Oil-resistant rubber material without free-state sulfur

A technology of oil-resistant rubber and rubber materials, which is applied in the field of rubber materials and can solve the problems of serious injuries to workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

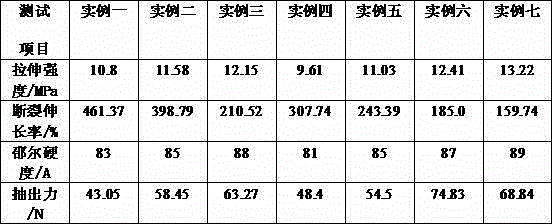

Examples

example 1

[0022] Example 1: Put 80g of nitrile rubber (N41) and 20g of rubber-plastic alloy (N7030) into the double-roll mill for masticating, then add 5g of activator zinc oxide, 1g of stearic acid, and anti-aging agents 2, 2, 4 in sequence - Trimethyl-1,2-dihydroquinoline polymer (RD) 1.5g and N-isopropyl-N, phenyl-p-phenylenediamine (4010NA) 1.5g, white carbon black 15g, calcium carbonate 40g, Reinforcing carbon black N330, N550, and N774 are 35g, 35g, and 40g respectively, plasticizer dioctyl sebacate (DOS) 25g, binder AS-885g, and finally add a vulcanizing agent: dipentamethylene tetrasulfide Thiuram (TRA) 3g, accelerator dibenzothiazole disulfide (DM) 1.5g, uniformly mixed on an open mill to obtain a compound rubber, and then vulcanized on a plate at 150°C to obtain a vulcanized rubber, and then the vulcanized rubber was punched After testing its mechanical properties and oil resistance, see Table 1 and Table 4.

example 2

[0023] Example 2: The composition of this example is basically the same as that of Example 1, except that 70g of nitrile rubber (N41) is used instead of 80g of nitrile rubber (N41), and 30g of rubber-plastic alloy (N7030) is used instead of 20g of rubber-plastic alloy (N7030). , the experimental method is consistent with Example 1.

example 3

[0024] Example 3: The composition of this example is basically the same as that of Example 1, except that 60g of nitrile rubber (N41) is used instead of 80g of nitrile rubber (N41), and 40g of rubber-plastic alloy (N7030) is used instead of 20g of rubber-plastic alloy (N7030). , the experimental method is consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com