Carbon nanotube modified PET antistatic thin film

A carbon nanotube modification and carbon nanotube technology, which is applied in the field of PET antistatic film, can solve the problems of quality degradation, poor adhesion, sticky return, etc., and achieve the effect of no trace, no black spot, and no protrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

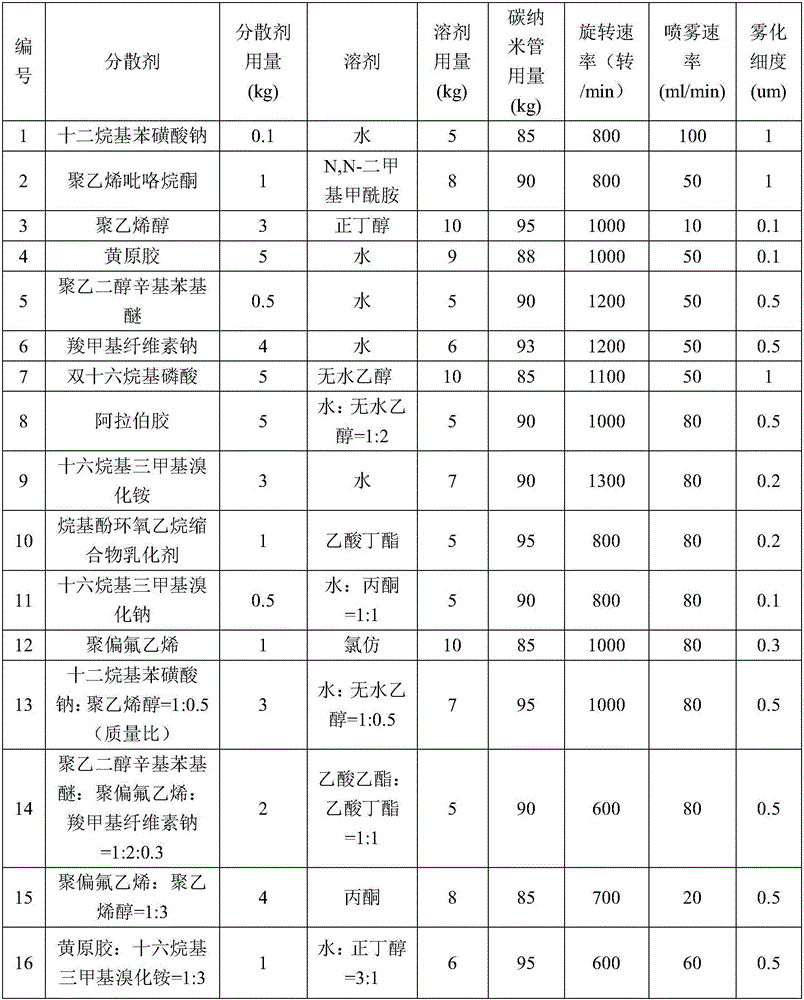

[0046] Take the raw materials in Table 1 below, dissolve the dispersant in the solvent to obtain a dispersant solution, and then spray the dispersant solution into high-speed stirred carbon nanotubes (diameter 1-30 nm, length 1-100 μm, bulk density 0.02g / mL), process parameters are as shown in table 1, after high-speed stirring and mixing, activated carbon nanotubes are obtained;

[0047] Table 1

[0048]

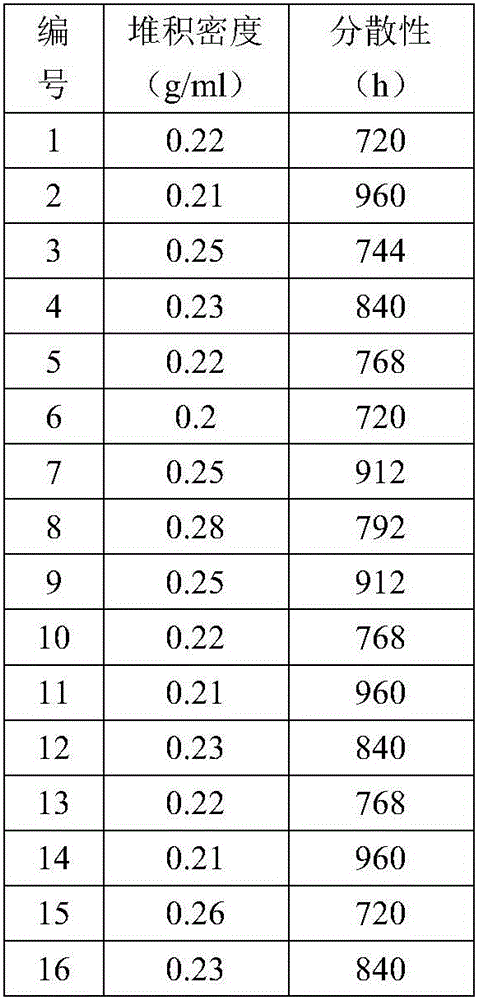

[0049] The performance test result of the prepared activated carbon nanotube is as follows table 2

[0050] Table 2

[0051]

[0052] The dispersibility experiment is detected by the following method: 10 mg of activated carbon nanotubes prepared in Examples 1 to 16 are added to 10 mL of the solvent (see Table 1) used to prepare the activated carbon nanotubes, and ultrasonically dispersed for 30 minutes to obtain a suspension solution, stand still, and when obvious stratification occurs, the recorded time is the storage time, and the results are shown in Table 2. Th...

Embodiment 17~32

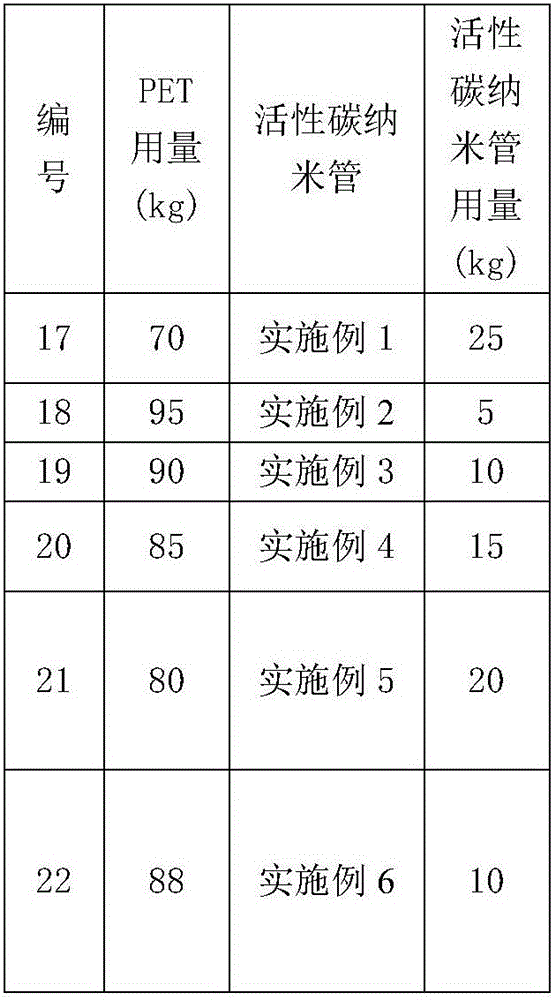

[0055] Stir and mix the activated carbon nanotubes prepared in Examples 1 to 16 with PET polymer powder (average particle diameter 100 μm to 2 mm), see Table 3 for the dosage, then mix with the additives in Table 4, and extrude through twin-screw The PET / carbon nanotube conductive masterbatch was obtained by machine melt extrusion, stretching, cooling and pelletizing; the processing technology of the twin-screw extruder was 200r / min, and the extrusion temperature was 255°C.

[0056] The carbon nanotube content of the prepared PET / carbon nanotube conductive masterbatch is shown in Table 5.

[0057] Mix the prepared PET / carbon nanotube conductive masterbatch with the PET substrate and various additives according to the formula in Table 5, and make an antistatic film through biaxial stretching. and Surface Resistivity Test Method "test the surface resistivity of the film, and detect its physical properties, the results are shown in Table 6.

[0058] table 3

[0059]

[0060]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com