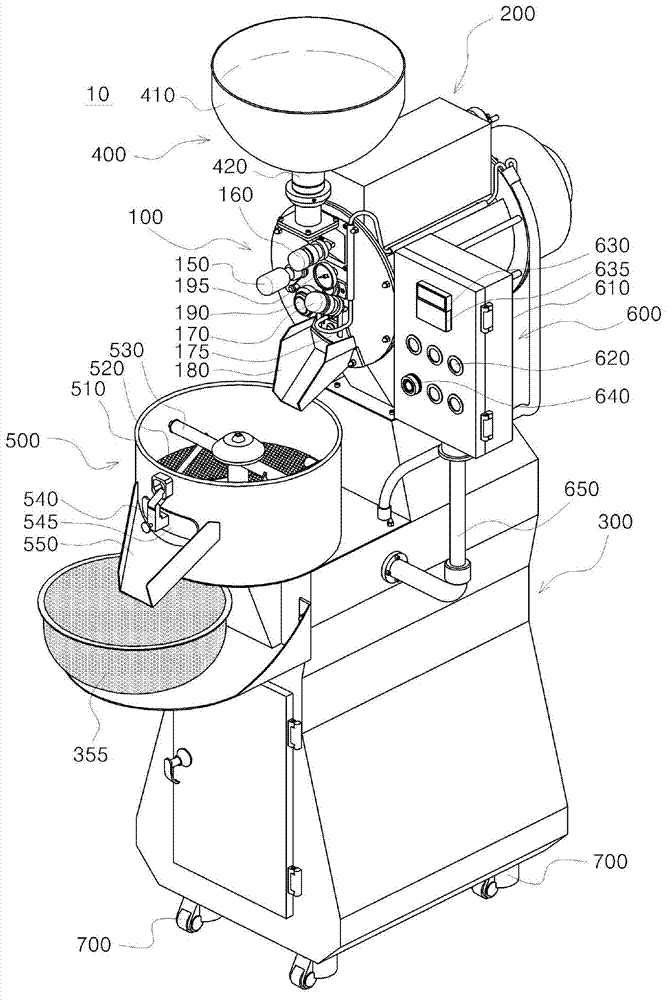

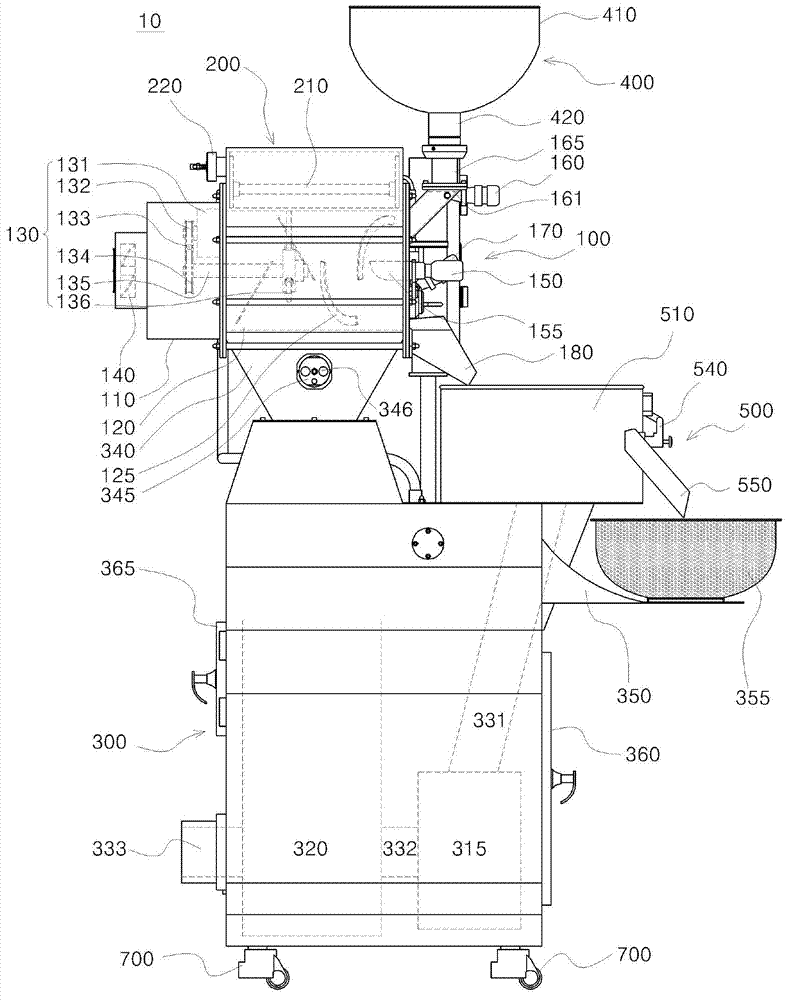

Roaster

A roaster and roasting technology, applied in roaster/barbecue grids, household appliances, food processing, etc., can solve the problems of coffee bean damage, different degrees of coffee heat transfer, and inability to uniformly roast coffee beans, etc. The effect of quality, improved baking efficiency and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

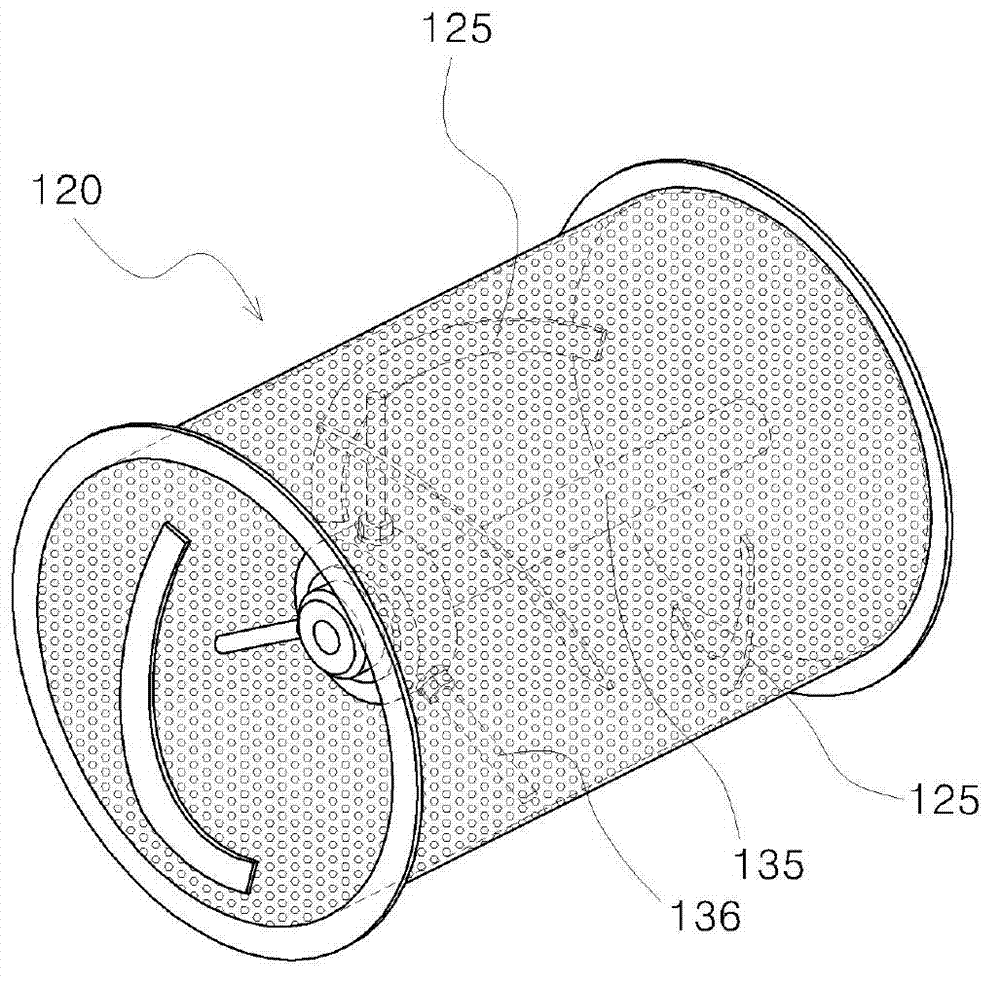

[0057] Hereinafter, the present invention will be described in more detail through examples. Through the following examples, the purpose, characteristics and advantages of the present invention can be easily understood. The present invention is not limited to the embodiments described here, but may be embodied in other forms. The embodiments described here are provided to make the disclosure clear and complete, and to enable those skilled in the art to fully understand the inventive concept. Therefore, the present invention is not limited by the following examples.

[0058] In order to make the present invention more clearly understood, the size of components in the drawings or the relative size between components may be somewhat exaggerated. In addition, the components shown in the drawings may vary somewhat due to differences in the manufacturing process. Therefore, unless otherwise indicated, the embodiments disclosed in this specification are not limited to the shapes sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com