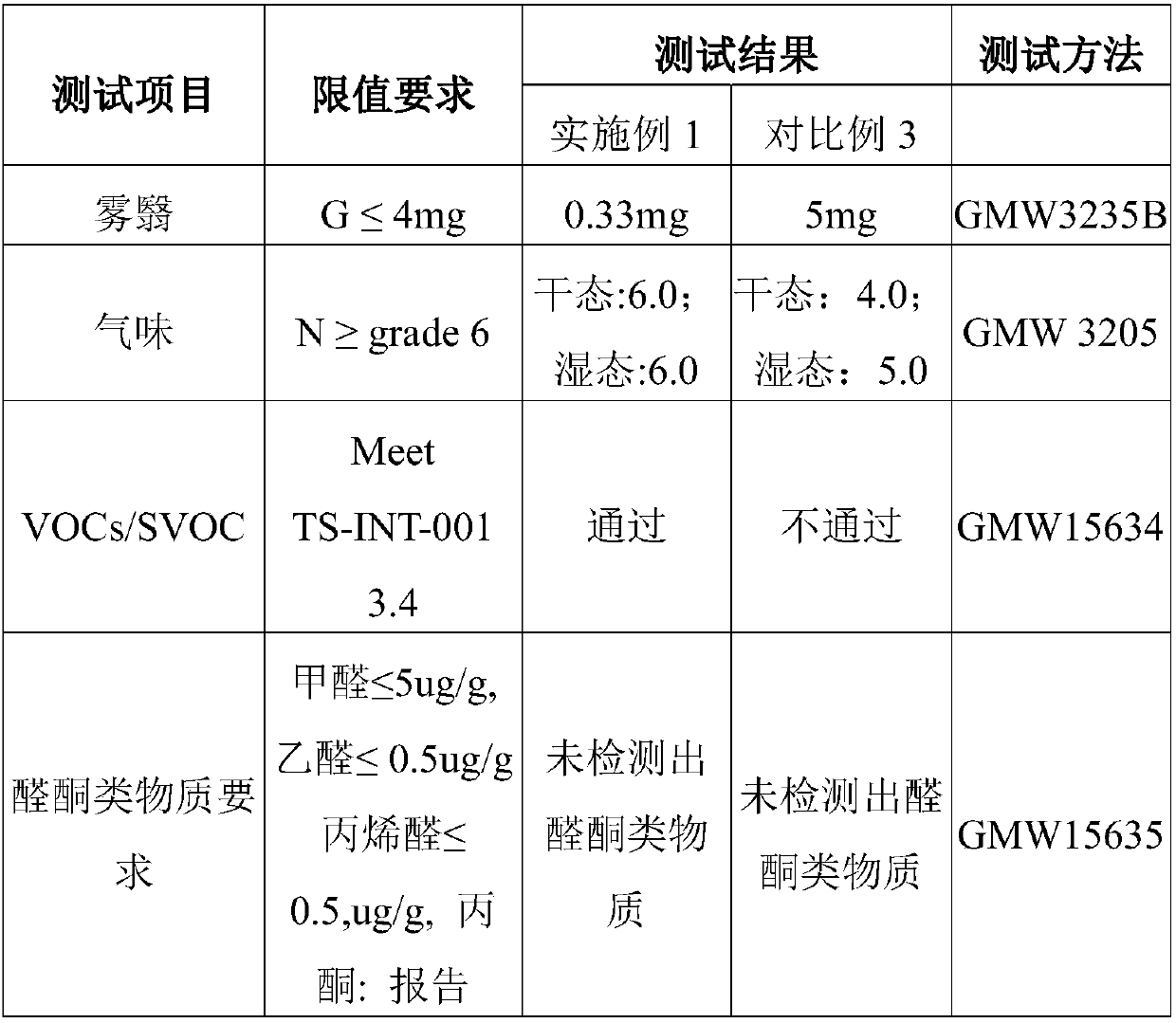

Examples

Embodiment 1

[0023] A preparation method of low-odor EPDM rubber for automobile wiring harness, comprising the following steps:

[0024] (1) First put 90 parts of EPDM rubber into the open mill, then put in 2.5 parts of zinc oxide, 0.8 parts of stearic acid and 1.5 parts of anti-aging agent RD in turn, mix evenly, and then continue to put in 70 parts of carbon black (carbon black Black N550 and carbon black N770 are mixed in a ratio of 3:1) and 60 parts of paraffin oil 2280, after mixing evenly, finally put in 1 part of environment-friendly accelerator PFD and 0.5 part of sulfur, and knead to obtain a rubber compound;

[0025] (2) Put the mixed rubber in the mold for primary vulcanization, the temperature is 178°C, the vulcanization time is 480s, and the vulcanization pressure is 195kg / cm 2 , obtain one section of vulcanized EPDM rubber;

[0026] (3) Take out a section of vulcanized EPDM rubber and send it into an oven for secondary vulcanization. The temperature of the secondary vulcaniz...

Embodiment 2

[0028] A preparation method of low-odor EPDM rubber for automobile wiring harness, comprising the following steps:

[0029] (1) First put 110 parts of EPDM rubber into the mill, then put in 4.5 parts of zinc oxide, 1.2 parts of stearic acid and 2.5 parts of anti-aging agent RD in turn, mix evenly, and then continue to put in 110 parts of carbon black (carbon Black N550 and carbon black N770 are mixed in a ratio of 3:1) and paraffin oil 2280 90 parts, after mixing evenly, finally drop into 1.5 parts of environment-friendly accelerator PFD and 1.0 part of sulfur, and mix to obtain rubber compound;

[0030] (2) The mixed rubber is placed in a mold for primary vulcanization, the temperature is 185° C., the vulcanization time is 300 s, and the vulcanization pressure is 190 kg / cm2 to obtain a section of vulcanized EPDM rubber;

[0031] (3) Take out a section of vulcanized EPDM rubber and send it into an oven for secondary vulcanization. The temperature of the secondary vulcanization...

Embodiment 3

[0033] A preparation method of low-odor EPDM rubber for automobile wiring harness, comprising the following steps:

[0034] (1) First put 100 parts of EPDM rubber into the open mill, then put in 3 parts of zinc oxide, 1 part of stearic acid and 2 parts of anti-aging agent RD in turn, mix evenly, and then continue to put in 90 parts of carbon black (carbon Black N550 and carbon black N770 are mixed in a ratio of 3:1) and paraffin oil 2280 75 parts, after mixing evenly, finally drop into 0.9 part of environment-friendly accelerator PFD and 0.6 part of sulfur, and mix to obtain rubber compound;

[0035] (2) Put the mixed rubber in the mold for primary vulcanization, the temperature is 180°C, the vulcanization time is 420s, and the vulcanization pressure is 190kg / cm 2 , obtain one section of vulcanized EPDM rubber;

[0036] (3) Take out a section of vulcanized EPDM rubber and send it into an oven for secondary vulcanization. The temperature of the secondary vulcanization is 125° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com