Preparation method of high-purity collagen protein sponge

A collagen sponge and collagen technology, applied in the direction of animal/human protein, connective tissue peptide, specific peptide, etc., can solve the problems of long production cycle of collagen sponge, poor hemostatic performance, low yield, etc., and shorten the production cycle , short time, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

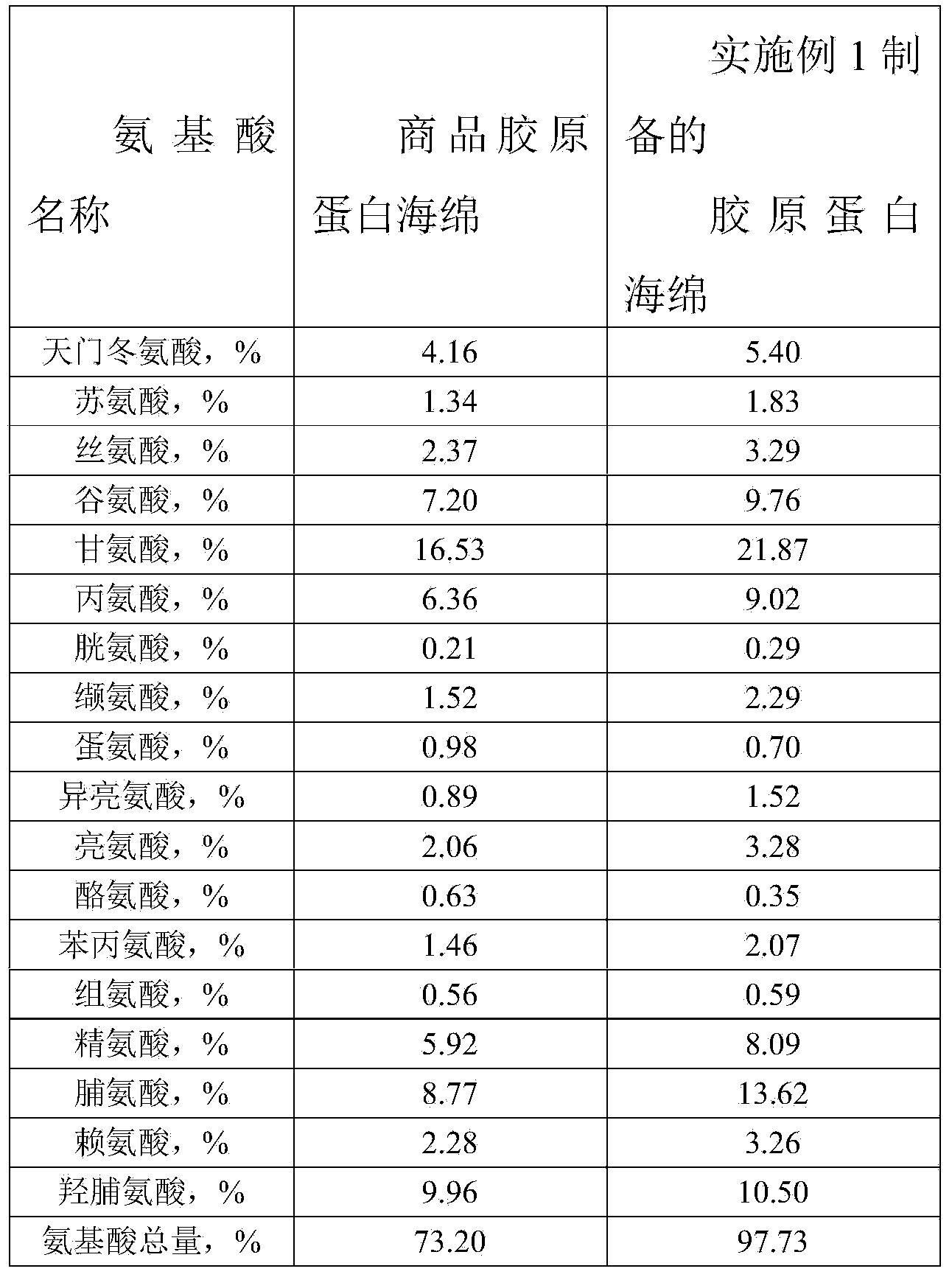

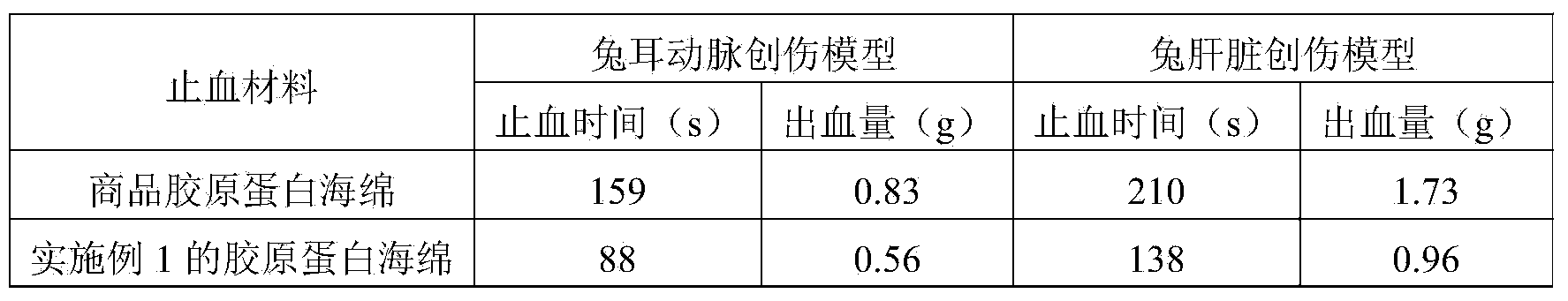

specific Embodiment approach 1

[0030] Specific embodiment one: the preparation method of the high-purity collagen sponge of the present embodiment is carried out according to the following steps:

[0031] 1. Pretreatment of fresh beef Achilles tendon: remove fascia and grease from 100-250g fresh beef Achilles tendon, wash and cut into small pieces of 0.5cm×0.5cm, put them into a tissue masher, add 300-500ml Distilled water, turn on the machine and mash, then wash with distilled water, then soak in 1000ml of sodium carbonate solution with a mass concentration of 0.05% to 3% for 10 to 24 hours, filter, and dry the precipitate in a natural state;

[0032] 2. Extraction of collagen: put 5-50g of dried bovine Achilles tendon into a three-necked flask, add 500-1500ml of acetic acid with a mass concentration of 0.1%-5%, stir to dissolve it, and then add 100-500ml containing 0.5 ~5g of pepsin or ficin with 0.1%~5% acetic acid in mass concentration, and then placed in a constant temperature water tank at 5°C, stirre...

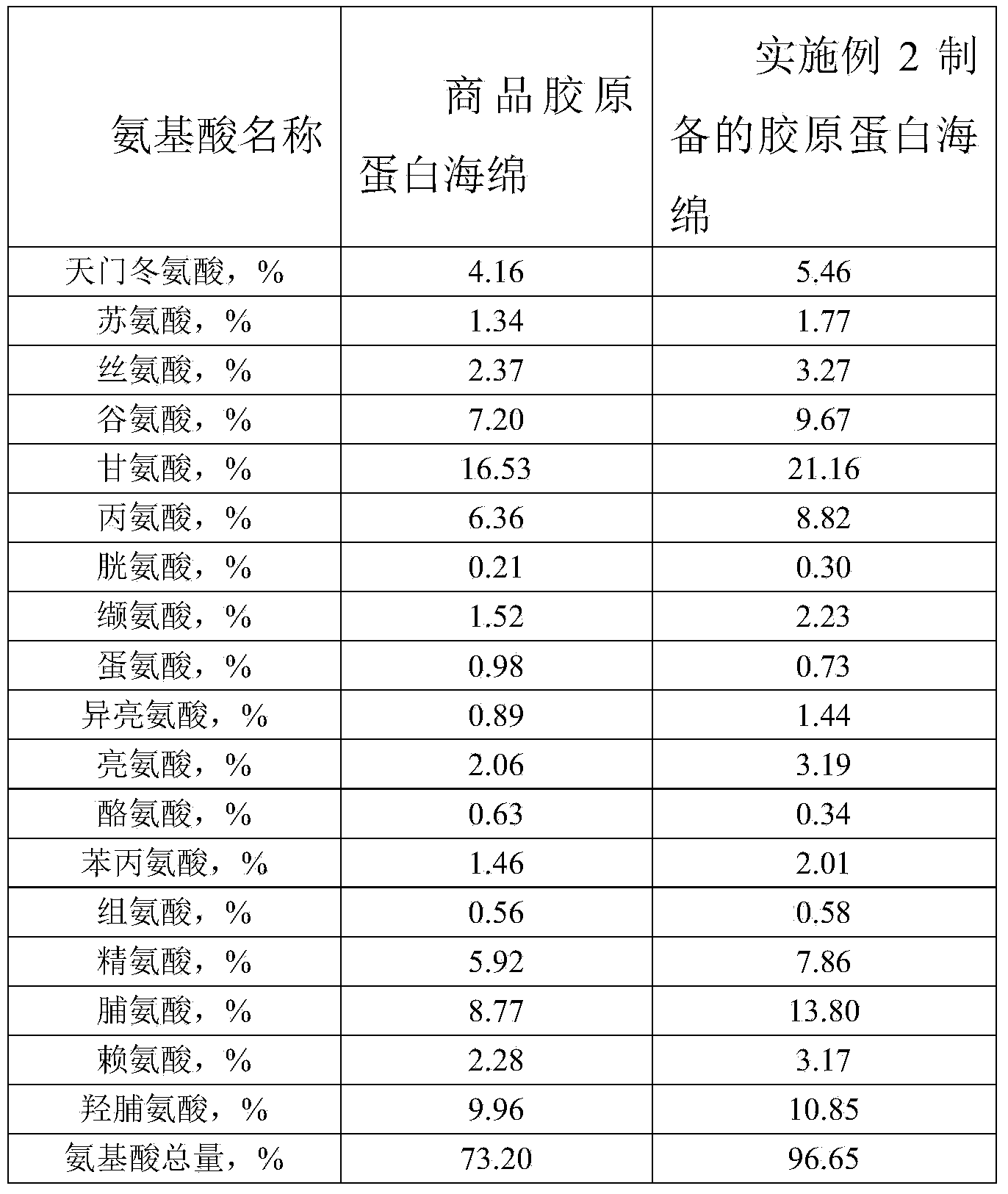

specific Embodiment approach 2

[0045] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, use 1000ml mass concentration of 0.8% sodium carbonate solution to soak for 12h. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0046] Specific embodiment three: what this embodiment is different from specific embodiment one or two is that in step 2, the bovine Achilles tendon after 25g drying is placed in the there-necked flask, adding 800ml mass concentration is the acetic acid of 1.2%, stirring makes it dissolve, Then add 500ml of acetic acid with a mass concentration of 1.2% containing 3.5g of pepsin or ficin, and then place it in a constant temperature water tank at 5°C with even intermittent stirring and extract for 3.5 days. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com