Novel paint brushing device

A technology for spraying equipment and coatings, applied in the direction of coatings, devices for coating liquids on surfaces, etc., can solve problems such as working environment pollution, uneven painting, waste, etc., and achieve broad market prospects, wide application range, and cost of use. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

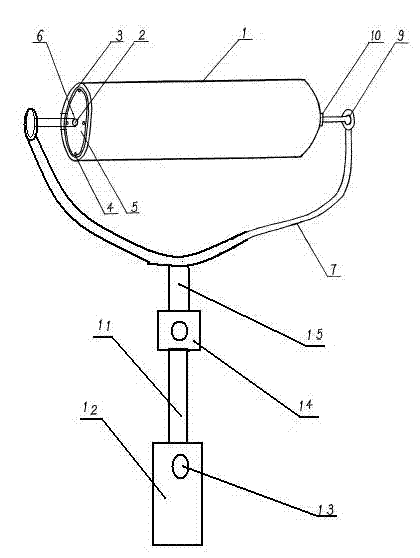

[0010] Such as figure 1 As shown, a new type of paint spraying equipment includes: a sponge roller outer layer 1, a central rotating shaft 2, a plastic sleeve 3, a support rod 7, and a telescopic brush rod, and the sponge roller outer layer 1 is provided with a plastic sleeve 3 , the plastic sleeve 3 can be a white plastic tube, and its inner wall is uniformly provided with support ribs 4 at coaxial intervals around its inner wall; The casing 3 connects and fixes the supporting ribs 4, the plastic casing 3 and the outer layer 1 of the sponge roller to form an integrated body, effectively protecting the plastic casing 3 and the outer layer 1 of the sponge roller; The two ends of the positioning disc 5 are respectively fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com