Cloth paving device with code spraying function and method thereof

A coding and cloth spreading technology, which is applied in the field of clothing, can solve the problems that the surface cannot be smooth and smooth, the aesthetic function cannot be achieved, and the cloth is not easy to be mixed together, so as to ensure the stability and effectiveness of production, improve flexibility and Operability, the effect of avoiding manual coding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

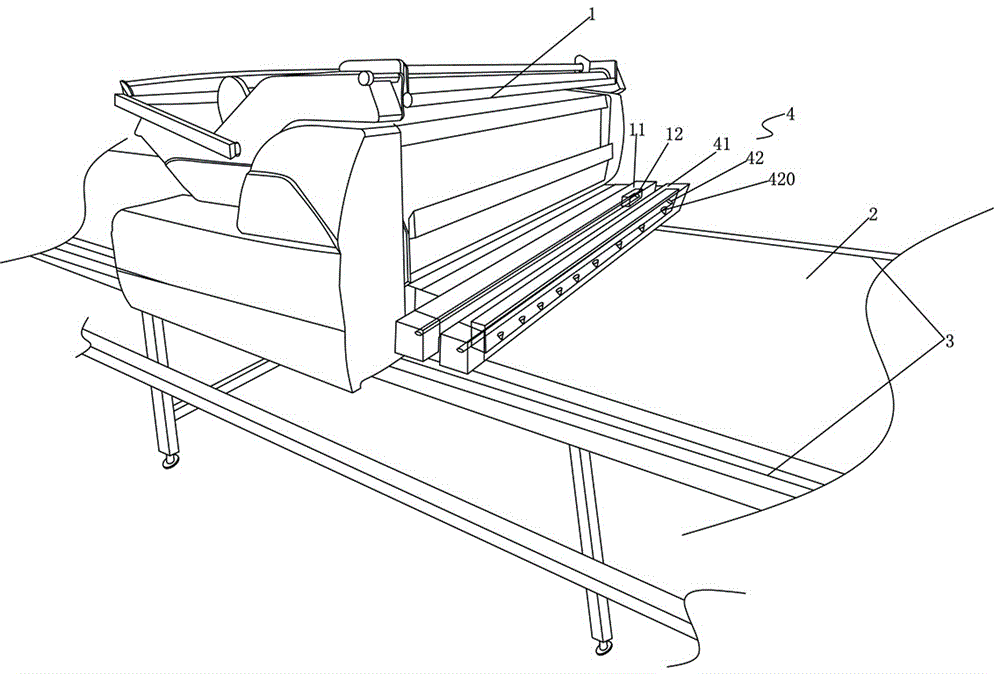

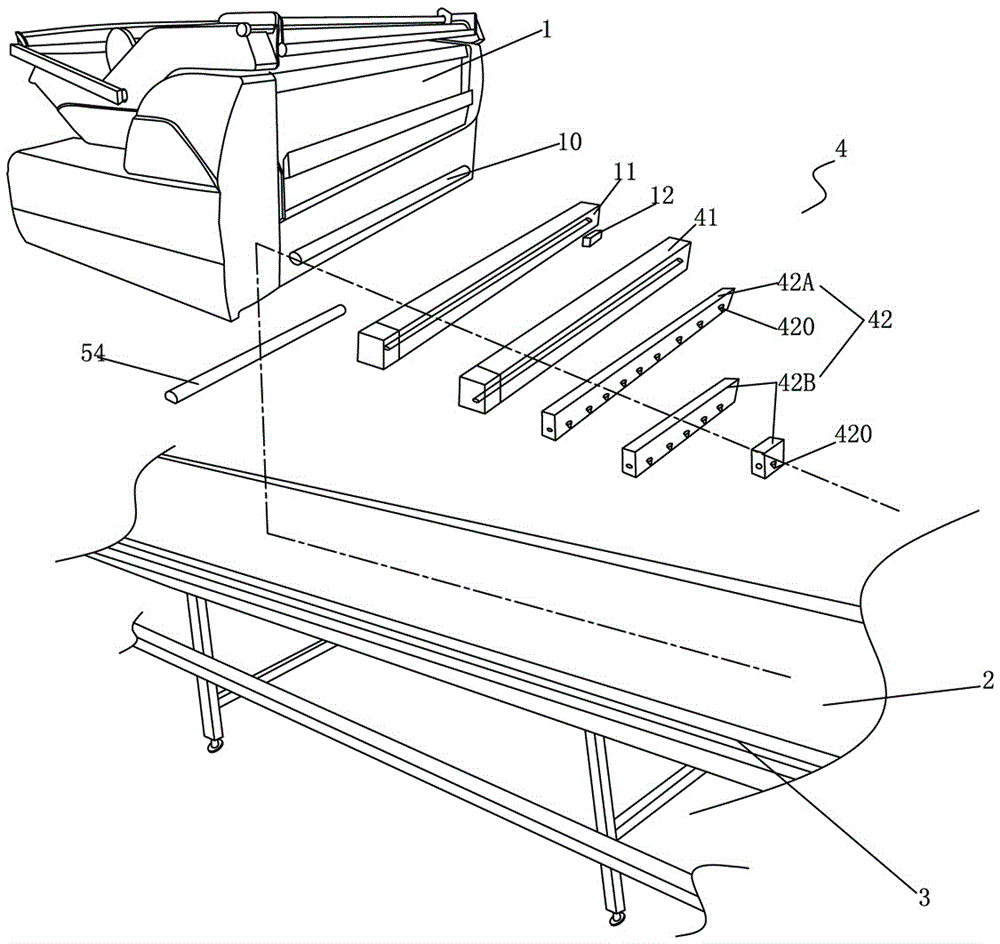

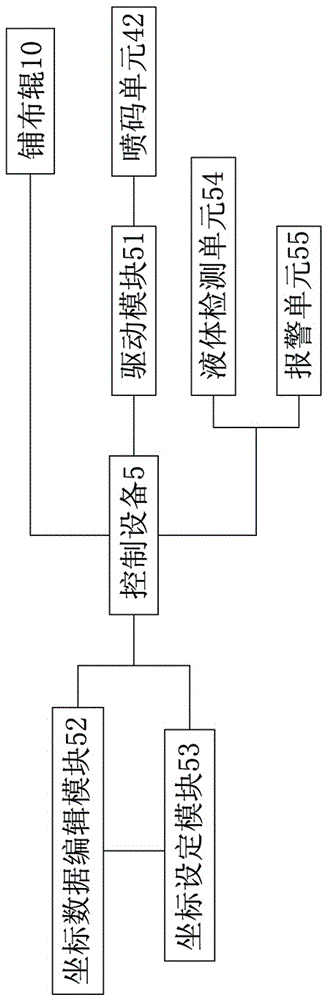

[0038] Specific implementation methods, (such as Figure 1 to Figure 4 As shown) a cloth spreading device with coding function according to the present invention, which mainly includes the following components: cloth spreading machine 1, platform 2, transmission rail 3, cloth spreading roller 10, first slide rail 11, cloth cutting unit 12. The second slide rail 41, the coding axis 42A, the driving module 51, the coordinate data editing module 52, the coordinate setting module 53, the liquid detection unit 54 and the alarm unit 55;

[0039] When assembling, first, place the spreading machine 1 on the platform 2, and form a slip along the conveying rail 3; and the spreading roller 10 on the spreading machine 1 spreads the cloth on the platform 2, and the first slide rail 11 is installed on the front side of the spreading roller 10, and the cloth cutting unit 12 is installed on the first slide rail 11. After the spreading roller 10 lays the cloth to a set length, the cloth cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com