Patents

Literature

65results about How to "No trace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superstrong-muting PE (polyethylene) core layer micro-foamed drainage pipe and manufacturing method thereof

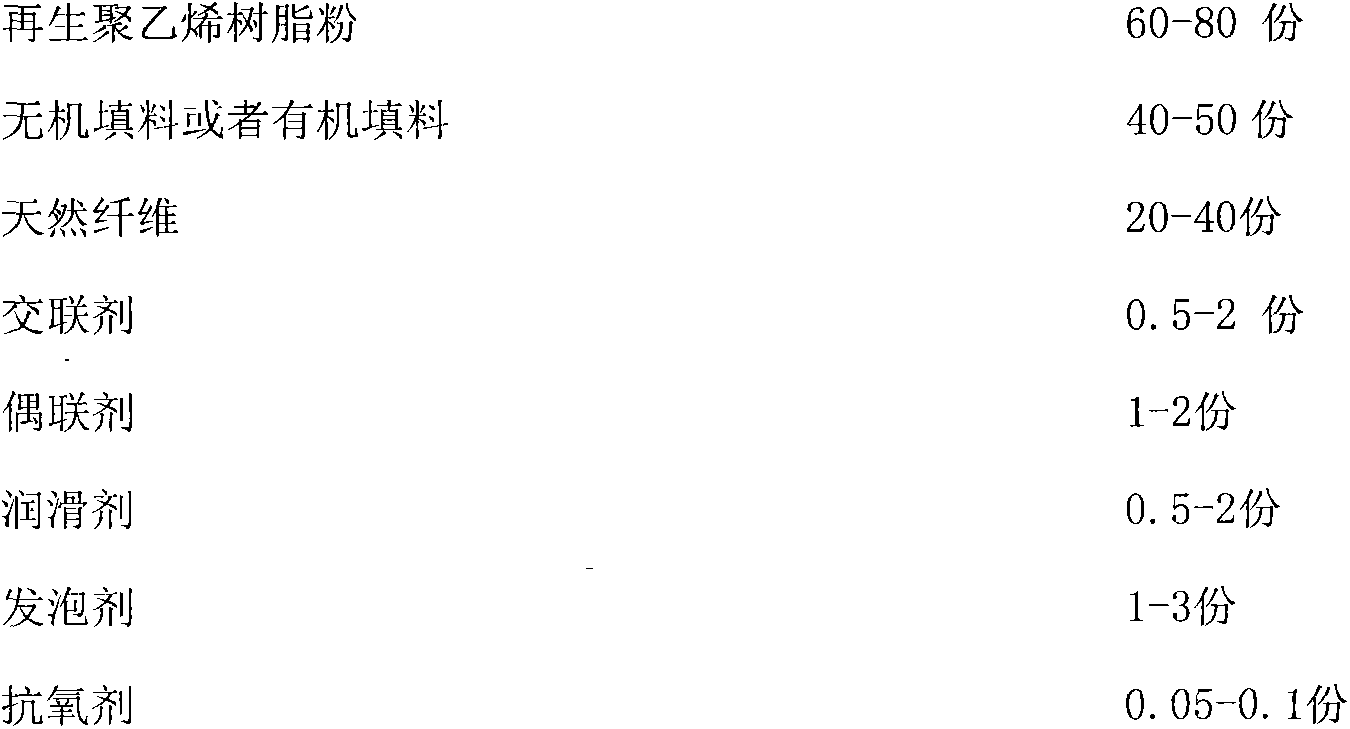

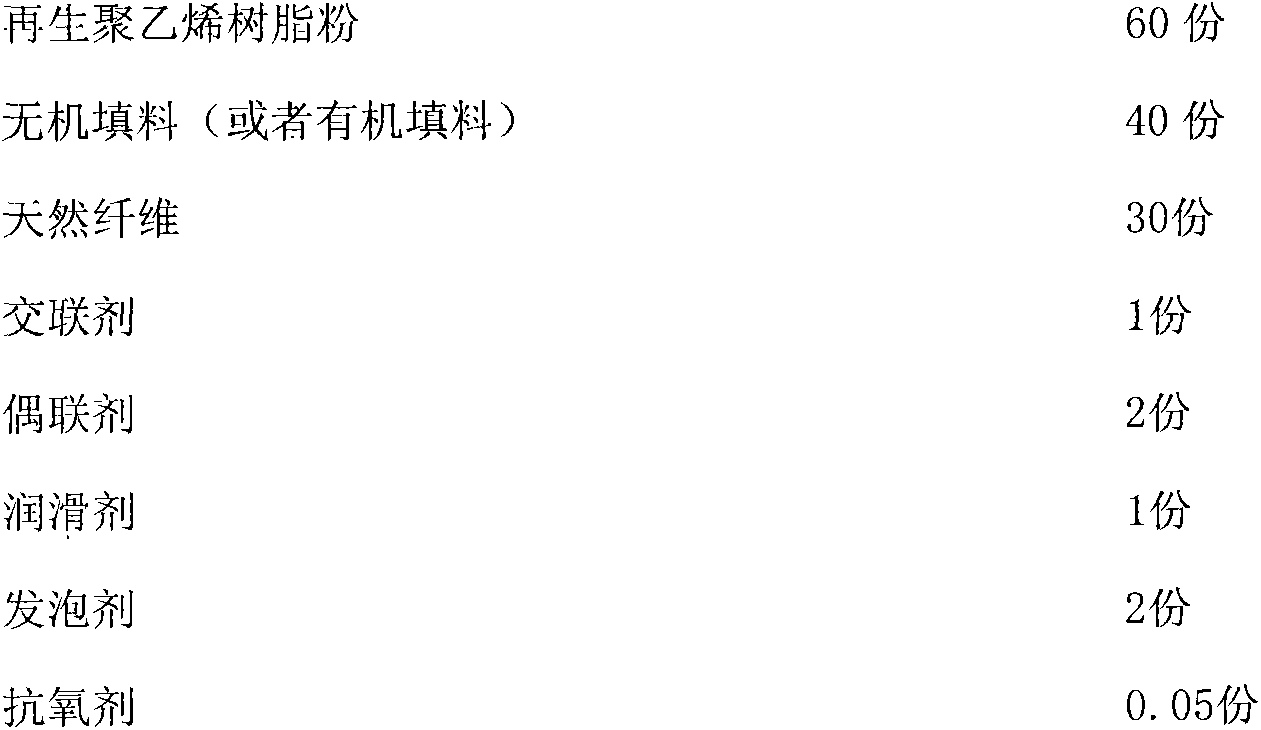

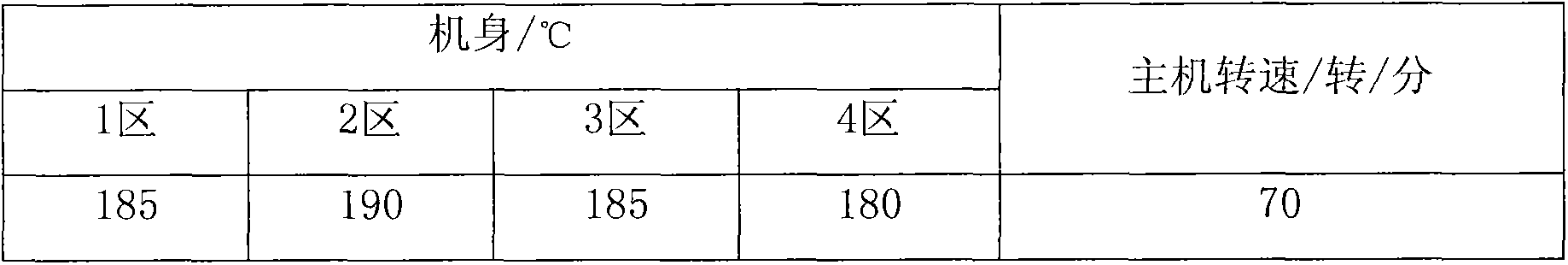

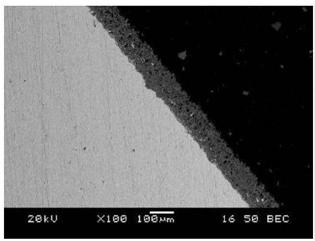

The invention belongs to the field of pipes, relates to an enhanced drainage pipe and mainly relates to a superstrong-muting PE (polyethylene) core layer micro-foamed drainage pipe which is suitable for wastewater discharging, engineering transforming projects and home decoration of villa communities, high-rise residential communities, high-grade residential apartment communities and the like and industrial building fields like water discharging, sewage discharging, waste discharging and the like of industrial enterprises. The superstrong-muting PE composite drainage pipe is a multilayer composite body formed by a high-density polyethylene resin inner layer, a middle PE micro-foamed layer and a high-density polyethylene resin outer layer, the thickness ratio of the inner layer, the middle layer and the outer layer is 1:4:1, and the PE micro-foamed layer is composed of regenerated polyethylene resin powder, inorganic filler or organic filler, natural fibers, a cross-linking agent, a coupling agent, a lubricating agent, a foaming agent and an antioxidant. The superstrong-muting PE core layer micro-foamed drainage pipe has excellent denoising and muting performance, superstrong resistance to chemical corrosion and good impact resistance.

Owner:LINYI DONGLI PLASTIC BUILDING MATERIAL CO LTD

Manufacturing process of solid wood composite door

ActiveCN104742210AReduce crackingReduces shedding defectsWood working apparatusSolid woodStanding frame

The invention discloses a manufacturing process of a solid wood composite door. The manufacturing process of the solid wood composite door comprises the following steps that 1, a door leaf, a door casing, a plate A and a plate B are prepared at the same time, the prepared door leaf, door casing, plate A and plate B are spliced after paint spraying, and in the mounting process, the two sides of a stand frame of the spliced door leaf are spliced with a side door sleeve plate B through silica gel strips, the side door sleeve plate B and a side door sleeve plate A are spliced, a side casing wire is arranged on one side of the side door sleeve plate B, and a side door casing wire is arranged on one side of the side door sleeve plate A; in the mounting process, the side casing wire and the side door casing wire are fixed to a wall to complete mounting of a wooden door. The manufacturing process is simple and easy and convenient to operate, labor productivity is improved, production time is saved, production cost is lowered, and greater benefits are obtained.

Owner:JIANGSU KENTIER SENGONG TECH

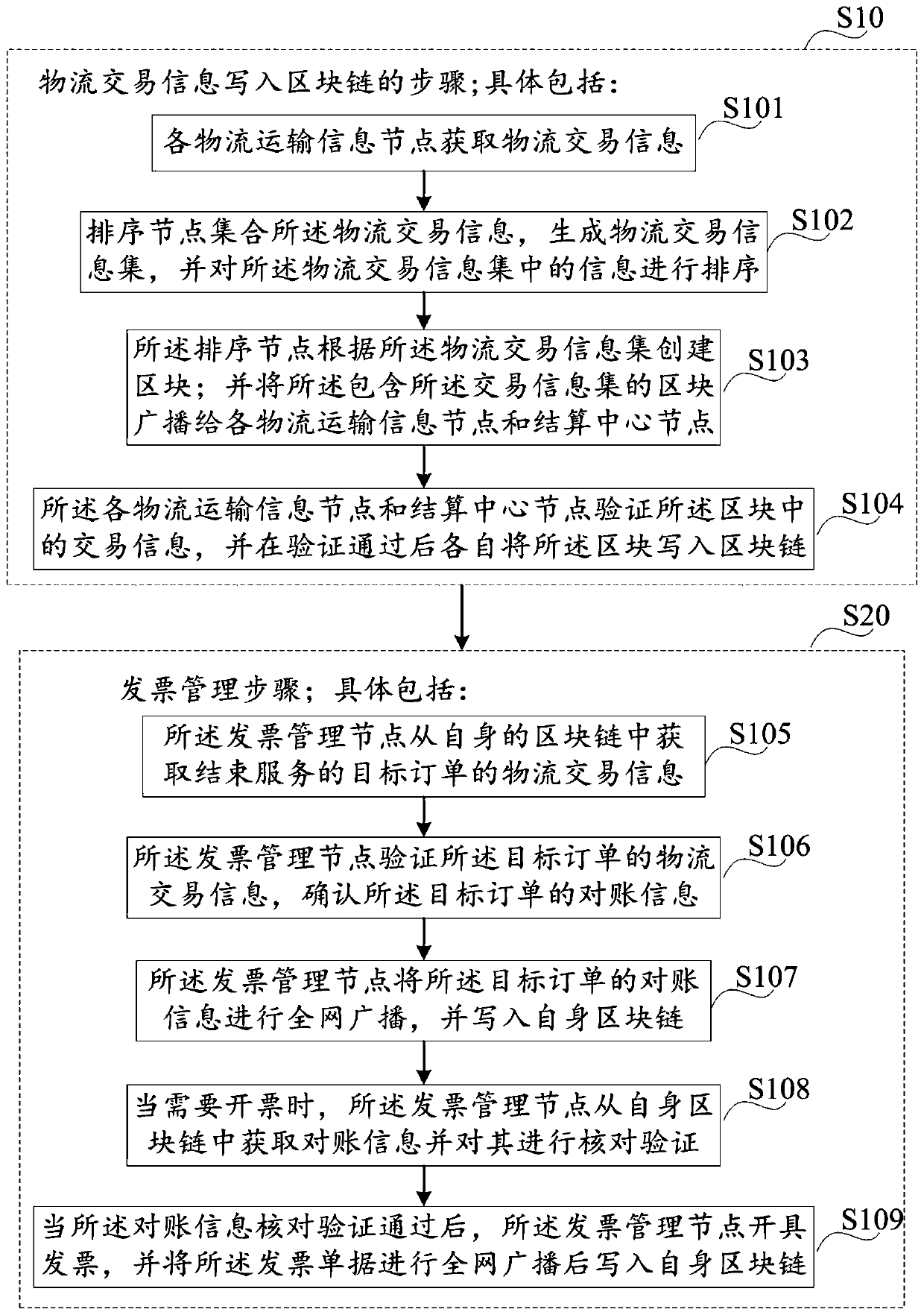

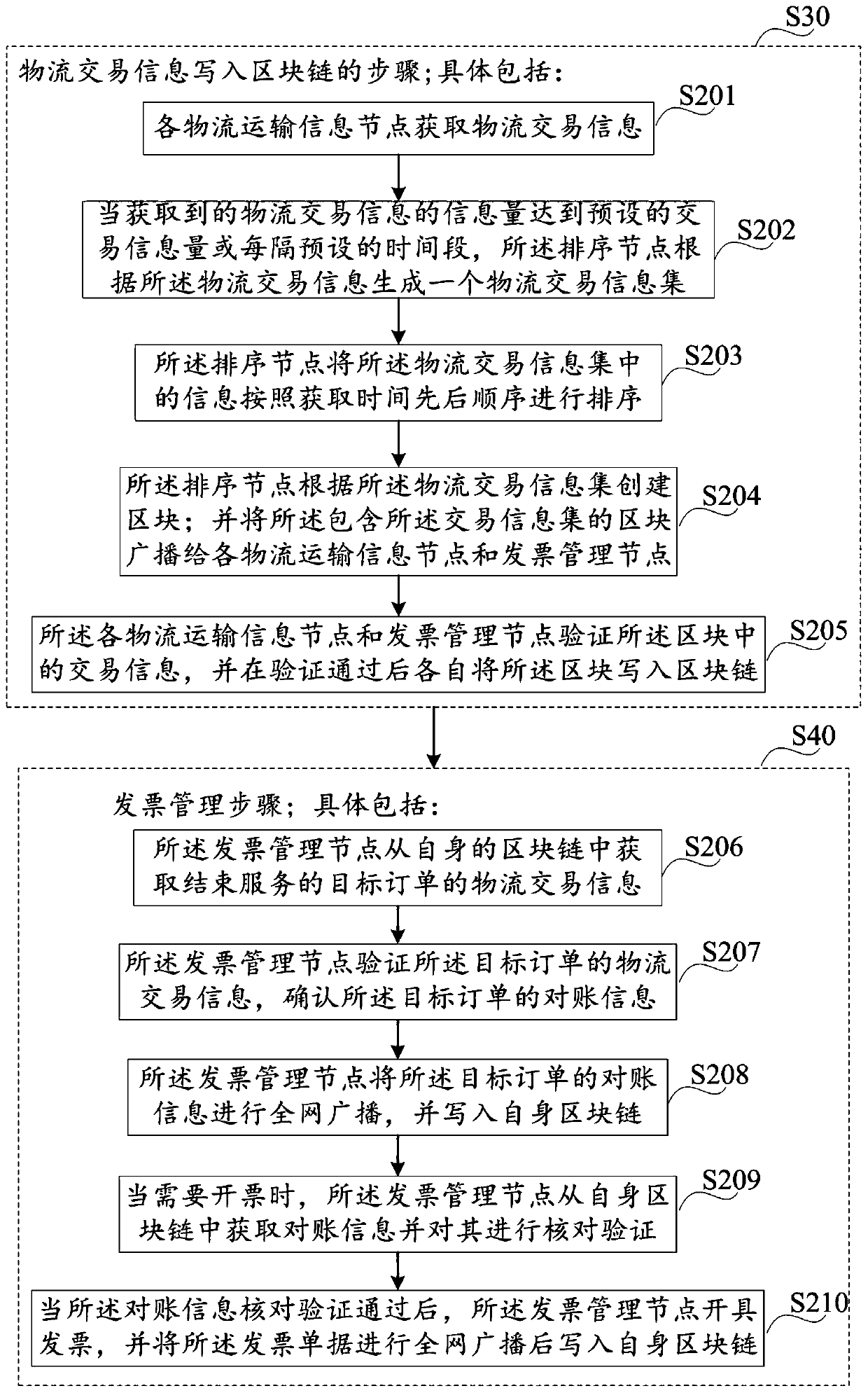

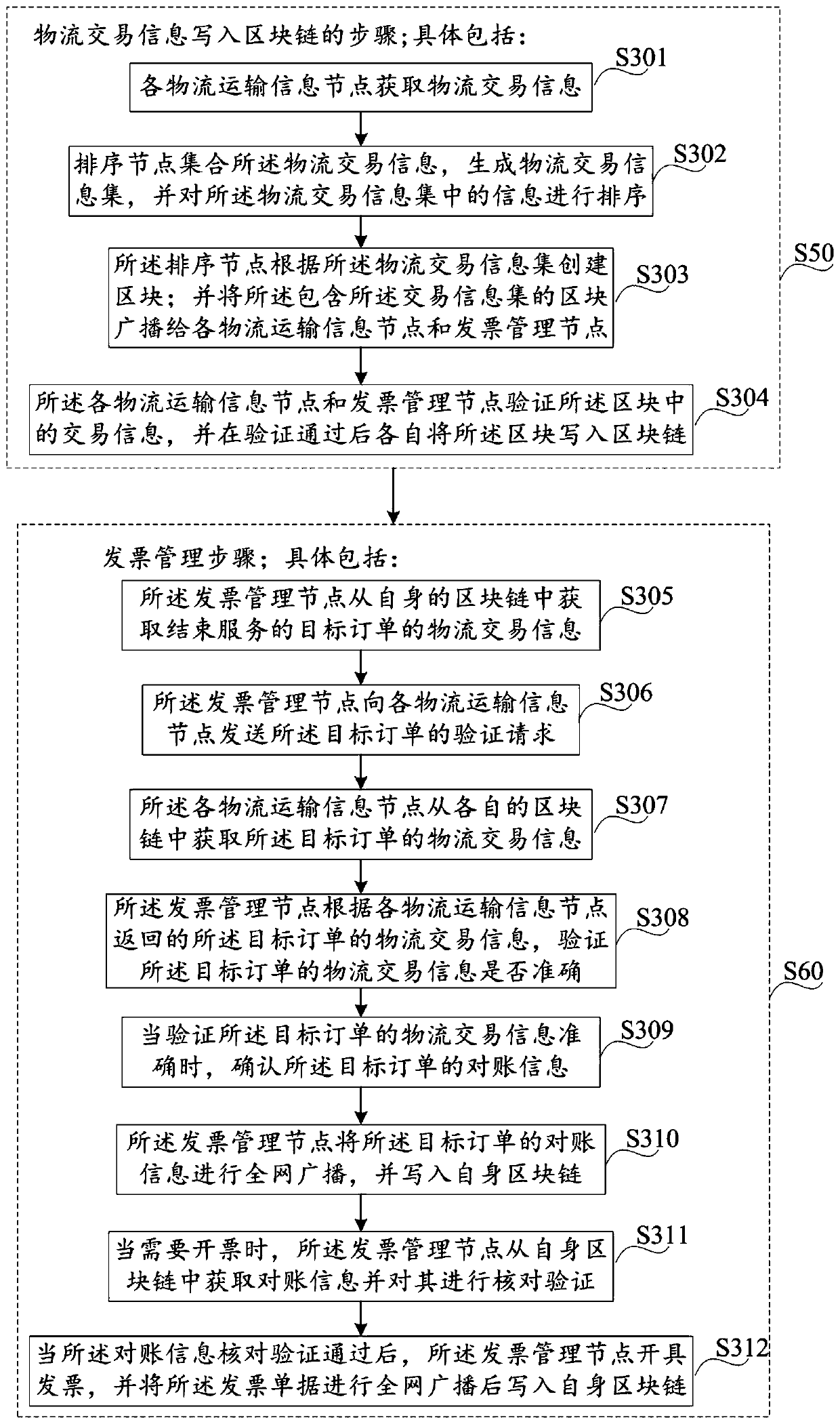

Invoice management method and system based on block chain

PendingCN110472914APrevent tamperingRealize credible dataFinanceDigital data protectionBlockchainInvoice

Owner:上海天地汇供应链科技有限公司

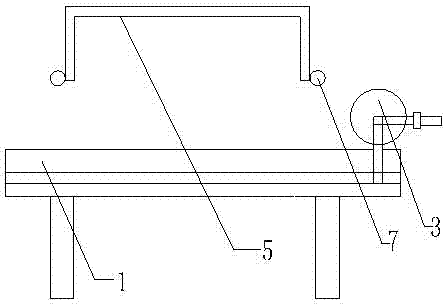

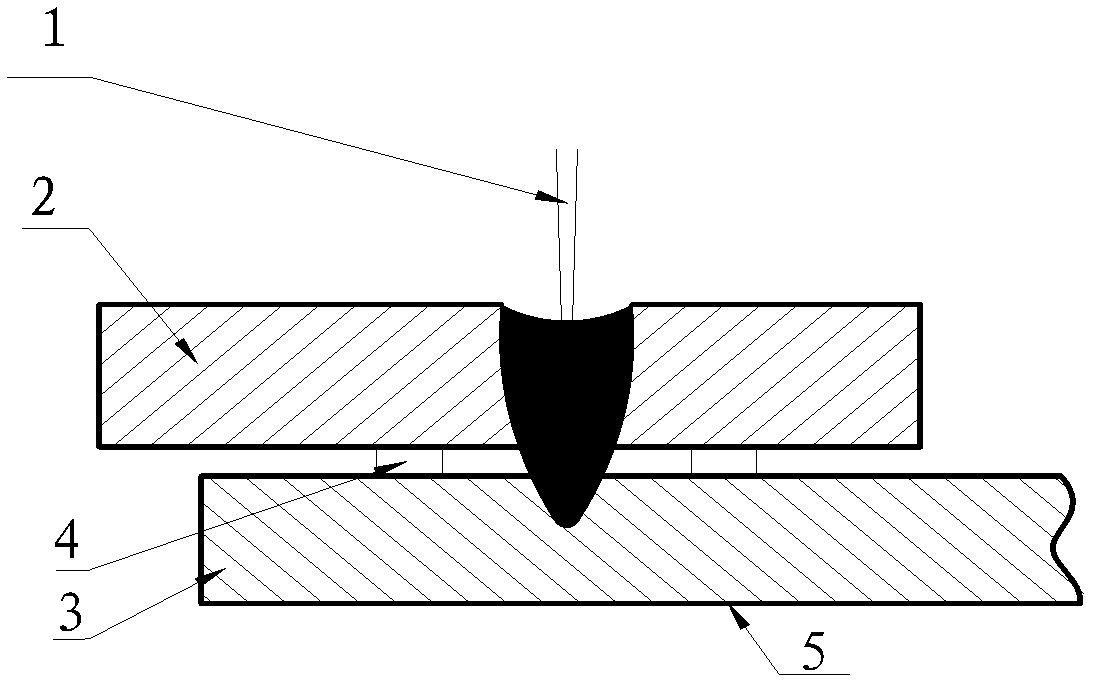

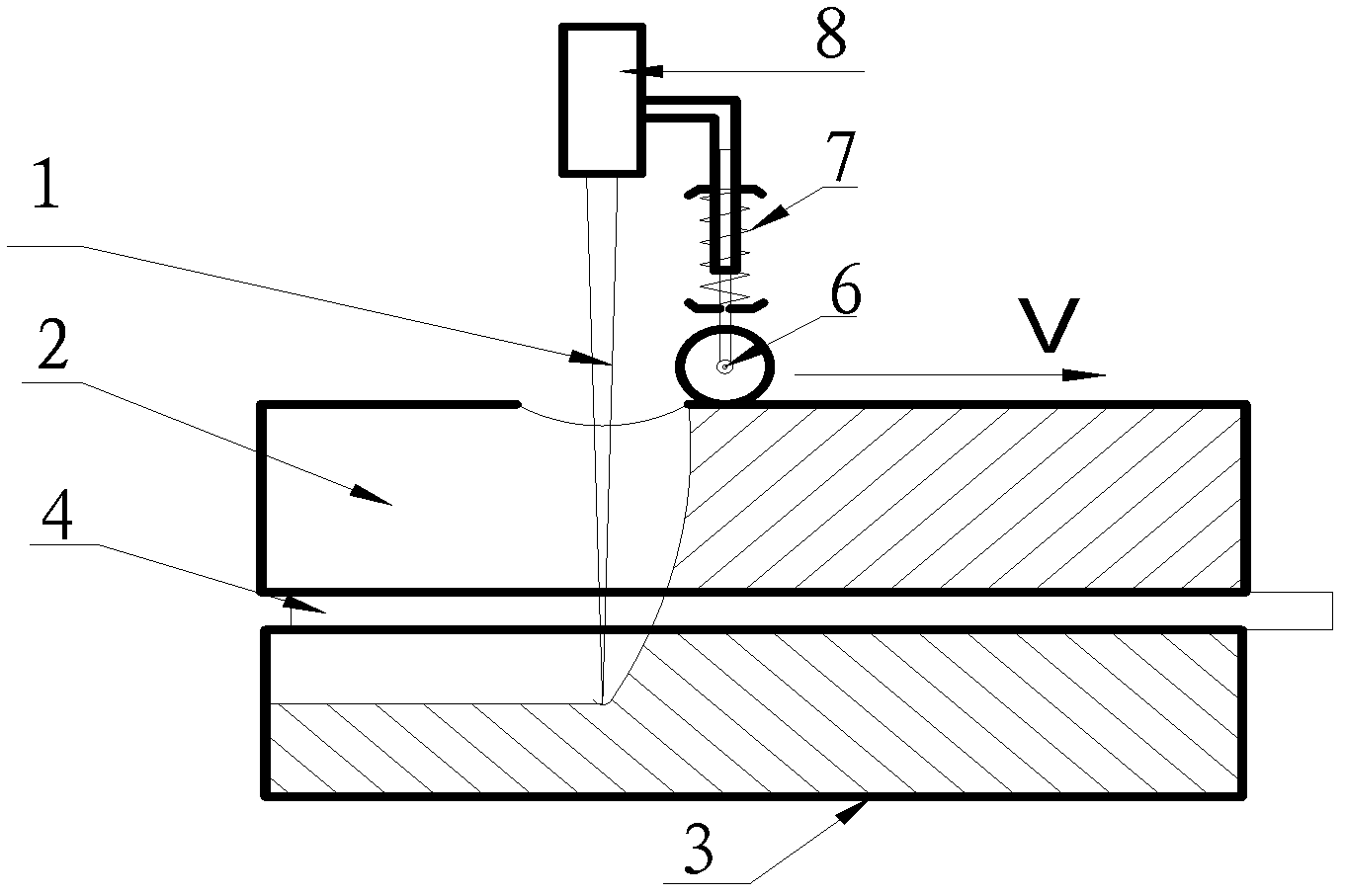

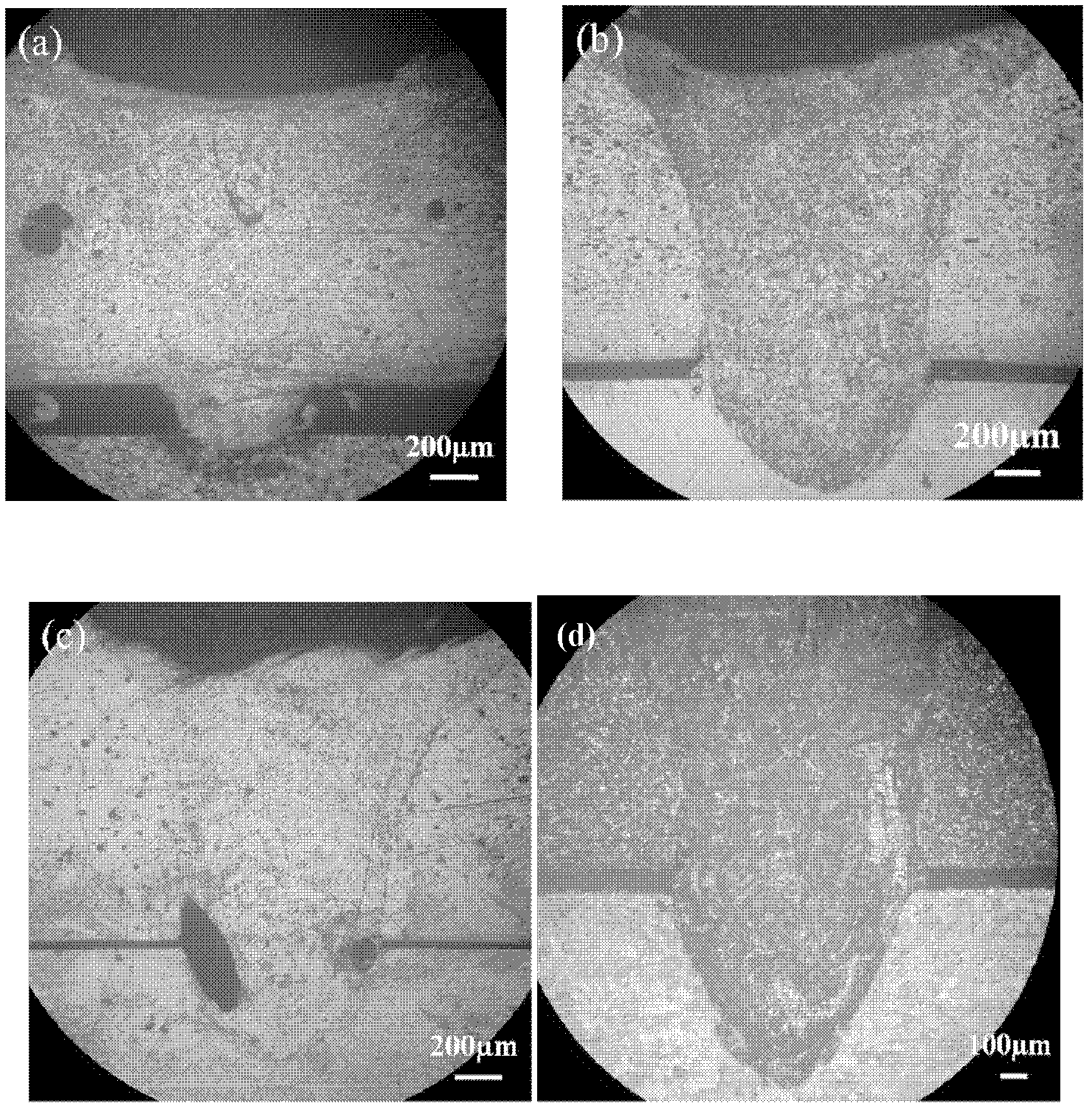

Single-surface traceless welding method for stainless steel composite panel of elevator

ActiveCN102248297AHigh strengthGuarantee the appearance qualityLaser beam welding apparatusSheet steelShielding gas

The invention discloses a single-surface traceless welding method for a stainless steel composite panel of an elevator, comprising the following steps of: (1) eliminating oil stains on respective surfaces to be welded of a cold (hot) rolled steel plate and a stainless steel surface plate; (2) placing the stainless steel surface plate on a work table, respectively placing a separation bar at two sides of a position to be welded and 5-10 mm away from the position to be welded, and then placing the cold (hot) rolled steel plate on the separation bar so that a gap of 0.08-0.12mm is reserved between the cold (hot) rolled steel plate and the stainless steel surface plate; (3) carrying out laser welding on the cold (hot) rolled steel plate and the stainless steel surface plate with a mixed gas of oxygen gas and inert gas as a protective gas to ensure that a welding seam penetrates through the cold (hot) rolled steel plate and the depth of the welding seam on the stainless steel surface plate is controlled to be 1 / 3-1 / 2 of the thickness of the stainless steel surface plate; and ensuring that the stainless steel surface plate, the cold (hot) rolled steel plate and the separation bar are clamped tightly in a welding process. The method provided by the invention has the characteristics of no trace on a single stainless steel panel surface, high welding seam quality and high strength of a combination structure.

Owner:ZHEJIANG UNIV OF TECH +1

Cleaning solution and preparation method thereof

ActiveCN103773612ABiodegradableMild performanceOrganic detergent compounding agentsSurface-active detergent compositionsSilicone fluidSodium benzenesulphonate

The invention discloses a cleaning solution and a preparation method thereof. The cleaning solution comprises the following components in parts by weight: 2-8 parts of sodium alkyl benzene sulfonate, 1-5 parts of sodium silicate, 0.5-1 part of nipagin, 0.5-1 part of dimethicone, 0.5-2 parts of cyclohexane, 20-30 parts of alcohol, 60-70 parts of isopropanol and 30-40 parts of deionized water. The preparation method comprises the steps: heating the deionized water to 70-80 DEG C, then adding sodium alkyl benzene sulfonate, nipagin, sodium silicate, and dimethicone, uniformly stirring, cooling and homogenizing, adding cyclohexane, alcohol and isopropanol after cooling to room temperature, and uniformly stirring to obtain the cleaning solution. The cleaning solution provided by the invention is environment-friendly and pollution-free, is capable of well preventing corrosion and bacteria, and is mild in performance and suitable for popularization and use.

Owner:NANTONG SUTONG SEPARATION ENG & TECH

Full hemp liner for men's suits and manufacturing method thereof

InactiveCN101637319AStructural fitStrong three-dimensional senseGarmentsClothes making applicancesEngineeringFormaldehyde

The invention discloses a full hemp liner for men's suits, which comprises a bodice liner, a front chest liner, an armhole liner, an internal shoulder liner, an external shoulder liner and a bias chest liner. The invention also discloses a manufacturing method of the full hemp liner for men's suits, which comprises the following steps: putting the full hemp liner in a container, leading steam intothe container, and steaming the full hemp liner at the high temperature of 110-120 DEG C for 12-16 hours; then, taking out the full hemp liner, and cooling and airing the full hemp liner; and shrinking, expanding, shaping, pressing and ironing the full hemp liner to obtain a finished product. The full hemp liner for men's suits has the advantages of natural and neat wear and good air permeability, better joints the structure of a human body, does not contain formaldehyde and does not need a bonding liner. In addition, because the high-temperature steaming technology is adopted in the manufacturing process, the raw liner is made into a steamed liner, thus the liner is softer and can not be deformed by ironing.

Owner:NINGBO SHANSHAN +1

Washing liquid for solar cell silk screen printing process

InactiveCN101531955AAvoid damageEasy to cleanFinal product manufactureOrganic non-surface-active detergent compositionsScreen printingAlcohol

The invention discloses a washing liquid for a solar cell silk screen printing process, which consists of C3-C12 ether, C3-C9 ester, C2-C5 alcohol, C5-C18 alcohol ether compound and an additive. The invention provides a solvent type washing liquid, which is suitable for the solar cell industry, is particular suitable for washing metal slurry, resin, oil stains and printing equipment, has high washing efficiency and small pollution, toxicity and damage to human bodies, and is dry quickly without residual marks after washing.

Owner:HANWHA SOLARONE QIDONG +1

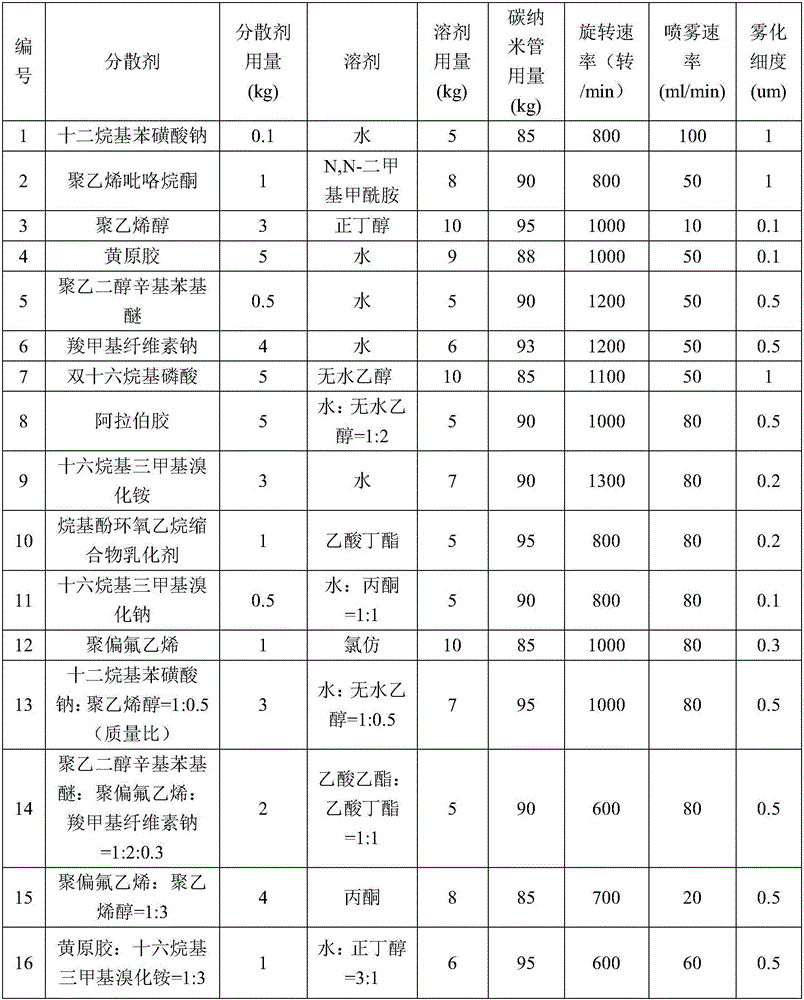

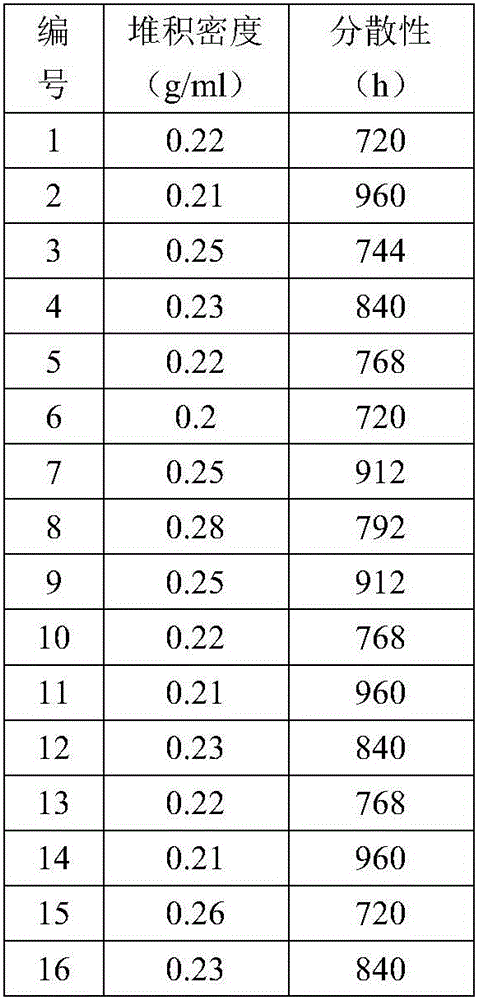

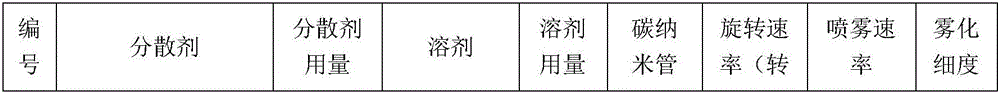

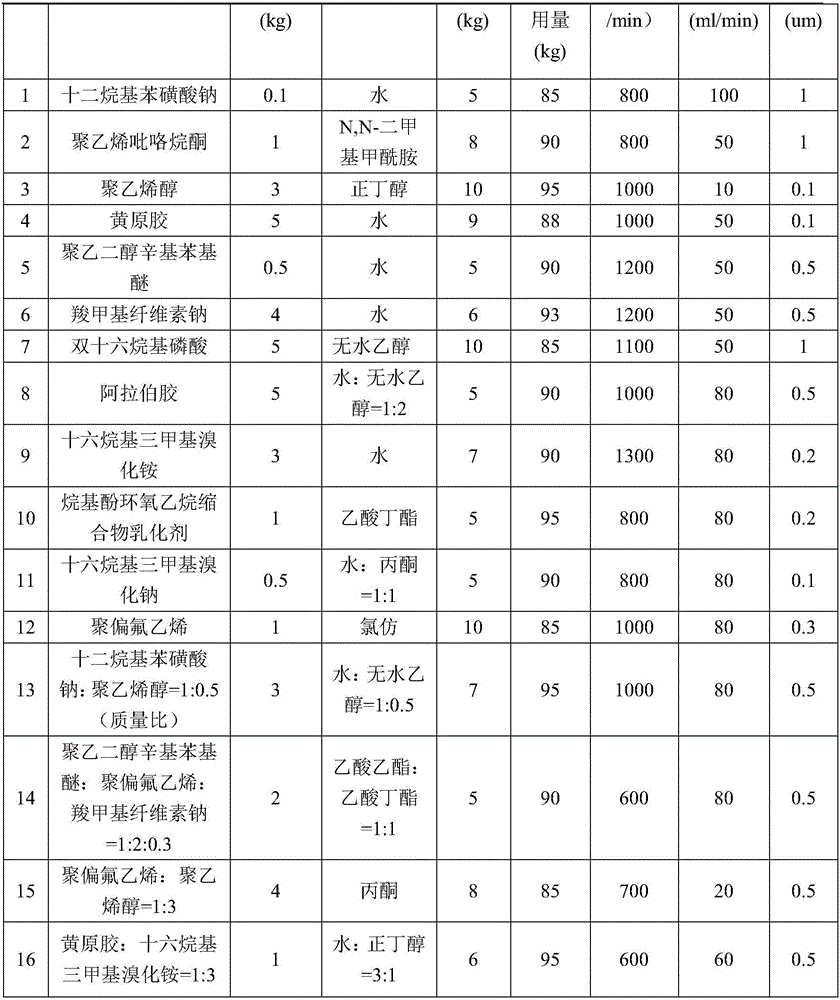

Carbon nanotube modified PET antistatic thin film

The invention discloses a carbon nanotube modified PET antistatic thin film. A method for preparing the carbon nanotube modified PET antistatic thin film includes: stirring carbon nanotube at a high speed; at the same time, dissolving a dispersant in a liquid, and spraying the liquid into carbon nanotube powder while being stirred to activate the surface of the carbon nanotube; adding obtained activated carbon nanotube as a conductive filling agent into a PET material matrix to prepare PET / carbon nanotube conductive masterbatch good in conductive performance; mixing the PET / carbon nanotube conductive masterbatch with auxiliaries like PET matrix resin, a thermal oxidation stabilizer, a flow modifier and a friction-resistant agent, and obtaining the PET antistatic thin film through blow molding, tape casting or bidirectional stretching processes. The PET antistatic thin film prepared by the method is good in conductive performance, high in antistatic durability and long in service life.

Owner:嘉兴高正新材料科技股份有限公司

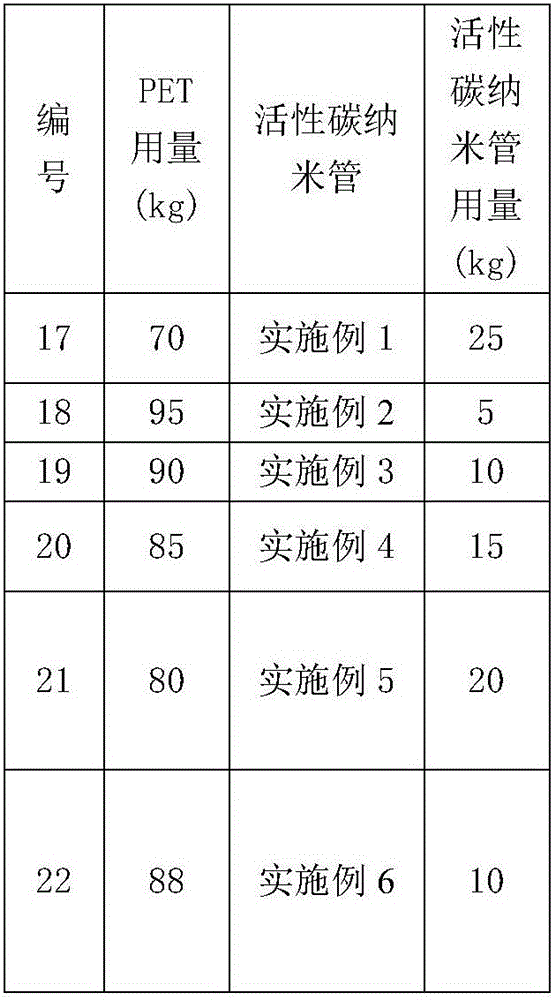

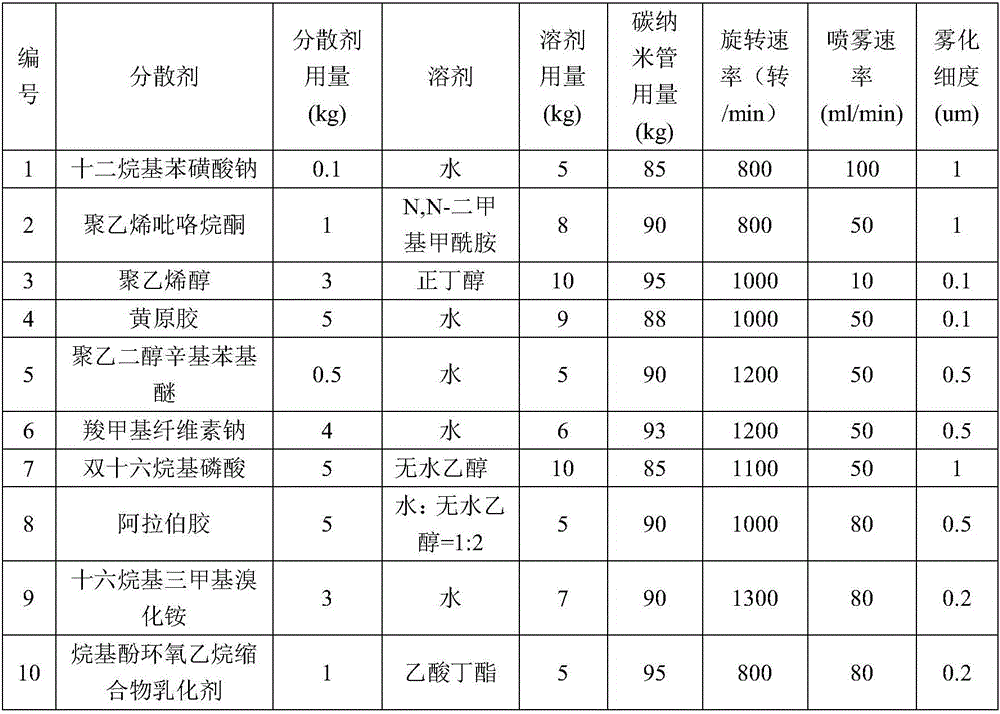

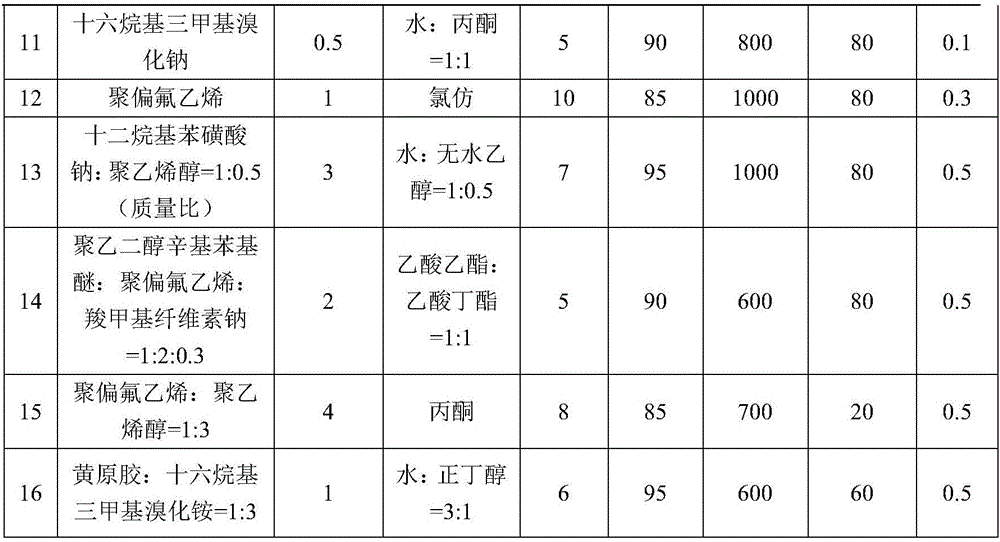

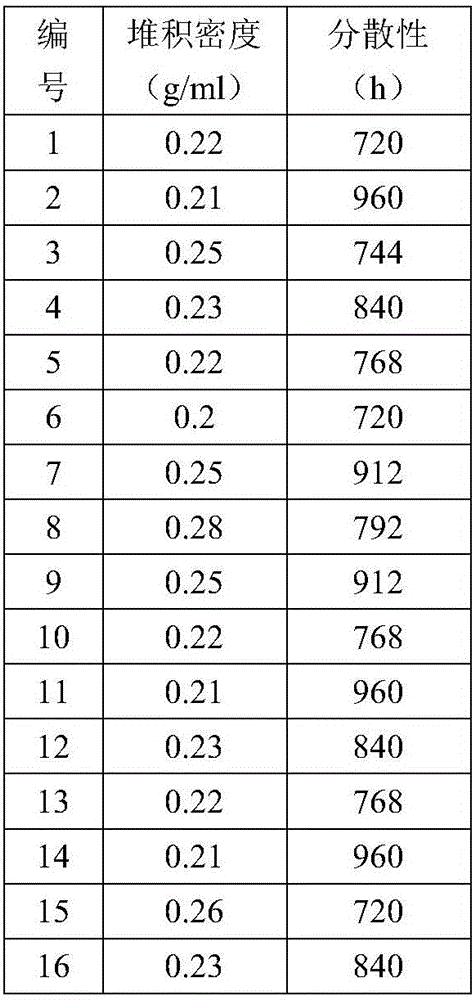

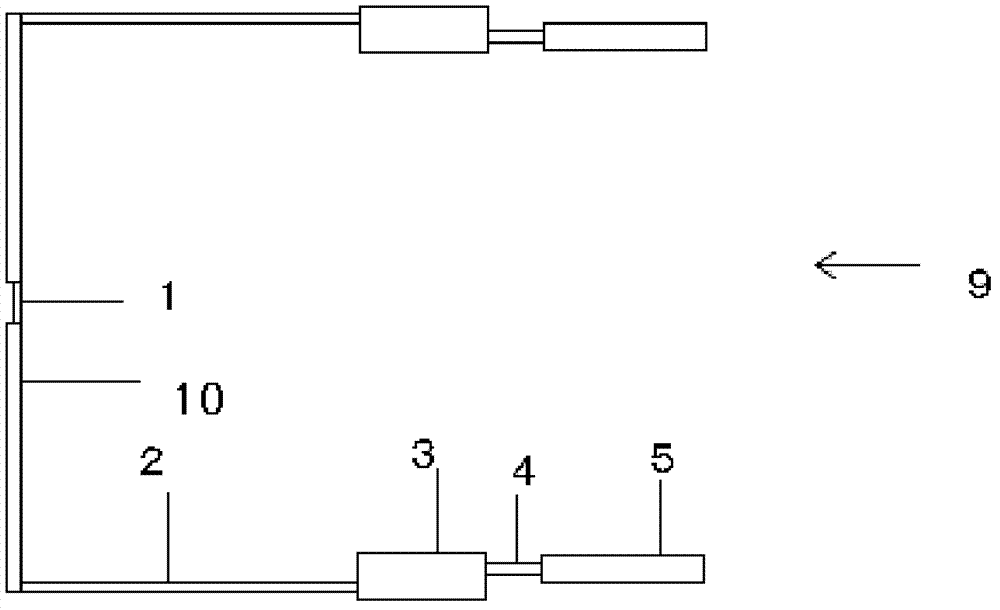

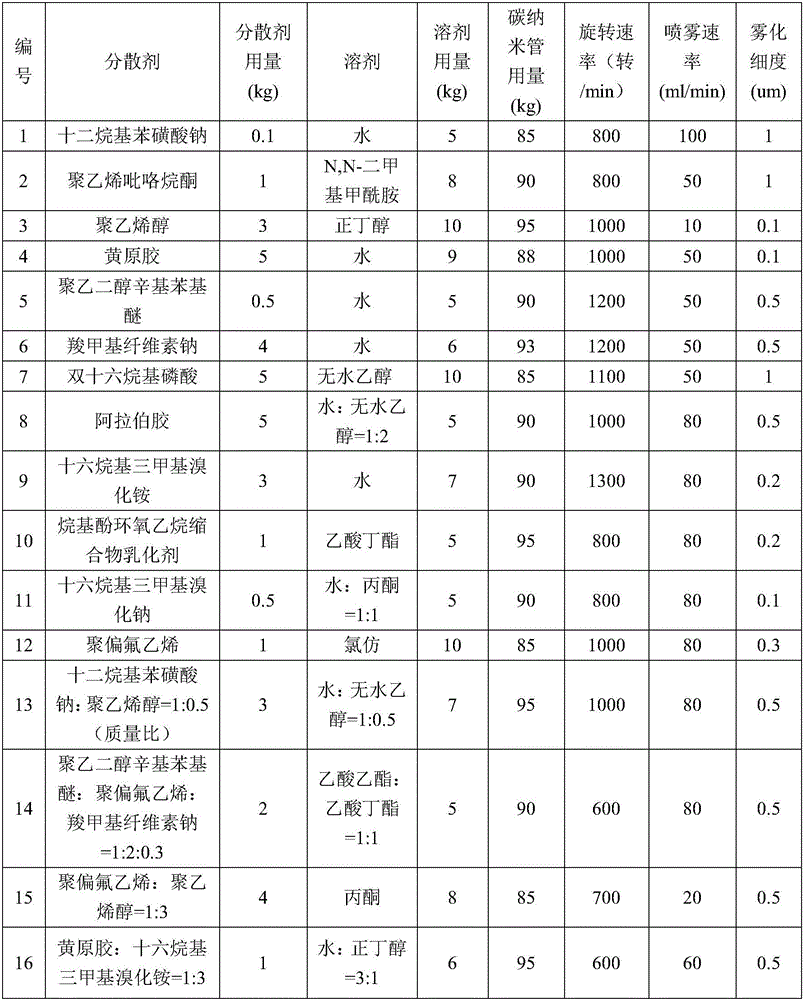

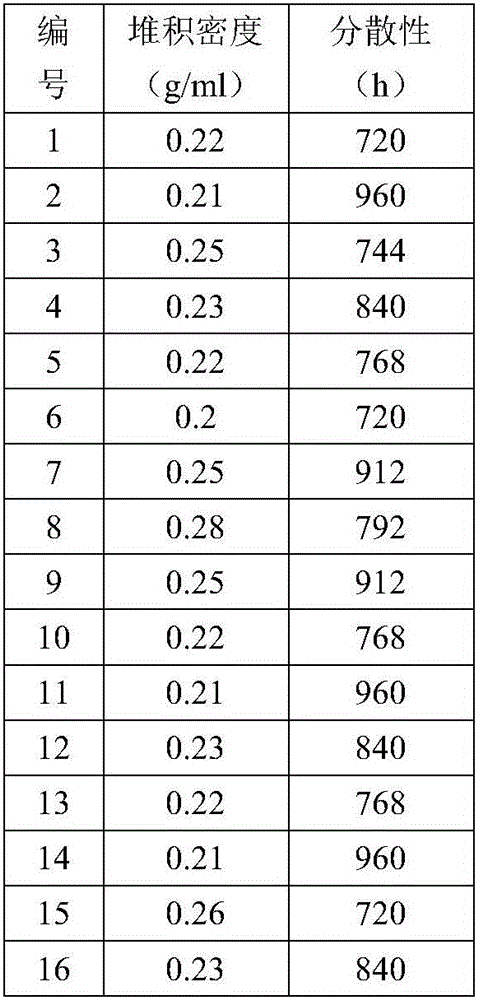

Active carbon nanotube modified polyethylene antistatic thin film

The invention discloses an active carbon nanotube modified polyethylene antistatic thin film. The active carbon nanotube modified polyethylene antistatic thin film is prepared from the following components in parts by mass: 70 to 95 parts of a PE (Polyethylene) polymer matrix material, 0.01 to 10 parts of active carbon nanotubes and 0.1 to 20 parts of an auxiliary agent; the auxiliary agent is formed by mixing one or more than two of a dispersant B, a coupling agent, an antioxidant, a lubricant and an anti-abrasion agent; the active carbon nanotubes are prepared by dissolving a dispersant A into a solvent to obtain a dispersant solution, spraying the dispersant solution into carbon nanotubes stirred at a high speed through a high-pressure spraying method and stirring and mixing at a high speed. The polyethylene antistatic thin film disclosed by the invention is good in conductive property, high in antistatic durability and long in service life.

Owner:嘉兴高正新材料科技股份有限公司

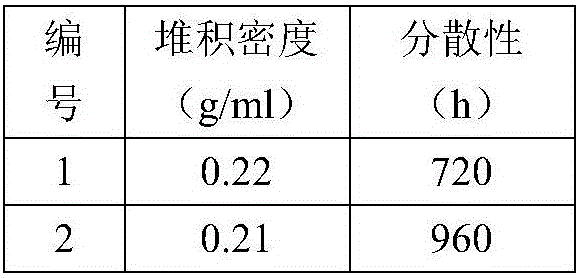

Wide-range titanium plate flaying polishing machine

ActiveCN104325370ANo protectionReduce noiseGrinding feedersPlane surface grinding machinesProduction rateEngineering

The invention provides a wide-range titanium plate flaying polishing machine which comprises a capsule body used for titanium plate polishing, a first sending device connected with the front end of the capsule body and a second sending device connected with the back end of the capsule body, wherein the capsule body is provided with a polishing platform, the polishing platform is provided with a polishing roller, a polishing roller driving system is directly fixed under the polishing roller, a pressing and rectifying roller used for fixing titanium plate type and maintaining the polishing flatness is arranged on the front end of the polishing roller, a temperature lowering system is arranged between the pressing and rectifying roller and the polishing roller, the temperature lowering system is connected to a water circulating system at the bottom part of the polishing platform, an in-capsule sending driving system is arranged at the bottom part of the capsule body and used for operating the polishing platform, and a dust removing device is arranged above the capsule body. All the devices are linked and work synchronously, the operation is controlled automatically by only one person, the device is an advanced and scientific panel surface mechanical processing device, the traditional manual grinding wheel polishing technology is completely changed, the product quality is good, and the labor production rate is greatly improved.

Owner:宝鸡市腾鑫钛业有限公司

Bromine erosion-preventing paint

InactiveCN1952026AStrong anti-corrosion abilityNo traceConjugated diene hydrocarbon coatingsAnti-corrosive paintsPolymer scienceBromine

The invention discloses a bromine corrosion prevention painting, which comprises the following parts: 48-55% dimethylbenzene, 45-50% 120# petrol, 6-8% DOP, 5-6% petrol resin, 6-10% butyl rubber and fitful dye. The preparing method comprises the following steps: putting dimethylbenzene and 120# petrol in the autoclave; blending 20min to mix evenly; adding DOP, petrol resin and butyl rubber; modifying with the speed at 2400-3000r / min for 2h; adding dye to stir at 3600-4000r / min; cutting at high speed to obtain the product with fineness at 60um; displaying aging-proof property and strong adhesion force.

Owner:邹文和

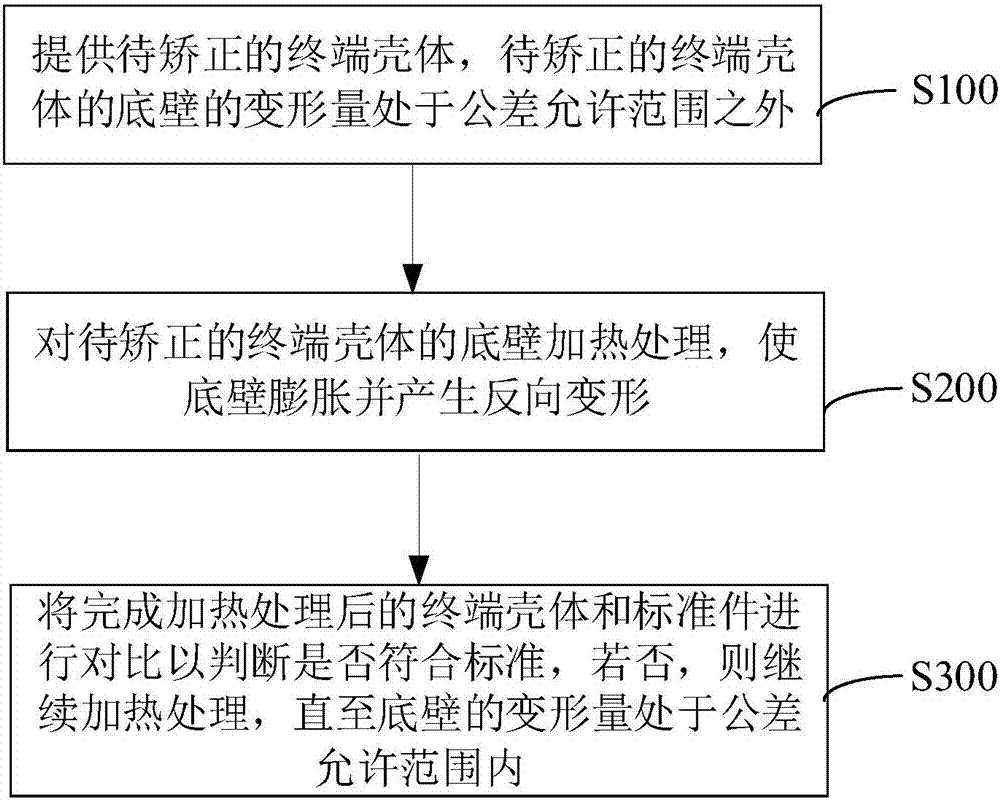

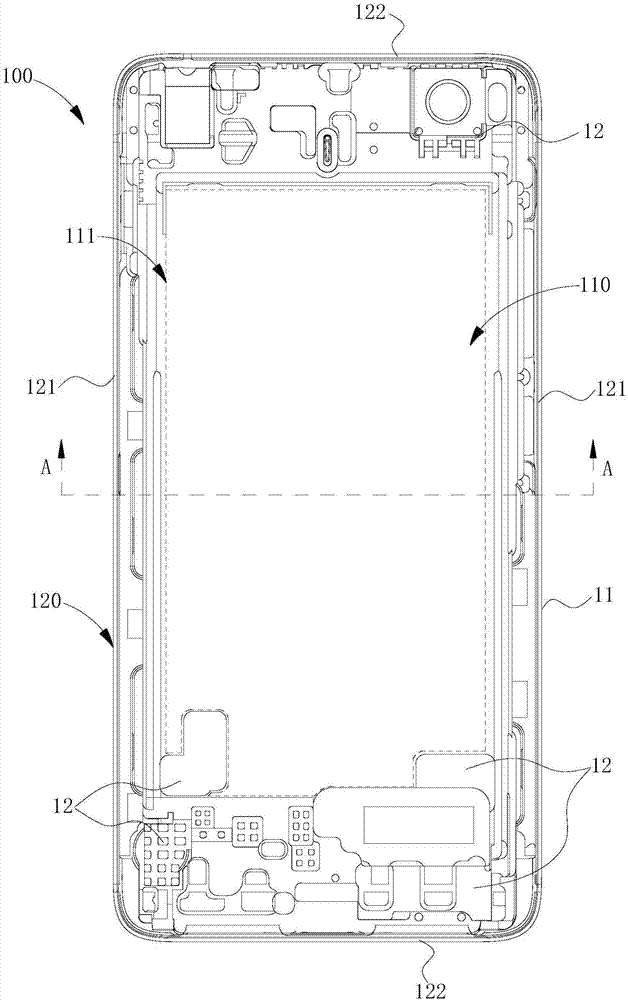

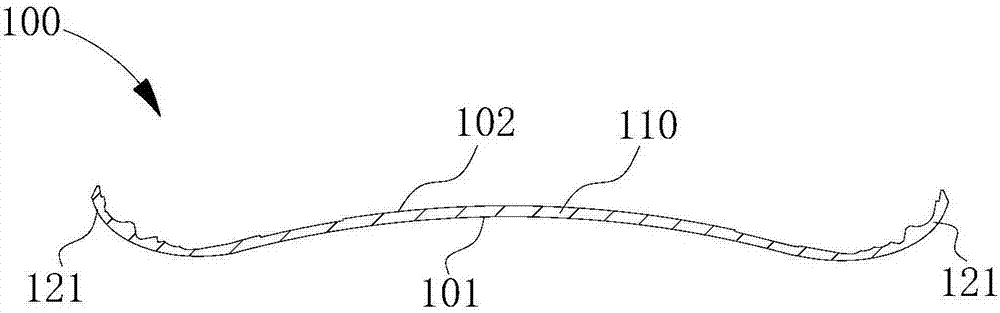

Terminal shell deformation correcting method

Owner:GUANGDONG EVERWIN PRECISION TECH

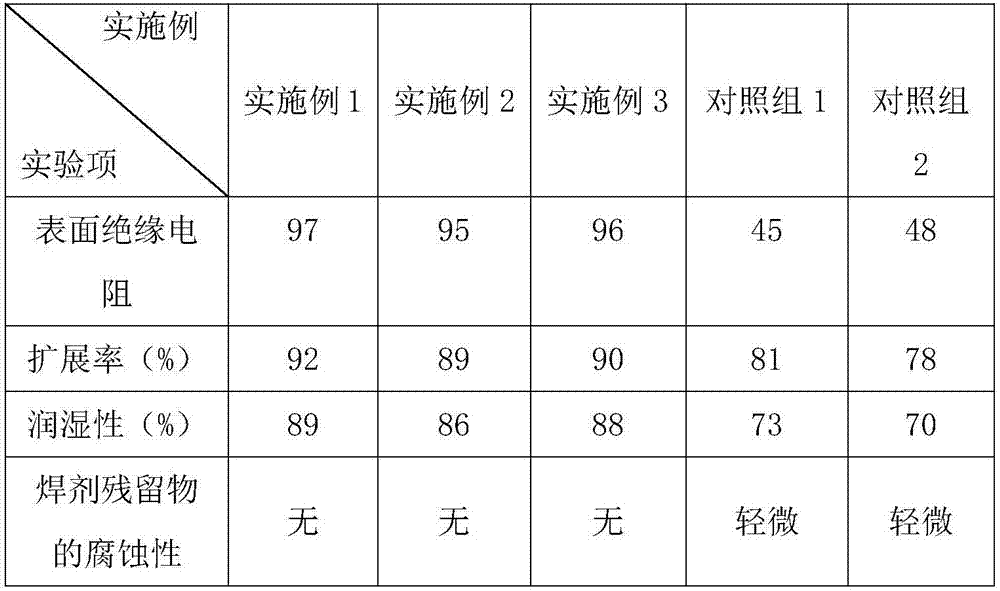

Efficient scaling powder and preparing method thereof

InactiveCN107175431AHigh activityGood soldering performanceWelding/cutting media/materialsSoldering mediaBenzimidazoleRosin

The invention discloses efficient scaling powder and a preparing method thereof. The efficient scaling powder is made of raw materials including polyacrylic acid, succinic acid, salicylic acid, 2-ethylhexyl epoxystearate, n-dodecanol ester, modified rosin, benzotriazole, benzimidazole, acrylic vinegar, acrylonitrile, benzyl alcohol, cyclohexanol, ethyl alcohol, a surface active agent, an antioxidant, nanosilicon dioxide, nano titanium dioxide and deionized water. The scaling powder is high in activity, the welding aid property is excellent, after welding, solid object is small in residue, cleaning is easy, the surface of a welded base body is transparent, clean and free of mark, the preparing method is simple, implementation is easy, and the powder is suitable for industrial production.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

Carbon nanotube modified polypropylene antistatic film

The invention discloses a carbon nanotube modified polypropylene antistatic film which is prepared by the following method: stirring carbon nanotube at high speed and simultaneously dissolving a dispersant in a liquid and spraying the liquid into the stirred carbon nanotube powder by a spraying mode to surface-activating the carbon nanotube, adding the active carbon nanotube used as a conductive filler into a PP material matrix to prepare PP / carbon nanotube conductive master batch with good conductivity, mixing the PP / carbon nanotube conductive master batch with PP matrix resin and a thermal-oxidative stabilizer, a flow modifier, an abrasive agent and other auxiliary agents, and preparing the polypropylene antistatic film by blow molding, tape-casting or two-way stretching technology. The prepared polypropylene antistatic film has good conductivity, strong antistatic endurance and long service life.

Owner:嘉兴高正新材料科技股份有限公司

Glasses

InactiveCN102736263AEasy loading and unloadingEasy to fixNon-optical partsUses eyeglassesEngineering

The invention provides a pair of smart glasses which can adjust length and width of the glasses freely without tools and can reduce the weight not contacting the face or even contacting the face, being characterized by inserting and fixing a fastener in an anti-skidding piece which is inserted and fixed with a glasses arms; being able to adjust the length from the frame to the arm sleeve by respectively adjusting the quantity for insertion of the glasses arms and the fastener relative to the anti-skidding piece; selecting the most suitable anti-skidding piece to fix to adjust the left and right interval of the anti-skidding piece; setting a freely bending guide piece on the extension cord for the glasses arms at the glasses arm side of the anti-skidding piece; inserting the glasses arms into the guide piece and the holde of the anti-skidding piece to bend the guide piece so as to perform deformation maintenance for the super elastic glasses arms; making the anti-skidding piece contact the upper side of the cheekbone to bear the weight of the glasses; making the arm sleeve contact the ear or the lateral head to prevent the frame skidding downward; setting heavy object in the arm sleeve, and adjustin the weight balance of the frame side through position sliding to get weight balance; and setting an exchangeable cover on the anti-skidding piece and the glasses arms to make a pair of smart glasses.

Owner:入江成夫

Novel glass super-hydrophobic transparent high-efficiency heat-insulating coating

PendingCN112322116AImprove insulation performanceImprove energy savingAntifouling/underwater paintsPaints with biocidesPROPYLENE GLYCOL BUTYL ETHERSlurry

The invention provides a novel glass super-hydrophobic transparent efficient heat-insulating coating and a preparation method thereof, and relates to the field of building materials, in particular tothe novel glass super-hydrophobic transparent efficient heat-insulating coating. The novel glass super-hydrophobic transparent high-efficiency heat-insulating coating comprises the following raw materials by weight: 2400 to 2600 kg of aqueous fluorocarbon resin (with solid content of 45 to 50%), 1200 to 1300 kg of slurry, 1100 to 1300 kg of deionized water, 130 to 160 kg of a 1053 dispersant, 50 to 70 kg of a DP082 antifoaming agent, 30 to 50 kg of a WT102 thickener, 80 to 100 kg of texanol, 90 to 110 kg of leveling agent and 4 to 6 kg of dipropylene glycol. The method comprises: uniformly mixing the water-based fluorocarbon resin with the slurry in proportion, then adding deionized water, a dispersing agent, an antifoaming agent, a thickener, texanol, leveling agent, dipropylene glycol monomethyl ether and dipropylene glycol butyl ether, adjusting the pH value to 7, and dispersing in a dispersion machine at a high speed of 1500 rpm for 30 min to obtain the glass super-hydrophobic transparent efficient heat-insulating coating.

Owner:成都享誉新材料科技有限公司

Activated carbon nanotube modified polypropylene (PP) antistatic film

The invention discloses an activated carbon nanotube modified polypropylene (PP) antistatic film. The PP antistatic film is prepared from the following components in parts by mass: 70-95 parts of PP base materials, 0.01-10 parts of activated carbon nanotubes and 0.1-20 parts of an aid, wherein the aid is one or a mixture of two or more of a dispersant B, a coupling agent, an antioxidant, a lubricant and an abrasive agent; an activated carbon nanotube is prepared through the following steps: the dispersant A is dissolved in a solvent, and a dispersant solution is obtained; then, the dispersant solution is sprayed into the carbon nanotube stirred at a high speed with a high pressure spray method, and the activated carbon nanotube is prepared after high-speed stirring and mixing. The PP antistatic film has good conductivity, high antistatic durability and long service life.

Owner:嘉兴高正新材料科技股份有限公司

Naevus removing ointment

InactiveCN1736397AGood treatment effectEasy to useDermatological disorderPlant ingredientsCamphorYunnan Baiyao

Owner:赵艳英

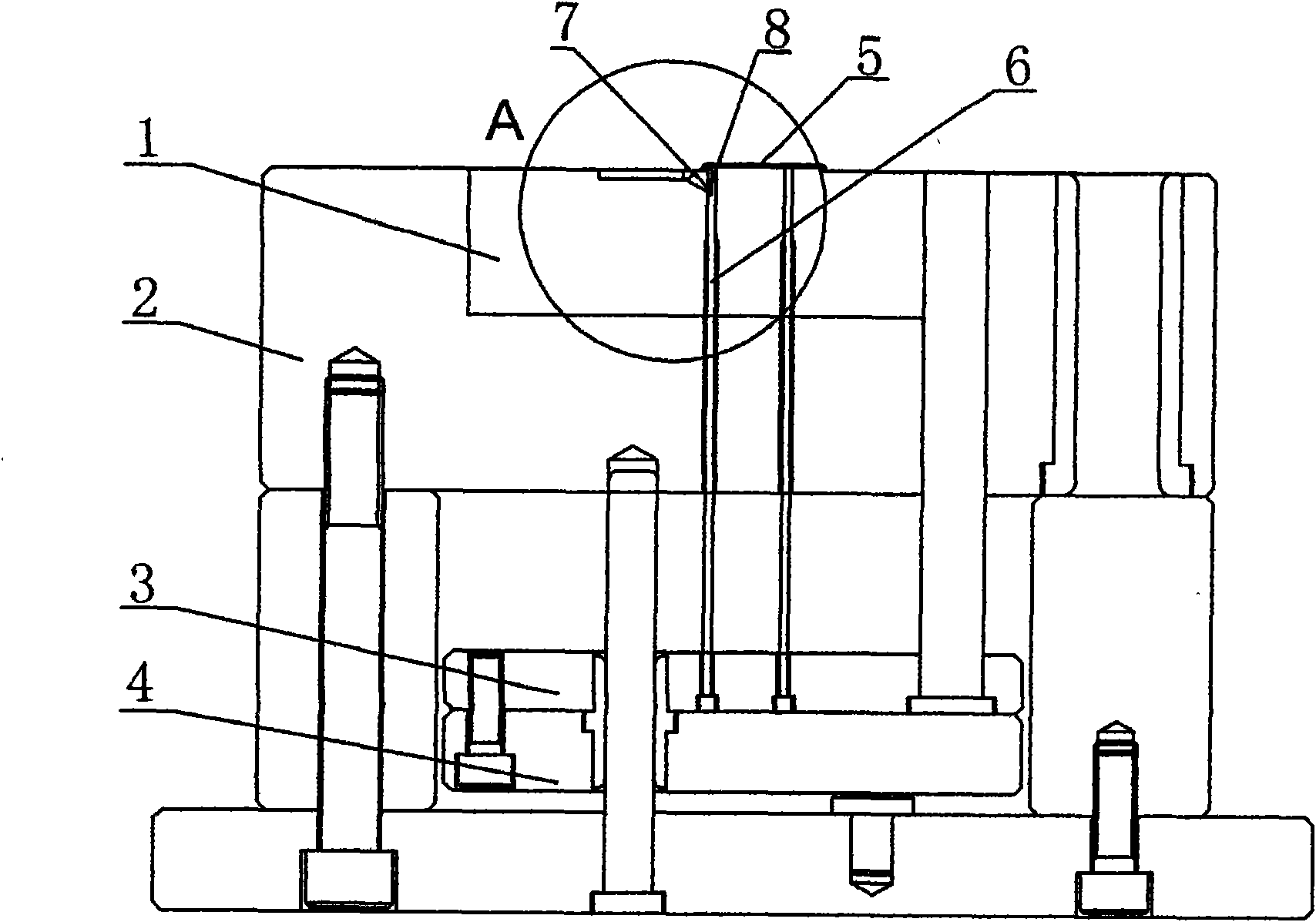

Carrier rod type gate for injection mold

Owner:TIANJIN ZHONGHUAN SANFENG ELECTRONICS

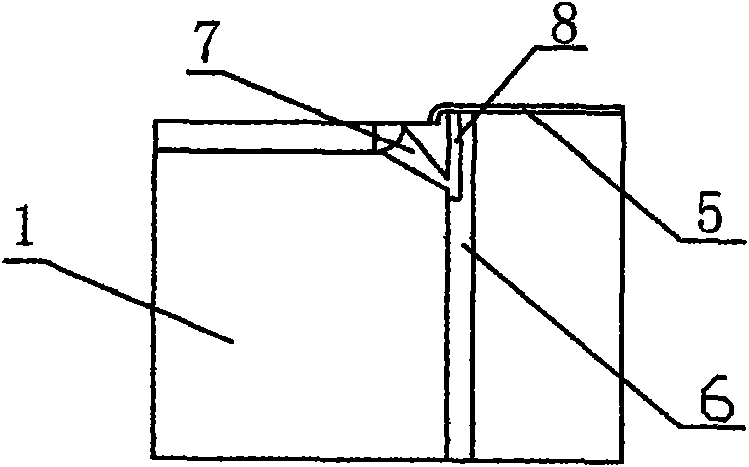

Aluminium alloy material and preparation method thereof

The invention discloses an aluminium alloy material and a preparation method thereof. The aluminium alloy material comprises the following steps by weight percent: 3%-10% of zinc, 0.5%-3% of magnesium, 0.1%-0.5% of copper, less than 0.1% of silicon, less than 0.2% of iron, less than 0.15% of chromium, less than 0.03% of titanium, less than 0.15% of total impurities (with less than 0.05% of singe impurity element) and the balance of aluminum.

Owner:GOERTEK INC

Brake valve cleaning fluid and preparation method thereof

InactiveCN111961539AEasy to useMild performanceInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSilicone fluidSodium silicate

The invention discloses a brake valve cleaning fluid is prepared from the following components in parts by weight: 2-8 parts of alkyl sodium sulfonate, 1-5 parts of sodium silicate, 0.5-1 part of paraben, 0.5-1 part of simethicone, 0.5-2 parts of alkyl glycoside, 20-30 parts of ethanol, 60-70 parts of isopropanol and 30-40 parts of deionized water. The invention further discloses a preparation method of the brake valve cleaning fluid. The preparation method comprises the steps of weighing and mixing. The cleaning fluid provided by the invention is convenient to use, has the characteristics ofbiodegradability, mild performance, corrosion resistance, bacteria resistance and no trace after being wiped, particularly has good compatibility to plastic products, and is suitable for surface cleaning of metal and plastic products.

Owner:哈尔滨铁路石化销售有限公司

Whiteboard and manufacturing process thereof

ActiveCN109249657AThe preparation process steps are simpleEasy to operate and controlLamination ancillary operationsPolyureas/polyurethane adhesivesWhiteboardEngineering

The invention relates to the technical field of office stationery, and especially to a whiteboard and a manufacturing process thereof. The manufacturing process comprises the following steps: (1) taking a wood board, applying a layer of glue on one side of the wood board, and then sticking iron sheet; (2) pressing the wood board and the iron sheet with a pressure of 5-15 kg force for 2-4 days so as to obtain an adhesive board; (3) sealing the edge of the adhesive board with hot melt adhesive, and then fixing with a frame, coating the outer surface of the iron sheet with a layer of paint whichis easy to write and erase so as to make a whiteboard. The whiteboard prepared by the invention has the advantages of simple structure, easy inking, good repeated writing and wiping function, no colorstickiness, no discoloration, no dust, no trace, good scratch resistance and environmental protection.

Owner:东莞市澳星视听器材有限公司

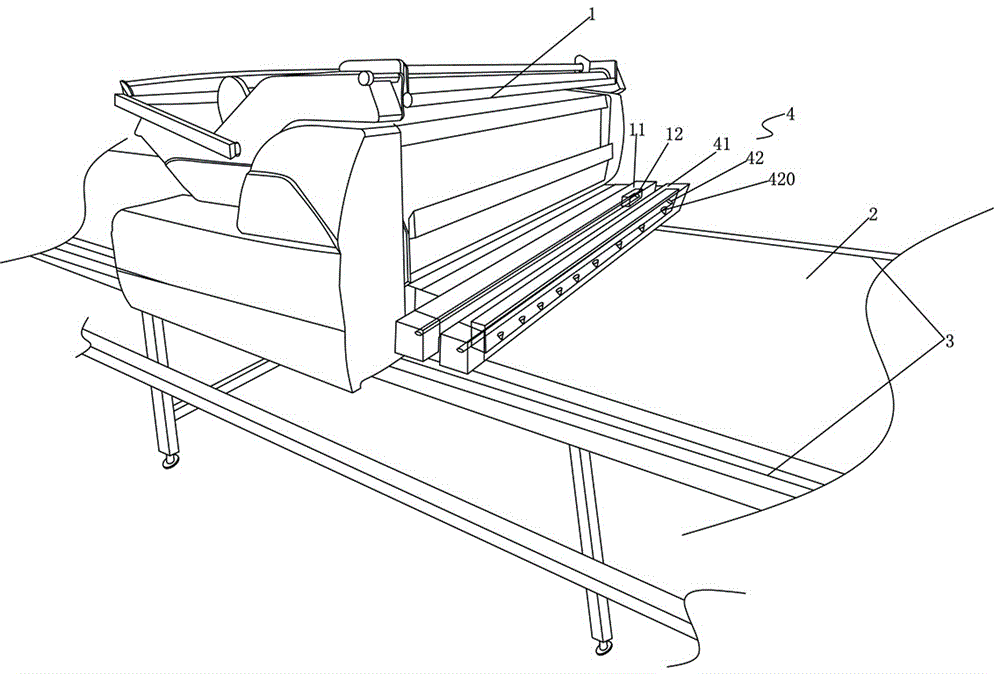

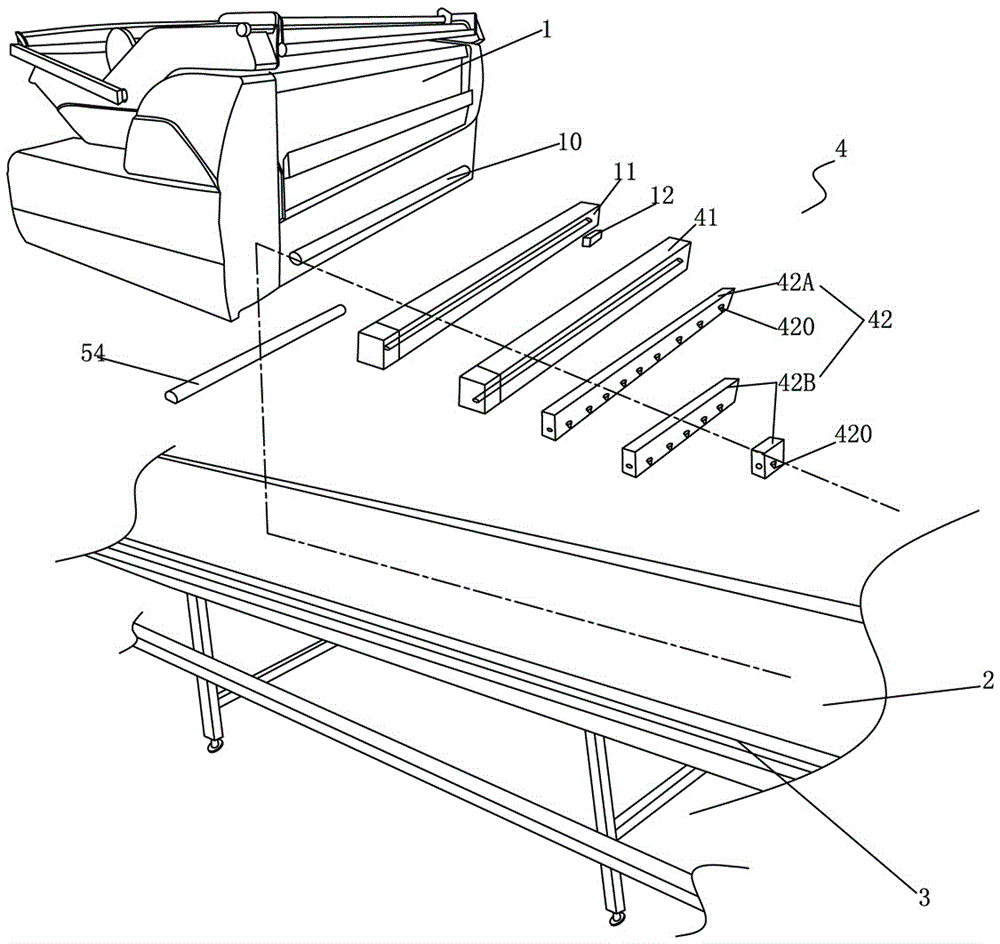

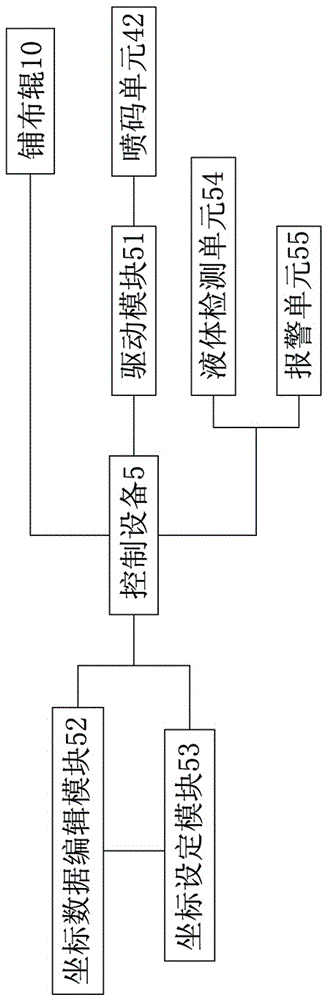

Cloth paving device with code spraying function and method thereof

The invention discloses a cloth paving device with a code spraying function. The device comprises a cloth paver and a platform, wherein conveying rails on which the paver slides and paves the cloth are formed on two sides of the platform; the cloth paver is provided with a cloth paving roller, a first sliding rail and a cloth cutting unit; the cloth paving roller and the first sliding rail are arranged corresponding to a width direction between the two conveying rails; the cloth cutting unit slides along the first sliding rail; the device also comprises a code spraying assembly arranged at the front end of the cloth cutting unit; the code spraying assembly comprises a second sliding rail, a code spraying unit and a control device; the second sliding rail is parallel to the first sliding rail; the code spraying unit is connected to the second sliding rail and slides along the second sliding rail; the control device is electrically connected to the cloth paver, the cloth cutting unit and the code spraying unit respectively. Through the cloth paving device and a method thereof, the code can be automatically sprayed; the encoding efficiency and accuracy are greatly improved; liquid capable of being heated to volatilize is used as encoding liquid; the encoding liquid is traceless and damage-free after being heated to volatilize in water; the requirements of actual production can be easily met.

Owner:FUJIAN SEVEN FASHION TECH CO LTD

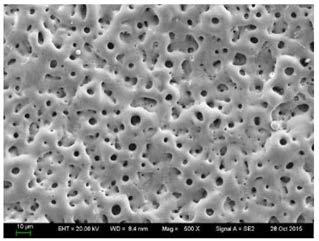

Large-size titanium alloy structure micro-arc oxidation based on scanning cathode and verification method

InactiveCN109537022ANo tracePhenomena that control ablationSurface reaction electrolytic coatingMicro arc oxidationValidation methods

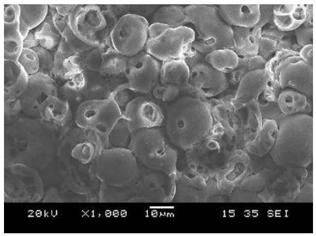

The invention discloses a large-size titanium alloy structure micro-arc oxidation based on scanning cathode and an experimental verification method thereof. Through theoretical design and experimentalresearch and other manners, a large-size titanium alloy structure surface one-time micro-arc oxidation technology is achieved, the key technologies of scanning cathode device design, one-time large-area micro-arc oxidation technical process regulation and control and the like are achieved, thereby solving the problems of micro-arc oxidation process and film surface quality of large-size structural parts and improving the capacity of one-time area treatment to be more than 4m<2>, the oxidation efficiency is greatly improved, and a foundation is laid for micro-arc oxidation treatment on the surfaces of light alloy large-sized parts, such as aluminum alloy, magnesium alloy and the like, and complex parts.

Owner:CHINA SPECIAL TYPE FLIER RES INST

A High Performance Flux

ActiveCN104439757BHigh activityReduce surface tensionWelding/cutting media/materialsSoldering mediaGlutaric acidPolyethylene glycol

The invention discloses a high-performance soldering flux. The high-performance soldering flux comprises the following ingredients in parts by weight: 3-8 parts of citric acid, 2-6 parts of glutaric acid, 2-6 parts of triisopropanolamine, 1-3 parts of triethanolamine, 12-25 parts of modified rosin, 0.8-2 parts of surfactant, 0.3-0.8 part of benzotriazole, 1-2.8 parts of nano-silver, 0.2-0.9 part of nano-titanium, 0.1-0.5 part of benzimidazole, 2-7 parts of 2-(2-Ethoxyethoxy)ethanol, 3-8 parts of nitroethane, 1-5 parts of glycerin monostearate, 2-4.5 parts of pentaerythritol oleate, 0.3-1 part of dodecanedioic acid, 0.3-0.9 part of polyamide modified hydrogenated castor oil, 0.3-2 parts of polyethylene glycol, 50-120 parts of ethyl alcohol and 200-300 parts of water. The high-performance soldering flux is high in activity, excellent in soldering performance and easy to clean; little residues are generated after the high-performance soldering flux is used.

Owner:TIANCHANG FEILONG BRAND STEEL GRID

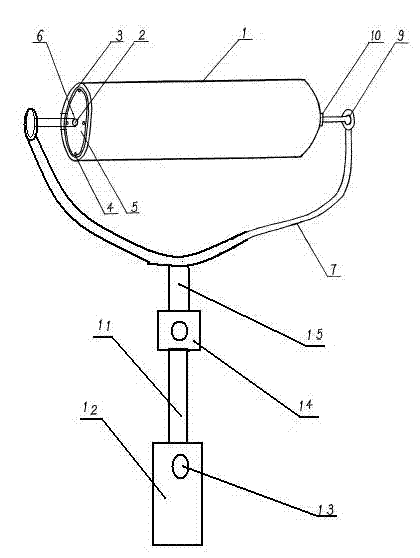

Novel paint brushing device

InactiveCN104741281ASimple structureEasy to useLiquid surface applicatorsCoatingsBrush deviceEngineering

The invention discloses a novel paint brushing device which comprises a sponge roller body outer layer, a center rotating shaft, a plastic sleeve, a supporting rod and a telescopic brush rod. The plastic sleeve is arranged in the sponge roller body outer layer, and supporting ribs are arranged in the plastic sleeve. The two ends of the center rotating shaft are positioned at corresponding circular positioning disk center holes. The upper ends of the supporting rod which are matched with the rotating shaft in a rotating mode are provided with sealing bearings, and baffle rings are arranged on the outer sides of a roller body at the ends of the center rotating shaft to prevent the roller body from sliding left and right. A gasket is arranged on the inner side of each baffle ring, and a brush handle is arranged at the lower end of the supporting rod. A fixed sleeve is arranged at the lower end of the brush handle, and the telescopic brush rod is arranged in the fixed sleeve. The paint brushing device has the advantages that the structure is simple; using is convenient; the design of the sponge roller body outer layer is adopted so that paint is brushed evenly, flatly and attractively without lumps or traces; no power source is needed in operation, and the device is light, handy, smooth, quick, solid, durable, capable of saving labor and materials, capable of achieving the objective of energy efficiency and avoiding waste; the using cost is low, the application range is wide, and the device has a bright market prospect.

Owner:TIANJIN JINGPIN HUIDA RADIATOR CO LTD

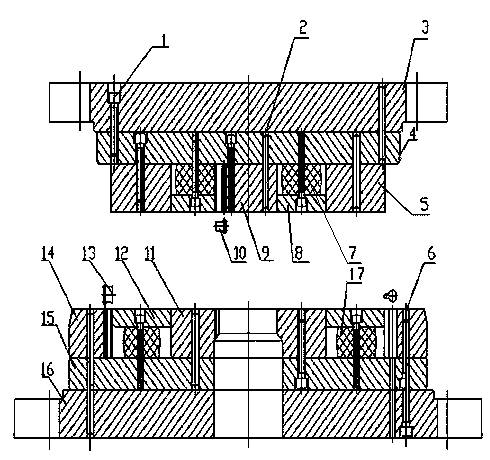

Blanking mold of motor stator punching sheet with sheet buckling groove

InactiveCN104384326AReduce investmentIncrease productivityShaping toolsStripping-off devicesPunchingEngineering

The invention discloses a blanking mold of motor stator punching sheet with a sheet buckling groove. The blanking mold comprises an upper concave-convex mold and a lower concave-convex mold, wherein the middle of the upper concave-convex mold is provided with a rotor shaft hole male mold, a rotor key groove mold is arranged along the circumferential direction of the rotor shaft hole male mold, an upper concave ring is arranged around the outer side of the rotor shaft hole male mold, an upper elastic pad block is arranged in the upper concave ring, the lower side of the upper elastic pad block is connected with an upper discharging plate, the middle of the lower concave-convex mold is provided with a shaft hole in a position corresponding to the rotor shaft hole male mold, a stator excircle male mold is arranged at the excircle part of the lower concave-convex mold, a stator sheet buckling groove male mold is arranged along the inner diameter part of the stator excircle male mold, a lower concave ring is arranged around the outer side of the shaft hole, a lower elastic pad block is arranged in the lower concave ring, a lower discharging plate is connected onto the lower elastic pad block, and a sign groove male mold is also arranged on the lower concave-convex mold. Compared with the prior art, the blanking mold has the beneficial effects that the stator blanking and the processing in the buckling sheet groove can be simultaneously completed on one mold, and the work efficiency is improved.

Owner:JIANGSU TONGDA POWER TECH

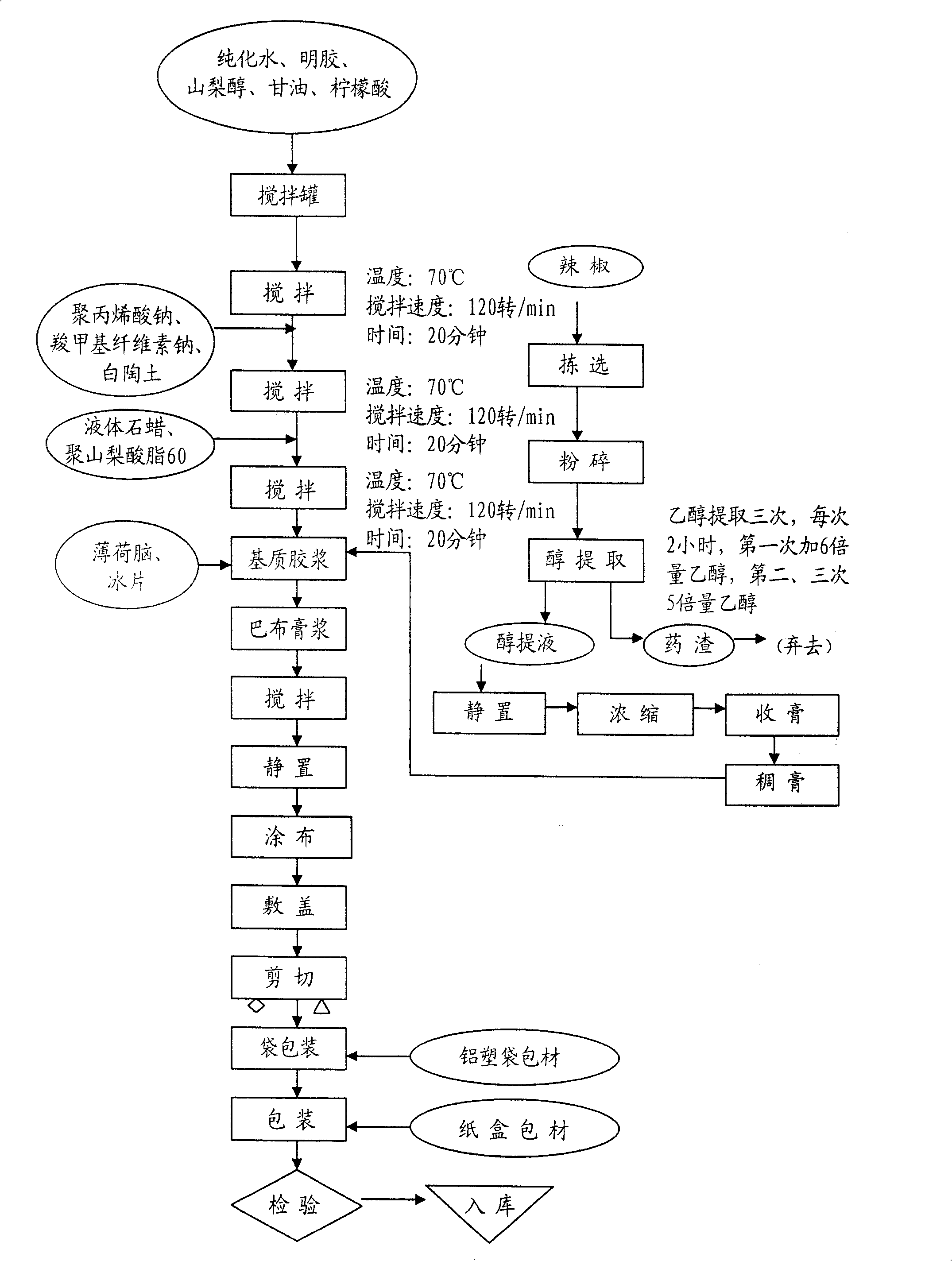

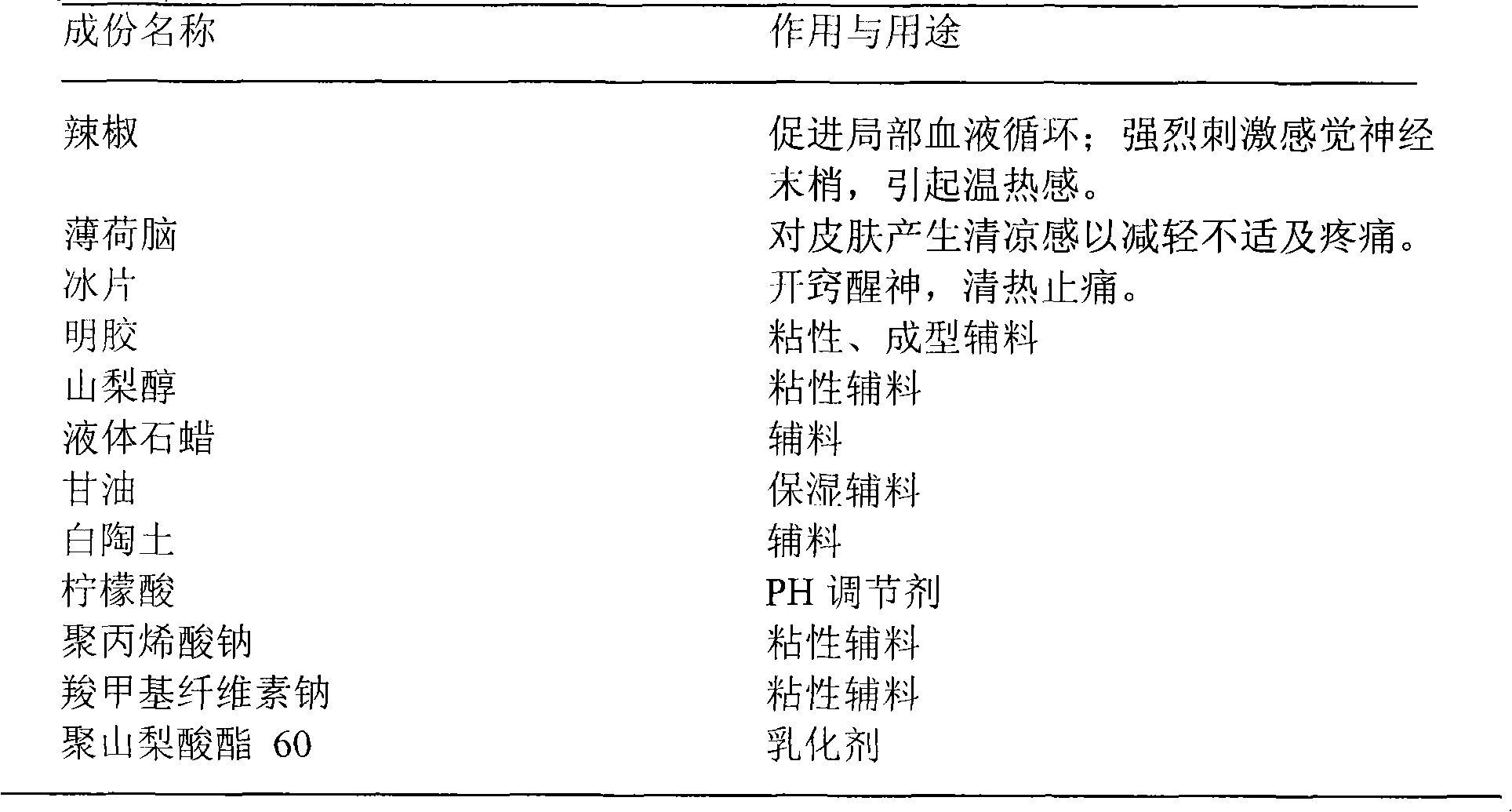

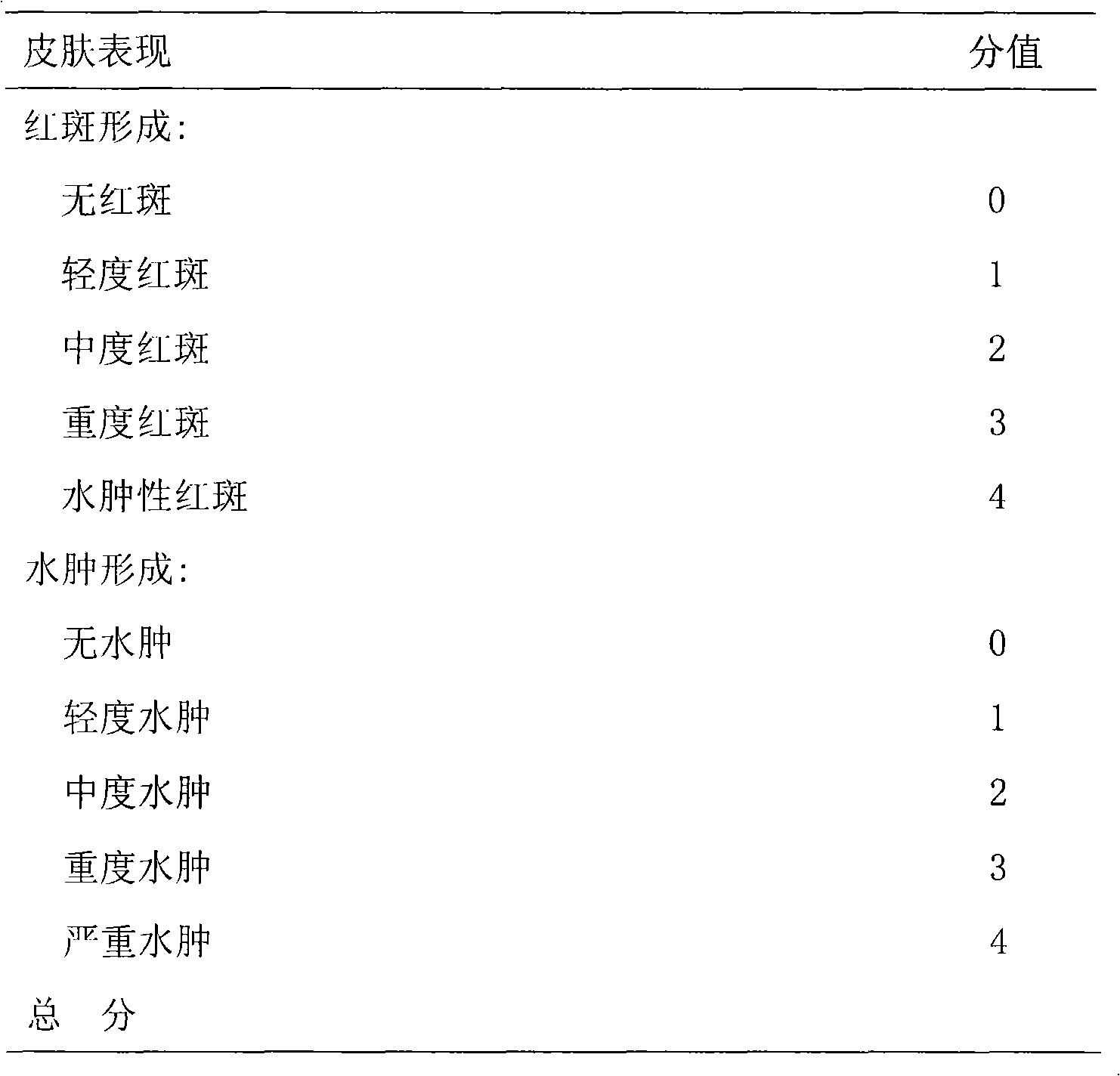

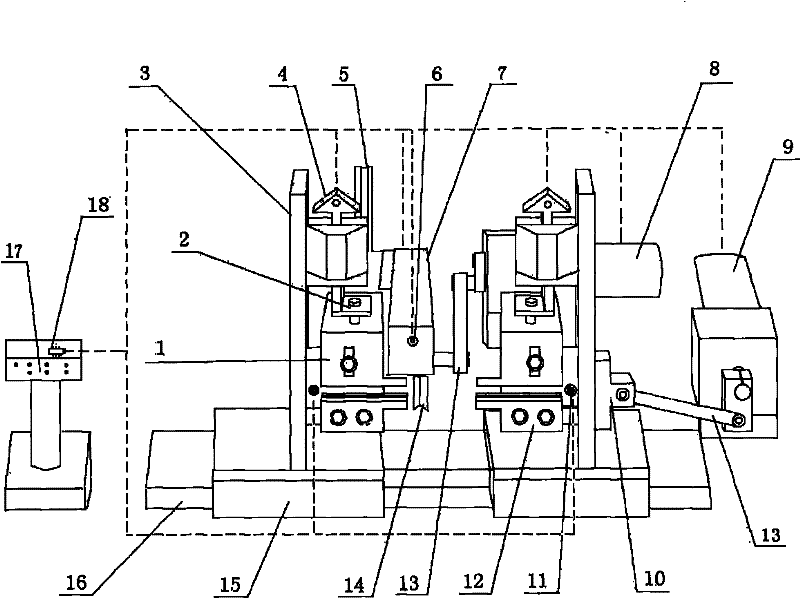

Pepper Babu plaster for rheumatism and method for producing the same

ActiveCN101406565APromote absorptionNo traceHydroxy compound active ingredientsAntipyreticMentholCapsicum extract

The invention provides a capsicum rheumatism babu paste and a producing method thereof. The invention solves the technical problems: a rubber paste has the defects of stimulating skin, having poor ventilation property, aching in tearing off a drug cloth, remaining marks in skin and the like and brings pain to patients. The invention comprises the following main points: a medicine extract of the babu paste is a capsicum extract; chemical medicines are menthol and borneol; and substrates of the babu paste are an adhesive, a humectant and an excipient. The paste has the following applications: the capsicum rheumatism babu paste is used for arthralgia, the ache of waist and back, sprain, stasis, swellings, chornic arthritis, non-ulcerated chilblain and the like.

Owner:SHENYANG HONGYAO GRP CO LTD

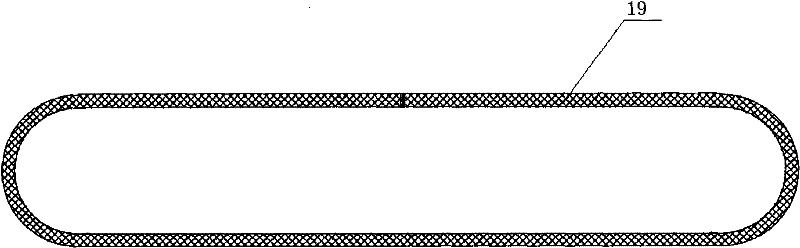

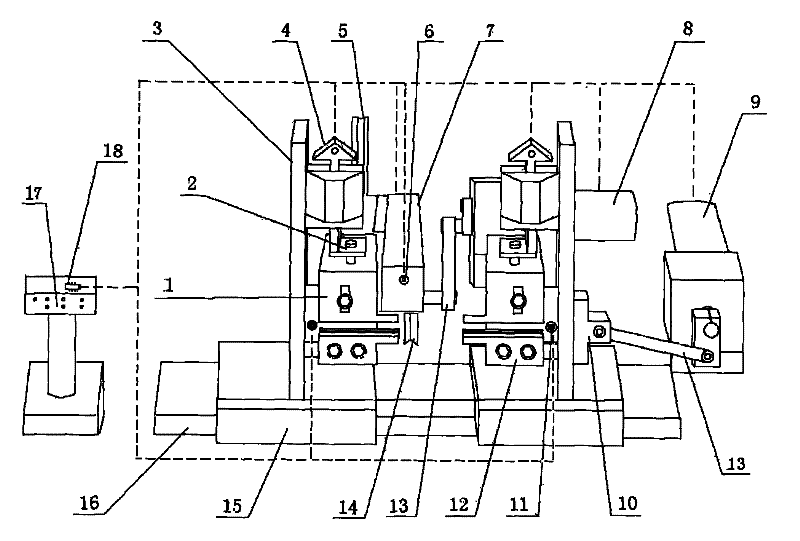

Electronic-control endless rope production equipment

InactiveCN101666049BImprove efficiencyQuality improvementRope making machinesExtensibilityAutomatic control

Owner:余建鸣

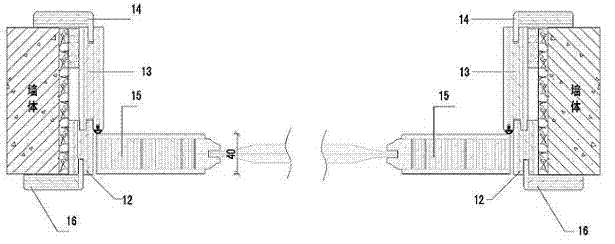

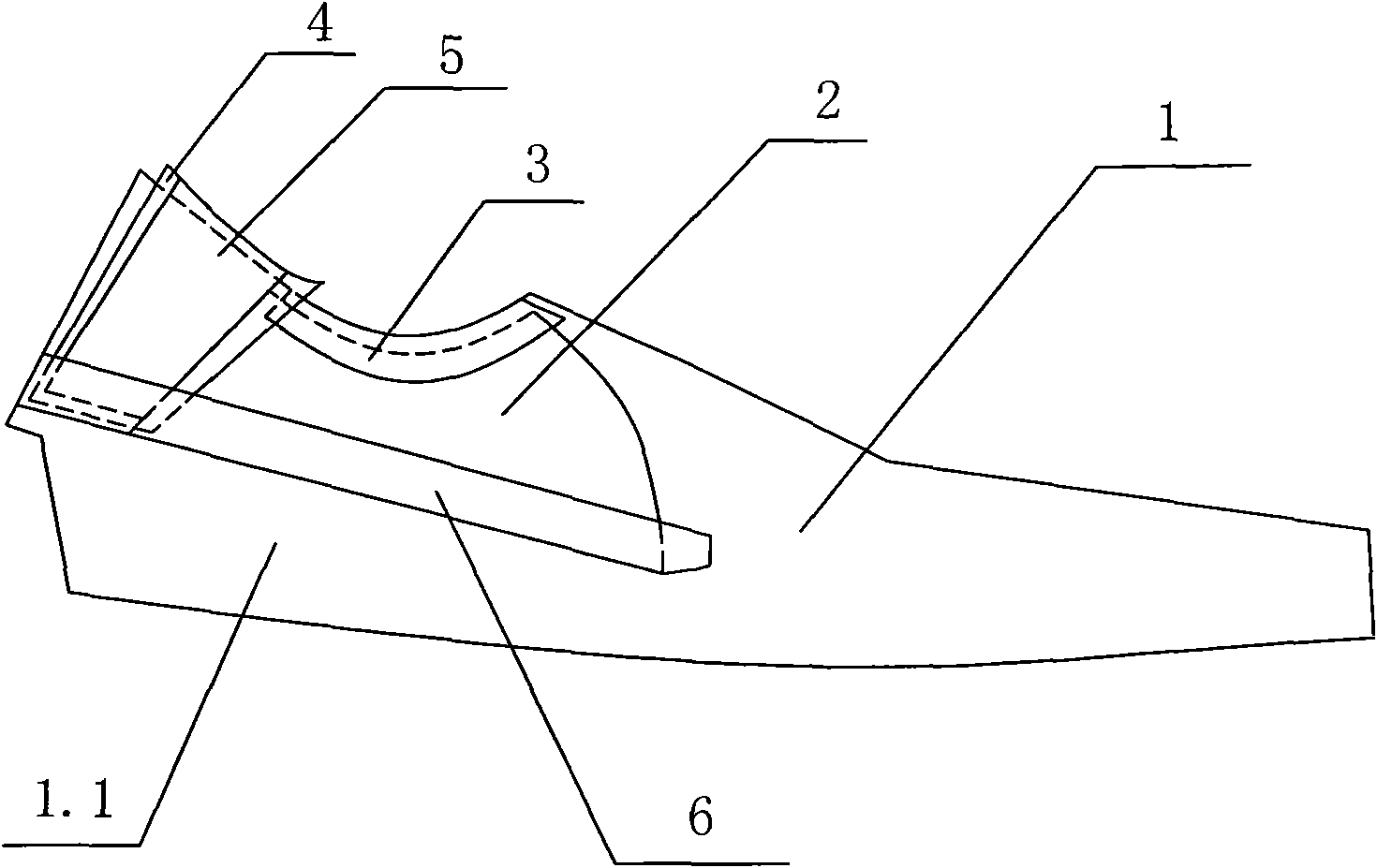

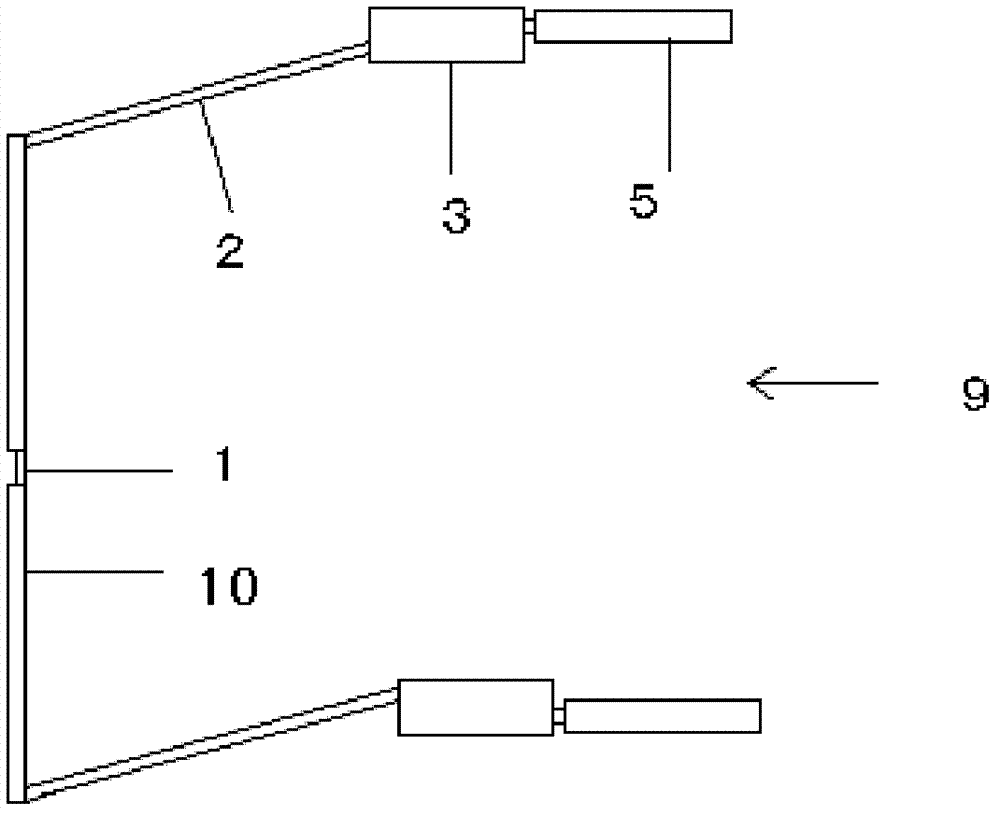

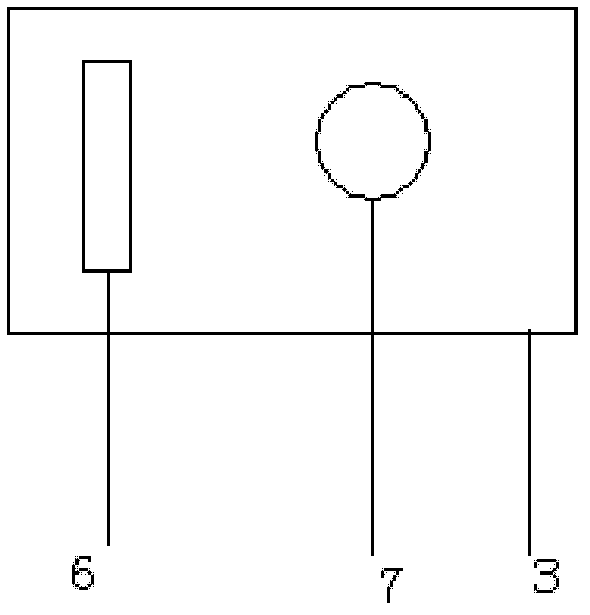

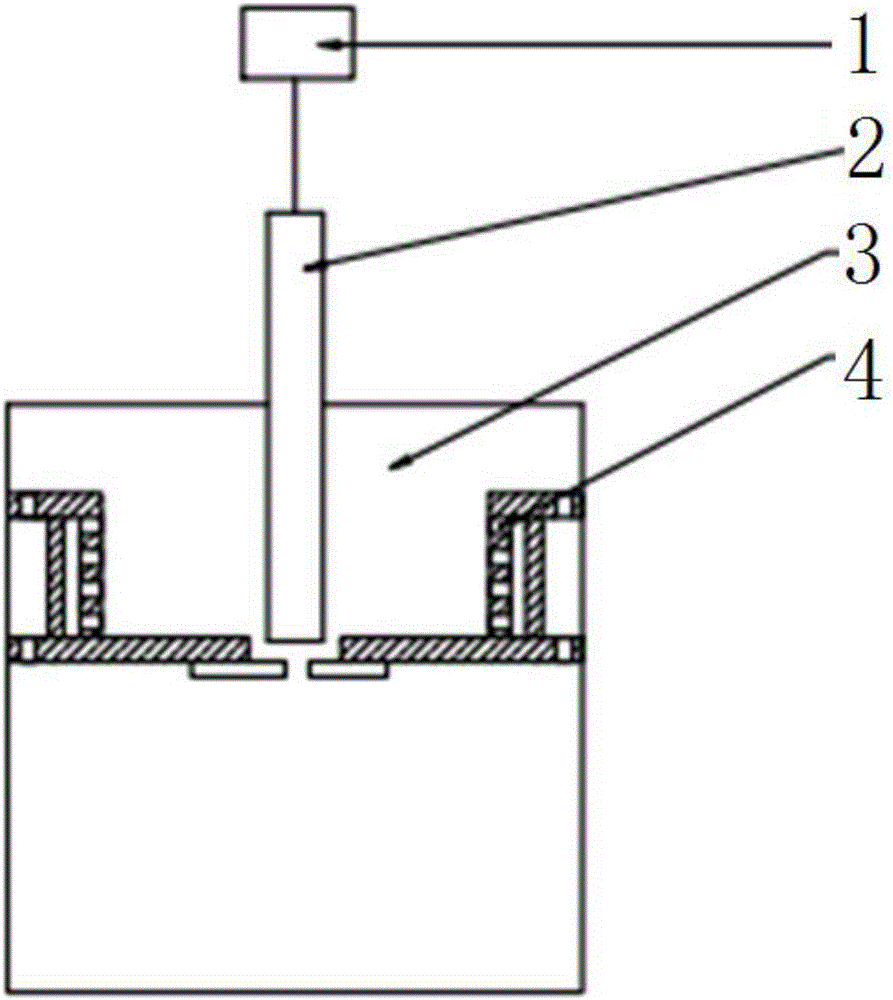

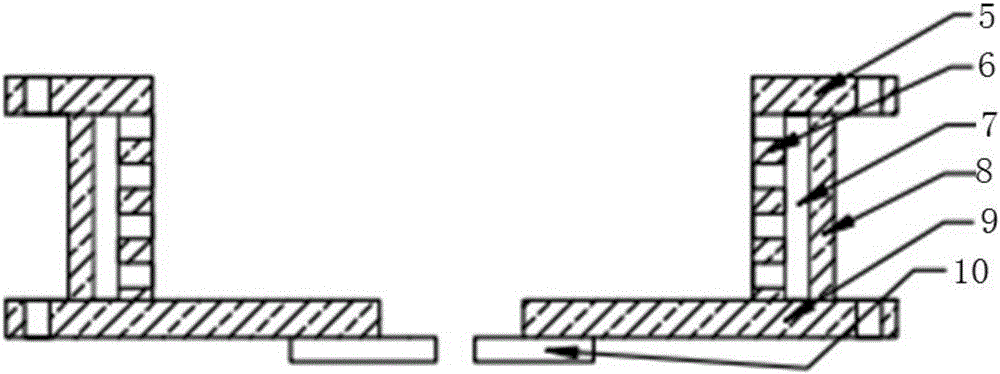

Titanium alloy component print-free micro-arc oxidation treatment device

ActiveCN106498479ASimple compositionReduce maintenance costsSurface reaction electrolytic coatingMicro arc oxidationTitanium alloy

The invention provides a titanium alloy component print-free micro-arc oxidation treatment device. The device comprises an electrolytic cell, a lifter and a cathode assembly. The cathode assembly comprises cathodes, a guard plate assembly and flexible sealing rubber plates. The cathodes are mounted in the guard plate assembly and located on the two sides of a titanium alloy component descending path. Upper guard plates, rear guard plates and lower guard plates close the upper surfaces, the lower surfaces and the side faces, back to the titanium alloy component descending path, of the cathodes. Hollowed-out front guard plates are fixed to the side faces, facing the titanium alloy component descending path, of the cathodes. Hollowed-out holes are uniformly formed in the hollowed-out front guard plates. The hollowed-out area is set according to the requirement for the electric field intensity. The flexible sealing rubber plates are fixed to the front ends of the two lower guard plates. When the lifter can drive a titanium alloy component to descend, the flexible sealing rubber plates are attached to the titanium alloy component to enable the oxidized titanium alloy component to be partially separated from the electric field. According to the titanium alloy component print-free micro-arc oxidation treatment device, sheet-like open type cathodes are changed into the cathodes with the closed lower portions, and oxidized titanium alloy is made to be separated from the electric field. Consequently, energy is saved, and erosion of titanium alloy can be effectively prevented.

Owner:CHINA SPECIAL TYPE FLIER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com