Epoxidized natural rubber composite material with self-repairing function and preparation method thereof

A technology of natural rubber and composite materials, which is applied in the field of epoxidized natural rubber composite materials and its preparation, can solve the problems of poor thermal stability and low strength of hydrogen bonds, and achieve improved stability, increased strength, and enhanced hydrogen bond network Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

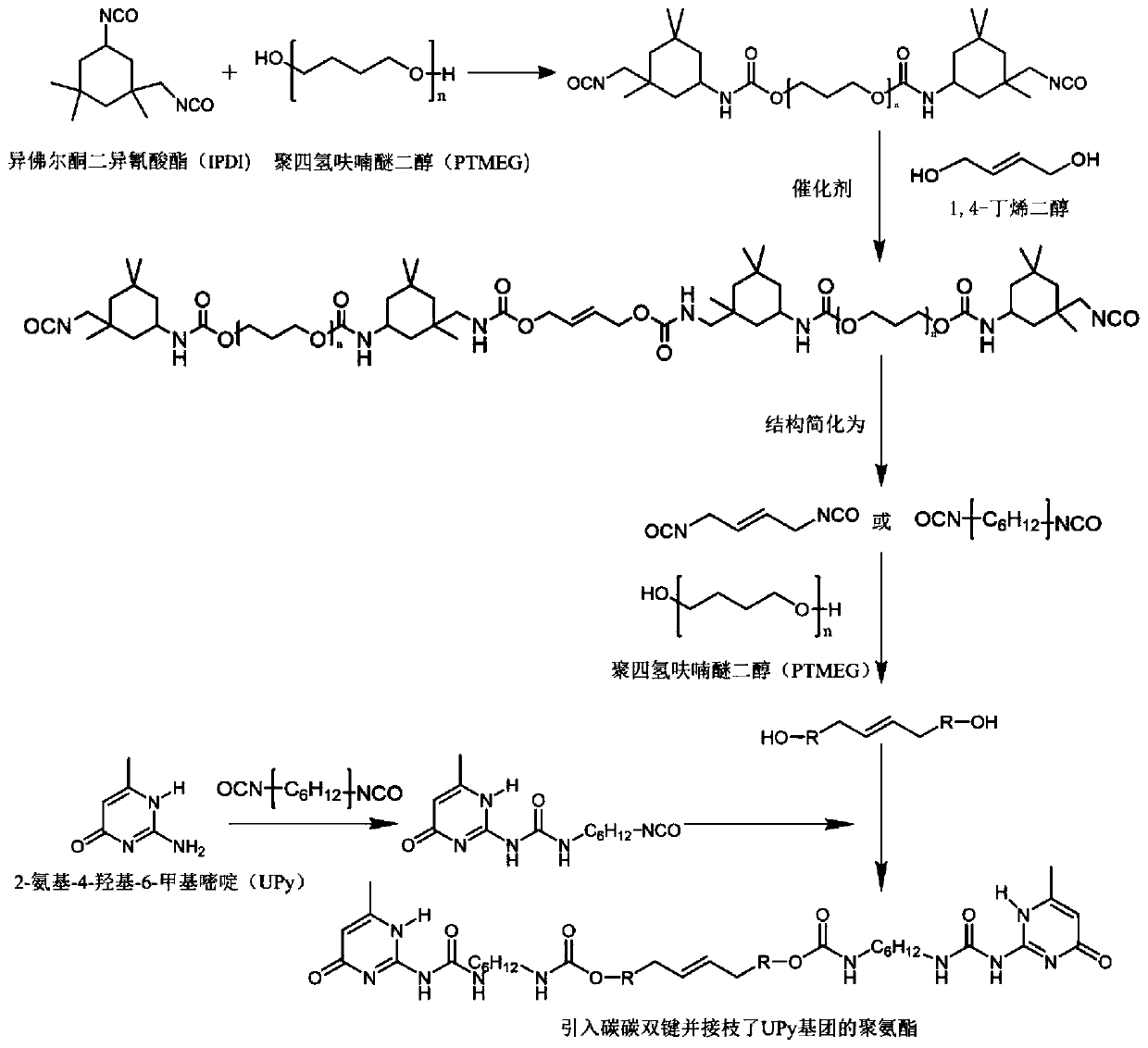

[0041] Example 1: Synthesis of polyurethane (PU) with carbon-carbon double bond introduced:

[0042] (1) Mix 0.1 mol of IPDI with 0.05 mol of PTMEG-1000, add 30 ml of DMAC as a solvent, and react under reflux at 80°C for 2 hours. .

[0043] (2) After the reaction is over, lower the reaction temperature to 60 o C, then add 0.0375mol 1,4-butenediol, a drop of dibutyl-tin dilaurate, 50ml DMAC, then heat up to 85 o C continues to react.

[0044] (3) After the reaction in step (2) is carried out for 1 hour, carry out the titration of the -NCO group, and titrate once every 20 minutes until the theoretical value of the reaction of the -NCO group is reached, and then add 0.025mol of PTMEG-1000, Continue to react for 3 hours until the end of the reaction.

[0045] (4) Use a rotary evaporator to remove DMAC from the product obtained in step (3) to obtain a polyurethane material with carbon-carbon double bonds;

[0046] (5) Repeat the above steps or enlarge the experimental scale to...

Embodiment 2

[0048] Embodiment 2: UPy grafted polyurethane (PU-UPy)

[0049] figure 2 It is a synthetic circuit diagram for preparing PU-UPy in the present invention, steps (1)-(3) are the same as in Example 1, and other steps are as follows:

[0050] (4) Add 0.0125mol of UPy and 300ml of DMAC to the reactant in step (3), then raise the temperature to 85 o C was stirred and refluxed for 12 hours, the reaction was completed, and the DMAC in the reaction product was removed using a rotary evaporator to obtain PU-UPy.

[0051] (5) Repeat the above steps or enlarge the experimental scale to prepare PU-UPy in large quantities. After casting the prepared PU-UPy into the mold, place it at 60 o C blast oven to remove the remaining solvent to obtain polyurethane sheet samples.

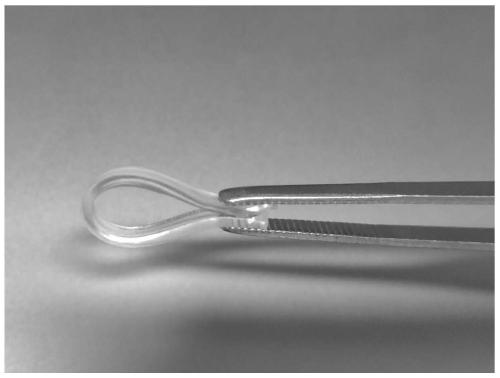

[0052] image 3 It is the state of the PU-UPy synthesized in this example in the polytetrafluoroethylene mold. Due to the introduction of carbon-carbon double bonds and UPy groups at the same time, it can be seen that ...

Embodiment 3

[0055] Embodiment 3: preparation epoxidized natural rubber

[0056] Weigh 100 parts of epoxidized natural rubber substrates with epoxidation degree of 25%, masticate for 5 minutes with a double-roller mill at room temperature, then add 1 part of vulcanizing agent dicumyl peroxide and 1 part of anti-aging agent in order. 1 part and 1 part of ultraviolet absorber, mixed and discharged evenly, and then placed in a flat vulcanizer, the vulcanization condition is: 135 o C, pressure 15MPa and molding time 5 minutes, obtain the epoxidized natural rubber sheet sample that does not mix polyurethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com