Non-lauric non-trans fat composition for chocolate coating

一种油脂组合物、巧克力的技术,应用在食用油/脂肪、应用、食物科学等方向,能够解决问题等问题,达到结着性提高、新颖且绵柔口感的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、 Embodiment 2、 Embodiment 3

[0151] (Example 1, Example 2, Example 3, Comparative Example 1, Comparative Example 2)

[0152] (preparation of grease)

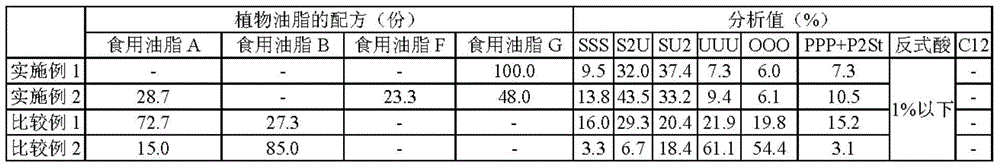

[0153] The vegetable oil fraction was prepared separately according to the following recipes. Wherein, embodiment 3 is prepared with the same formula as embodiment 1. Table 2 shows the oil formula, the analysis results of triglyceride composition obtained by HPLC, the content of trans acid and the content of C12.

[0154] [Table 2]

[0155]

[0156] (prototype chocolate)

[0157] Next, according to the following recipe, use the usual method to try out the chocolate.

[0158] Embodiment 1, embodiment 2 and comparative example 1, comparative example 2 are the same formula that only the vegetable oil part to be formulated is different, and embodiment 3 is trial-produced with the same formula as embodiment 1 except whether there is sucrose fatty acid ester.

[0159] The trial-produced chocolate was coated on donuts and evaluated according to the evaluat...

Embodiment 4、 Embodiment 5、 Embodiment 6、 Embodiment 7

[0166] (Example 4, Example 5, Example 6, Example 7, Comparative Example 1)

[0167] (preparation of grease)

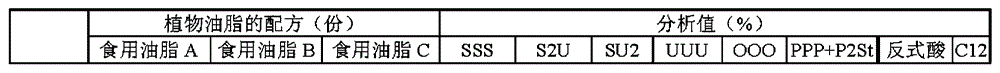

[0168] According to the following recipes, the vegetable oil fractions were prepared separately. Wherein, embodiment 7 is prepared with the same formula as embodiment 1. Table 4 shows the oil formula, triglyceride composition analysis results obtained by HPLC, trans acid content and C12 content.

[0169] [Table 4]

[0170]

[0171]

[0172] (prototype chocolate)

[0173] Next, according to the following recipe, use the usual method to try out the chocolate.

[0174] Examples 4 to 6 and Comparative Example 1 are the same formulation except for the vegetable oil part to be formulated. Example 7 is trial-produced with the same formulation as Example 4 except for the presence or absence of sucrose fatty acid ester.

[0175] The trial-produced chocolate was coated on donuts and evaluated according to the evaluation method described above.

[0176] Both Examples ...

Embodiment 8、 Embodiment 9

[0184] (preparation of grease)

[0185] According to the following recipes, the vegetable oil fractions were prepared separately. Table 6 shows the oil formula, the analysis results of triglyceride composition obtained by HPLC, the content of trans acid and the content of C12.

[0186] [Table 6]

[0187]

[0188] (prototype chocolate)

[0189] Next, according to the following recipe, a trial production of chocolate was carried out by the usual method.

[0190] Example 8 and Example 9 were trial-manufactured with the same formulation that only differed in oil and fat composition.

[0191] The trial-produced chocolate was coated on donuts and evaluated by the above-mentioned evaluation method.

[0192] Example 8 and Example 9 contained fats and oils that were liquid at room temperature in addition to fats and oils with an elevated melting point of 35° C. or higher. Furthermore, SU2 is 30 weight% or less, and UUU is 10 weight% or more.

[0193] Example 8 containing more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com