Electronic-control endless rope production equipment

A production equipment and circulating rope technology, applied in textile cables, rope-making auxiliary devices, textiles and papermaking, etc., can solve problems such as unstable batch product quality, and achieve high pass rate, no discoloration, concentric and uniform effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

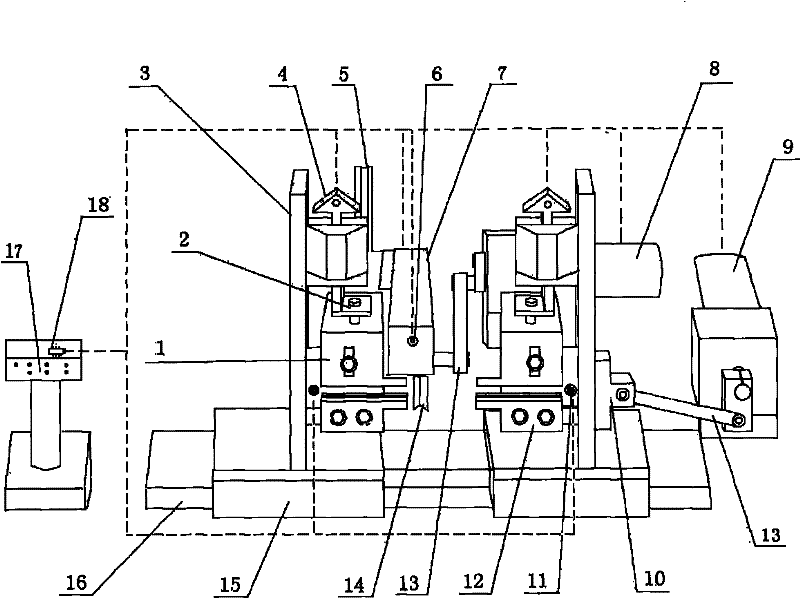

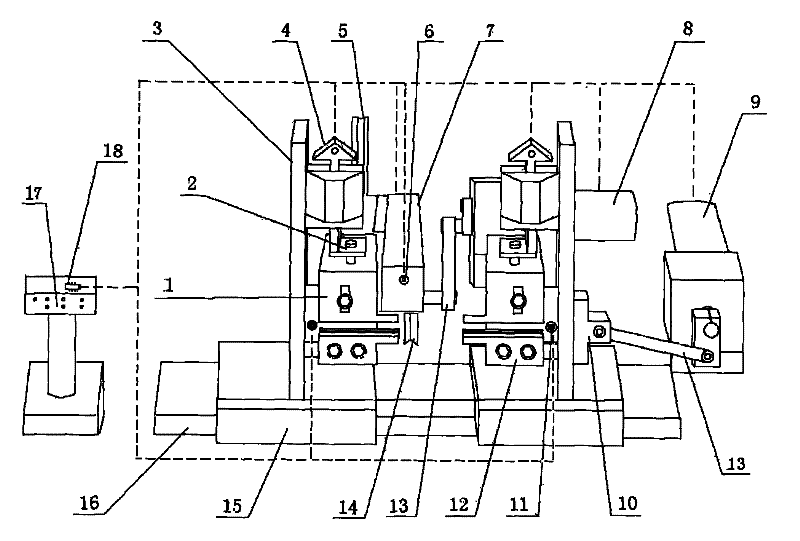

[0016] The accompanying drawings show the best embodiment of the electronically controlled circulating rope production equipment of the present invention. As shown in the figure, the preferred embodiment of the electronically controlled circulating rope production equipment of the present invention has a base slideway 16 at the bottom, and two base slide blocks 15 that can move laterally along the slideway are installed on the slideway. The base 3 is fixed on the base slider 15 . The upper and lower parts 1 and 12 of the fixture are connected with the base 3 to realize an indirect connection with the base slider 15 . The upper end of the adjusting plate 2 is connected with the electromagnet 4, and the lower end is connected with the upper half part 1 of the fixture. The electromagnet 4 adjusts the clamping degree of the upper and lower parts 1 and 12 of the clamp to the wire rope by controlling the adjustment plate 2 . A connecting rod seat 10 is housed on the base 3 on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com