Method for preparing sol of neutral Nano titanium dioxide

A nano-titanium dioxide, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of corrosion and damage of substrates, increase environmental protection costs, limit the scope of application, etc., and achieve strong adhesion, easy operation, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1. prepare titania sol with tetrabutyl orthotitanate as raw material

[0034] Tetrabutyl orthotitanate is used as raw material, ethanol is used as solvent, and acetic acid is used as catalyst. Add 80ml of absolute ethanol dropwise to 20ml of tetrabutyl orthotitanate under vigorous stirring to prepare solution A, uniformly mix 10ml of water, 84ml of ethanol and 15ml of acetic acid to prepare solution B; Drop into B. After the dropwise addition, stop stirring to obtain light yellow transparent TiO 2 Sol. The sol was aged under natural conditions to form a gel, which was dried at 55°C to obtain an amorphous titanium dioxide solid. Add water to the amorphous titanium dioxide to make a suspension, stir constantly, slowly add hydrogen peroxide, wherein the ratio of hydrogen peroxide to titanium dioxide is 1.5, and then place it in an ultrasonic machine for ultrasonic treatment for 1 hour until dissolved to obtain a yellow solution. Transfer the yellow solution ...

Embodiment 2

[0035] Embodiment 2. With Ti(OBu) 4 Preparation of titania sol as raw material

[0036] Take Ti(OBu) 4 As a raw material, ethanol is used as a solvent and acetic acid is used as a catalyst. Add 80ml of absolute ethanol dropwise to 17ml of Ti(OBu) under vigorous stirring 4 Solution A was prepared in , and solution B was prepared by uniformly mixing 10ml of water, 84ml of ethanol and 15ml of acetic acid; then A was dropped into B under vigorous stirring. After the dropwise addition, stop stirring to obtain light yellow transparent TiO 2 Sol. The sol was accelerated to gel formation under microwave conditions, and it was dried at 50°C to obtain amorphous titanium dioxide solid. Add water to the amorphous titanium dioxide to make a suspension, stir constantly, slowly add hydrogen peroxide, wherein the ratio of hydrogen peroxide to titanium dioxide is 1.0, and then place it in an ultrasonic device for ultrasonic treatment for 1.5 hours until dissolved to obtain a yellow soluti...

Embodiment 3

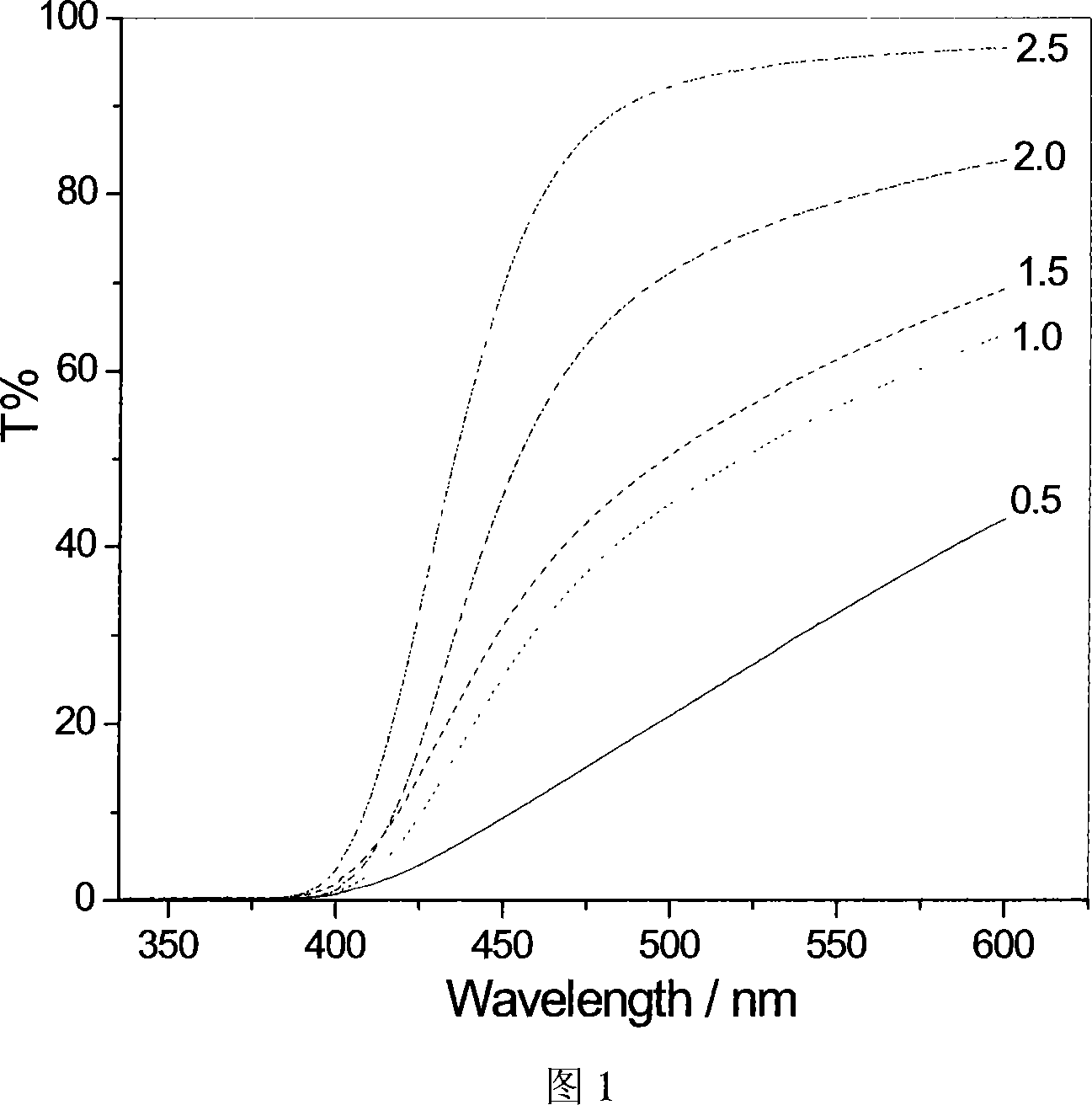

[0037] Embodiment 3. Taking titanyl sulfate as raw material in different H 2 o 2 / TiO 2 Compared to the light transmittance of prepared titanium dioxide sol

[0038]Weigh 90g of titanyl sulfate solid (purity is 93%), add water to beat and mix, stir until transparent; add excess sodium hydroxide solution dropwise to adjust the pH to above 10, stir for 2 hours, then repeatedly filter and wash until there is no sulfate ion (Titration detection with 0.5M barium chloride solution), and then repeatedly washed with distilled water until neutral, so that the impurity ions can be basically removed. Add water to the amorphous titanium dioxide precipitate to make a suspension, keep stirring, and slowly add hydrogen peroxide, wherein the ratio of hydrogen peroxide to titanium dioxide is 0.5, 1.0, 1.5, 2.0 and 2.5 respectively, and then place them in an ultrasonic machine for ultrasonic treatment for 1 hours until dissolved to give a yellow solution. The yellow solution was transferred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com