Production process of red date ice wine

A production process and jujube technology, which is applied in the field of wine making technology, can solve the problems that affect the development and promotion of jujube wine products, low nutritional value and medicinal value, and the jujube flavor of jujube wine is not strong, so as to improve the utilization rate and reduce the nutrition. Loss of ingredients, effect of improving flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

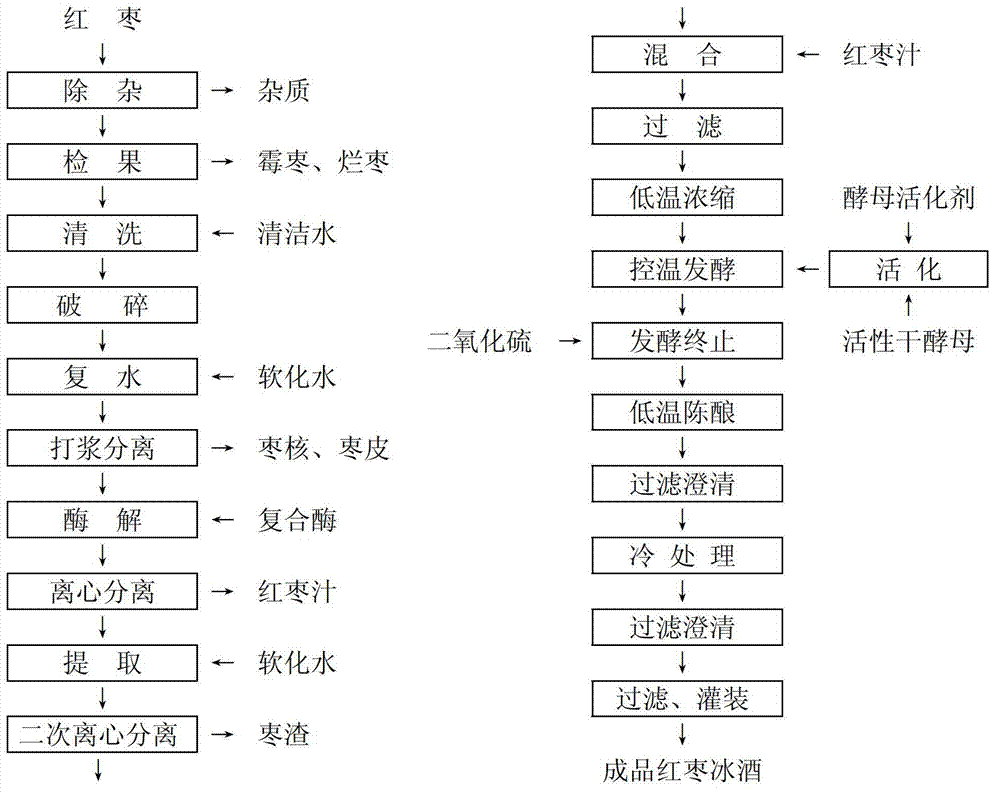

Image

Examples

Embodiment 1

[0066] A kind of production technology of jujube ice wine comprises the following steps:

[0067] (1) Impurity removal, fruit inspection, cleaning

[0068] Remove the leaves, ridges and other sundries in the jujube raw materials, select the jujubes with pests, mildew and broken, and then clean them to remove the silt attached to the surface of the jujubes, and finally wash and drain them with clean water;

[0069] (2) Crushing and rehydration

[0070] The cleaned red dates are sent to the crusher for coarse crushing. During the crushing process, only the pulp of the red dates is broken to keep the core intact. Then they are sent to the rehydration tank, and softened water at 55°C is added according to the ratio of material to water 1:5. Maintained for 60 minutes at a temperature of 50°C;

[0071] (3) beating and separation

[0072] Send the rehydrated jujube pulp into the double-channel beater, the upper part of the first beater screen discharges the date core and large pie...

Embodiment 2

[0101]All the steps of this embodiment: (1) impurity removal, fruit inspection, cleaning; (2) crushing, rehydration; (3) beating and separation; (4) enzymatic hydrolysis; (5) centrifugal separation; (6) extraction; (7) secondary centrifugal separation; (8) filtration; (9) low-temperature concentration; (10) yeast activation; (11) temperature-controlled fermentation; (12) fermentation termination; (13) low-temperature aging; (14) filtration clarification; (15) Cold treatment; (16) Sterile filtration, filling. Except (6) the temperature and time in the extraction step were changed to 90°C for 120 minutes, (9) the concentration of jujube clear juice was changed to 360g / L (based on glucose) in the low-temperature concentration step, and (11) temperature-controlled fermentation In the step, the temperature and time were changed to 16° C., the fermentation time was 45 days, and the rest of the process conditions were the same as in Example 1.

[0102] The product that present embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com